Best Price Waterproof Geomembrane 2mm with Geotextile Woven & Non Woven

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description:

Made from MDPE and HDPE resin by blow film process

Application:

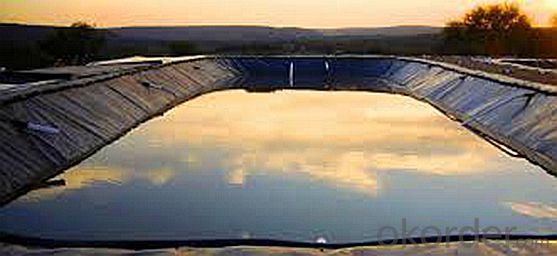

1.Municipal environmental projects, water conservancy projects

2.Anti-seepage projects for transportation infrastruture

3.Agricultural water conservancy projects

4.Water proof engineering for aquaculture,Irrigation ditch, ponds and reservoir,landfill

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

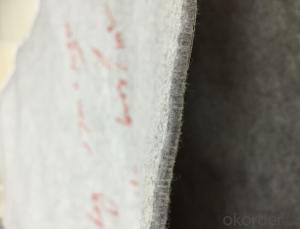

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used for reinforcement of bridge abutments?

- Yes, geotextiles can be used for the reinforcement of bridge abutments. Geotextiles are commonly used in civil engineering projects for soil stabilization and erosion control. When applied to bridge abutments, geotextiles can help enhance the structural integrity and stability of the soil, preventing erosion and reducing the likelihood of settlement or shifting of the abutments. By acting as a barrier between the soil and the abutment, geotextiles distribute loads more evenly, increasing the overall strength and durability of the bridge structure.

- Q: What is the high strength to strengthen the composite geotextile

- The correct product name should be high-strength reinforced composite geotextile This is a different from the traditional geotextile new products. Reinforced geotextile is made of high-strength fiber tow and non-woven composite weaving, the process is arranged in parallel fiber bundles, give full play to the role of the yarn. Non-woven mat under which the warp technology will be wrapped around the bundle, so that fiber tow and non-woven together, not only to keep the non-woven filter, but also has the strength of woven cloth. Mainly used in: rivers and lakes, drains, reservoir dam control project and power plant ash dam, mine, airport, cargo yard, railway, highway, tunnel, municipal, environmental protection and other projects, with reinforcement, isolation, Drainage, protection and other functions, is an excellent geotechnical materials; the main role is to seepage and isolation of the grassroots level, to prevent soil erosion, sand, and the embankment foundation of the embankment increased tolerance. The superiority is mainly manifested in the following aspects: high strength composite reinforced geotextile anti-aging durability, the service life can reach and more than 100 years; high strength composite geotextile puncture high strength, physical indicators far more conventional geosynthetics Material strength index; high strength composite geotextile friction coefficient, the adhesion is particularly strong, increasing the adhesion of the isolation layer, taking into account the external factors on the impact of reinforced filter layer reduced; high-strength composite geotextile reinforced acid, alkali , Salt corrosion, in the low temperature and high temperature and UV anti-aging experiments, the physical indicators stable.

- Q: The difference between the construction hdpe impermeable membrane and the geotextile

- Hello, this is two different products Geotextile is not seepage, but the role of filtered water HDPE geomembrane is waterproof. Huazhi geotechnical materials manufacturers to answer your questions

- Q: How to judge the geotextile test results are reliable

- Determine whether the tensile test results of the material are reliable, depending on whether the tensile process of the material to be tested during the test has reached the state required by this detection method. As a tensile test, to test the tensile strength and elongation of the material under specified conditions. Stretching process, the material to be tested to be uniform force, the test machine fixture holding the sample to be solid, the sample does not produce slip nor be caught damage. This is the test process of the requirements of the test machine fixture and the installation of the sample requirements, only to meet this requirement and other requirements, the test results may be accurate. Geotechnical composite materials - Geosynthetics - Staple acupuncture non - woven geotextiles GB / T-1998 Geosynthetics - Filament spunbonded acupuncture non - woven geotextiles GB / T - 1998 Geosynthetics Geosynthetics - Geosynthetics - Geosynthetics - Geosynthetics - Geosynthetics - Geosynthetics - Geosynthetic materials GB / T - 1998 Geosynthetics - Geological synthetic materials Polyvinyl chloride geomembrane GB / T-1999 Geosynthetics Plastic geogrid GB / T-1999 Geosynthetics Plastic flat wire braided geotextiles GB / T-2002 Geosynthetics Plastics 3D geogrids GB / T-2002 geosynthetics / outer composite geotextile

- Q: What are the different geotextile testing parameters?

- There are several different geotextile testing parameters that are used to evaluate the performance and quality of geotextiles. Some of the common parameters include tensile strength, puncture resistance, tear strength, permeability, apparent opening size, and UV resistance. These tests help determine the suitability of geotextiles for specific applications and ensure their durability and effectiveness in various geotechnical and civil engineering projects.

- Q: What are the different factors to consider when selecting a geotextile?

- When selecting a geotextile, there are several factors to consider. These include the intended application or function of the geotextile, the site conditions and soil characteristics, the required strength and durability, the installation and maintenance requirements, and the cost-effectiveness of the geotextile. Additionally, factors such as compatibility with other materials, environmental considerations, and regulatory requirements may also need to be taken into account.

- Q: What are the specifications for geotextiles in wastewater treatment projects?

- The specifications for geotextiles in wastewater treatment projects typically include requirements for strength, filtration efficiency, and durability. Additionally, they may specify the type and weight of geotextile fabric to be used, as well as any necessary certifications or testing standards that need to be met. Geotextiles used in wastewater treatment projects are typically designed to provide effective filtration and separation of solids, while also being resistant to chemical degradation and capable of withstanding the harsh conditions present in wastewater treatment facilities.

- Q: Can geotextiles be used in geosynthetic clay liner caps?

- Yes, geotextiles can be used in geosynthetic clay liner caps. Geotextiles are often used as a protective barrier or separator in geosynthetic clay liner systems to enhance their performance and prevent clogging or migration of fine particles.

- Q: What are the factors to consider when selecting geotextiles?

- When selecting geotextiles, factors to consider include the desired application, site conditions, required strength and durability, permeability, cost, and environmental considerations.

- Q: Polyester geotextile filter layer sets what the amount

- Polyester filament geotextile Features: Polyester filament geotextile is made by polyester method by spinning acupuncture consolidation directly made, product specifications from 80-800g / m2 arbitrary choice, it is geotechnical engineering and civil engineering In the application of a geosynthetics, polyester filament into a network and consolidation method, the fiber arranged in three-dimensional structure. In addition to good mechanical properties, but also has a good vertical and horizontal drainage performance and good extension properties and high resistance to biological, acid and alkali, anti-aging and other chemical stability. At the same time, it also has a wide pore size range, tortuous pore distribution, excellent permeability and filtration performance. Polyester filament geotextile Uses: water conservancy project dam and slope protection of the filter, channel isolation, seepage; road, rail, airport runway foundation isolation, filter, drainage, slope, retaining wall and road reinforcement, Drainage; Port Engineering soft foundation treatment, traces of the tube of the river alone sweeping the beach embankment, harbor wharf and breakwater reinforcement, drainage; polyester filament geotextile has been widely used in the field of infrastructure construction, and gradually applied In a wider area.

Send your message to us

Best Price Waterproof Geomembrane 2mm with Geotextile Woven & Non Woven

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords