Geotextil Preis Polyethylene HDPE Geomembrane as Waterproof Facing of Earth

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

HDPE Geomembrane

Thickness: 1.0mm to 3.0mm

Roll Size: 4m-9m in width

roll length as design or client’s request

geomembrane hdpe

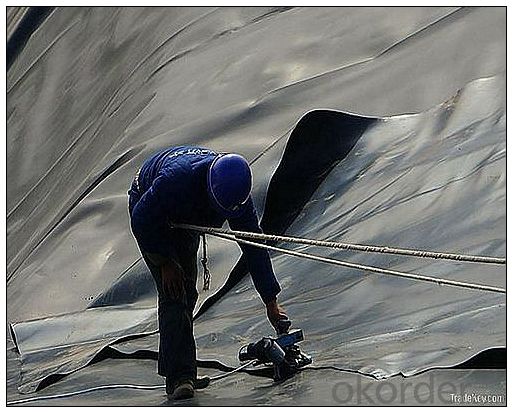

Geo-membrane is produced by a method of three layer co-extrusion model. The raw material is processed at 200°C by fusing and coextrusion, whose basic properties are kept during the producing process.

Strengths

Environmental Stress & Crack Resistance

Water Resistance

Chemical Resistance

UV and Thermal Weathering Resistance

Conformation to sub-soil movements

Tear Resistance

Puncture Resistance

Repairable

Recyclable

Very low permeability

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used in erosion control mats?

- Yes, geotextiles can be used in erosion control mats. Geotextiles are often used as a primary component in erosion control mats to prevent soil erosion by improving stability, drainage, and filtration.

- Q: How do geotextiles improve the performance of dams?

- Geotextiles improve the performance of dams by providing reinforcement, filtration, and erosion control. They can enhance the stability of the dam structure by acting as a barrier against seepage and offering additional support. Geotextiles also act as a filter to prevent the migration of fine particles through the dam, ensuring its long-term integrity. Additionally, they help in controlling erosion by stabilizing the soil and preventing the washout of material from the dam surface.

- Q: What are the specifications of the garage roof using geotextiles?

- Generally with 200g or 300g, I professional production, wish smooth

- Q: There are engineering budgets

- Geotextile to polypropylene or polyester and other chemical fiber made of raw materials, to acid and alkali, no corrosion, no moth, anti-oxidation. It is widely used in the field of civil engineering, its main application areas are: 1. Highway, railway, airport, building and other engineering foundation reinforcement treatment; use of geotextile to enhance the soil tensile strength and resistance to deformation, Concentrate the stress spread, transfer or decomposition, to prevent the soil by external force and damage. Enhance the stability of the building structure to improve soil quality. 2. dam and other slope protection project; the use of geotextile good permeability and water permeability, so that water flow through, and thus effectively cut off the loss of sand. Geotextile mesh should not be blocked - due to the formation of amorphous fibrous tissue structure and strain and mobility. Has a good conductivity of water, it can make the formation of drainage within the soil channel, the soil structure of excess liquid and gas exclusion. 3 .. road maintenance works; the use of geotextile isolation characteristics to prevent the upper and lower gravel, soil and concrete mixed between. If you really have the confidence to do sales I can try to support the specific telephone consultation Yinjing Li

- Q: How do geotextiles contribute to pavement performance?

- Geotextiles contribute to pavement performance by improving the overall strength and durability of the pavement. They act as a reinforcement layer, preventing the migration of fine particles and providing separation between the subgrade and base layers. This helps to distribute the load evenly, reduce pavement deformation, and increase its resistance to cracking and rutting. Additionally, geotextiles can enhance drainage and reduce water infiltration, preventing moisture-related issues such as frost heave or base erosion. Overall, geotextiles play a crucial role in enhancing the longevity and performance of pavements.

- Q: How do geotextiles help in preventing piping in dams?

- Geotextiles help in preventing piping in dams by providing a strong and stable barrier against soil erosion. They are placed within the dam structure to reinforce the soil and prevent it from being washed away by the flow of water. This helps in maintaining the integrity of the dam and preventing the formation of internal erosion channels or "piping". Geotextiles also improve the filtration properties of the soil, allowing water to pass through while retaining fine particles, which further helps in preventing piping.

- Q: What are the different geotextile installation guidelines?

- Geotextile installation guidelines typically include steps such as site preparation, ensuring proper placement and alignment, securing the geotextile in place, and properly overlapping or joining adjacent sections. Additionally, specific guidelines may be provided for different applications, such as road construction, erosion control, or drainage systems, to ensure optimal performance and longevity of the geotextile.

- Q: How do geotextiles help in reducing the risk of slope failures?

- Geotextiles help in reducing the risk of slope failures by providing reinforcement and stabilization to unstable slopes. These materials are placed within the slope to increase its strength and prevent erosion. Geotextiles also help in promoting water drainage and filtration, which reduces the build-up of hydrostatic pressure within the slope. Overall, geotextiles enhance the stability of slopes and mitigate the potential for landslides or slope failures.

- Q: Can geotextiles be used in the protection of embankments?

- Yes, geotextiles can be used in the protection of embankments. Geotextiles are commonly used as a reinforcement material to stabilize the soil and prevent erosion on embankments. They can help to improve the overall strength and stability of the embankment by increasing its resistance to water flow and reducing the potential for slope failure. Additionally, geotextiles can promote vegetation growth, further enhancing the embankment's stability and protecting it from erosion.

- Q: JTGF80 / 1-2004 "standard" 4.5 Geosynthetics in the treatment of the measured items in the "anchoring length", in the construction design diagram, the provisions of the value of the allowable deviation should be how to implement? Question added: Sorry! I missed a few words. When the construction design is not indicated, the specified value, the allowable deviation value should be implemented? JTGF80 / 1-2004 "standard only write to meet the design, construction requirements. I did not say that the design of the length of the anchorage is how much, can not find the construction technical specifications. So I do not know the provisions of the value of how to allow deviation? More

- Specifically not less than the specified value, does not exceed the allowable deviation. This is the so-called construction by specification! You refer to JTG assessment standard -2004 is correct! I have the data to let you refer to the next / geogrid and geotextile landscape is greater than or equal to 50cm, vertical is greater than or equal to 150com

Send your message to us

Geotextil Preis Polyethylene HDPE Geomembrane as Waterproof Facing of Earth

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords