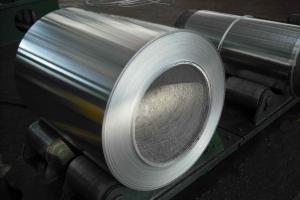

Berger Aluminum Coil - CC Aluminium Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Excellent service

2.Prime quality

3.Cuick delivery

3.ISO 9001:2008

4.BV ,SGS ,

Factory price high quality aluminum coil

Substrates: | Aluminium (1100, 3003, 3004, 3105, 5006, 5052, 8011, etc), etc. |

Thickness: | 0.08-1.5mm |

Width: | <1800mm |

Coils core diameter: | 150mm ,405mm, 505mm, 508mm, 510mm |

Coating thickness: | PVDF >=25micron POLYESTER>=18micron |

Color standard: | E < 2 or it is not obvious by eyeballing |

Pencil hardness: | > 2HB |

Coating adhesive: | not lower than first grade Impact: no any crack (50kg/cm, ASTMD-2794:1993) |

Bend strength: | >100 times |

Boiling point: | no any distortion and color change (in the 99 more or less 1 degree water, then cooling 2 hours) |

Corrosive: | surface deep in the 5% muriatic acid and 5% NaCL, interior deepin the 2% muriatic acid and 2% NaCL, after 48 hours, no change |

- Q: I'm doing a science project on Aluminum and need to know what the other metals are in the following ores:BauxiteCryoliteGibbsiteI have to know what percentage of it is which metal. Don't know if that makes much sense, but I really need help because I can't find the answer anywhere. Thanks :D

- The bauxite is a sedimentary rock of chemical origin composed for the most part by alumina (Al2O3) and, in smaller measure, iron oxide and silica. It is the main aluminum source used by the industry. It is a residual taken place by the meteorización of the igneous rocks under conditions geomorfológicas and climatic favorable. Molecular formula: Na3AlF6 Synonym: Fluoroaluminato of sodium. Chemisorption of catechol on gibbsite, boehmite, and noncrystalline alumina... Alumina; Aluminium Oxyhydroxyde

- Q: How are aluminum coils protected against bending and warping during storage?

- Aluminum coils are protected against bending and warping during storage through various measures and precautions. Firstly, the coils are typically stored in a horizontal position to evenly distribute the weight and minimize stress on the coil. This helps to prevent any bending or warping that could occur if the coils were stored vertically. Additionally, the coils are often wrapped in protective materials such as plastic or paper to provide a barrier against external forces that could cause damage. These protective wrappings help to cushion the coils and prevent any direct contact with hard surfaces that could result in bending or warping. Furthermore, it is common practice to stack the coils carefully and securely, ensuring that they are not overloaded or subjected to excessive pressure. This is done to maintain the structural integrity of the coils and prevent any deformation during storage. Temperature control is another important aspect in protecting aluminum coils against bending and warping. Extreme temperature fluctuations can cause the metal to expand or contract, potentially leading to warping. Therefore, the storage environment should be maintained at a stable temperature to minimize any thermal stress on the coils. Overall, a combination of proper handling, protective wrappings, secure stacking, and temperature control play crucial roles in preventing bending and warping of aluminum coils during storage. These measures ensure that the coils remain in optimal condition and are ready for use when needed.

- Q: Is it possible to create baskets or containers using aluminum coils?

- <p>Yes, aluminum coils can be used to make baskets or containers. Aluminum is a lightweight, durable, and malleable material that can be easily shaped and bent into various forms. It is commonly used in manufacturing due to its strength and resistance to corrosion. For baskets or containers, aluminum coils can be woven or molded into the desired shape, offering both functionality and aesthetic appeal. However, it's important to consider the thickness and gauge of the aluminum to ensure the structure's stability and durability for its intended use.</p>

- Q: What are the different types of alloys used for aluminum coils?

- There are several different types of alloys that are commonly used for aluminum coils. The most commonly used alloy for aluminum coils is 3003. This alloy is known for its excellent corrosion resistance and moderate strength. It is often used in applications where high strength is not required, such as in roofing and siding. Another commonly used alloy for aluminum coils is 5052. This alloy has good weldability and formability, making it suitable for a wide range of applications. It is often used in the automotive industry for body panels and fuel tanks. 6061 is another popular alloy for aluminum coils. This alloy has excellent strength and is often used in structural applications. It is commonly used in the aerospace industry for aircraft parts and in the construction industry for structural components. Other alloys that are used for aluminum coils include 1100, 5005, and 8011. Each of these alloys has its own unique properties and characteristics, making them suitable for different applications. For example, 1100 is known for its high electrical conductivity and is often used in electrical applications, while 8011 is commonly used for packaging and food containers due to its excellent corrosion resistance. In summary, the different types of alloys used for aluminum coils include 3003, 5052, 6061, 1100, 5005, and 8011. These alloys offer a range of properties and characteristics that make them suitable for various applications across industries such as automotive, aerospace, construction, and packaging.

- Q: How do aluminum coils contribute to the aesthetics of a building?

- The versatility, durability, and aesthetic appeal of aluminum coils significantly enhance the aesthetics of a building. Firstly, aluminum coils offer flexibility in achieving the desired aesthetic by easily shaping and forming them into various architectural designs. Whether it's a sleek modern look or a more traditional design, aluminum coils can be customized to meet specific aesthetic requirements. Additionally, architects and designers have a diverse palette of colors and finishes to choose from when using aluminum coils. This wide range of options allows for endless possibilities in creating visually appealing facades and exteriors that match the overall theme or style of the building. Moreover, aluminum's durability and resistance to corrosion make it an ideal material for architectural applications. By using aluminum coils, the exterior surfaces of a building can maintain their aesthetic appeal for an extended period with minimal maintenance required. This long-lasting beauty makes aluminum coils a cost-effective choice for maintaining the aesthetics of a building. Furthermore, aluminum coils contribute to the energy efficiency of a building. They have excellent thermal conductivity, which effectively dissipates heat and reduces energy consumption for temperature control. This energy-saving feature not only enhances the sustainability of a building but also adds to its overall aesthetic appeal by incorporating environmentally conscious design elements. In conclusion, the use of aluminum coils in a building contributes to its aesthetics through design flexibility, a wide range of color and finish options, durability, and energy efficiency. These qualities allow architects and designers to create visually appealing structures that align with the desired aesthetic vision while ensuring long-lasting beauty and sustainability.

- Q: How do aluminum coils compare to other materials in terms of strength?

- Known for their remarkable strength-to-weight ratio, aluminum coils are highly competitive when compared to other materials. While aluminum may not be as strong as metals like steel or titanium, it still possesses sufficient strength to meet the demands of various applications. The strength of aluminum coils, relative to their weight, is often superior to that of other materials. Furthermore, aluminum coils exhibit exceptional corrosion resistance, enhancing their durability and longevity. Despite the availability of stronger materials, aluminum coils continue to be an excellent choice for many industries due to their favorable strength characteristics and numerous other benefits.

- Q: I heard that one pound of aluminum pop tabs are worth more then a pound of aluminum pop cans. Is this true? Thank you.

- actuality. You ask a question with constrained area and then want information to help. what number information do you have time and area for? first of all, the Bible has been used for geographic accuracy. 2nd, this is been used for archaeological accuracy. 0.33, this is been used for historic accuracy. The Bible pronounced the earth became around approximately 700BC in the past astronomers knew it. Many have wondered the Bible at circumstances even with the undeniable fact that those questions blow away. occasion, scientists wondered regardless of if the Hittites have been a genuine those that have been pronounced interior the Bible till archaeologists chanced on pictures and inscriptions at some websites.The Bible has survived many tries at burying it or destroying it. i.e. the Romans, the Catholic Church, purges, and extreme persecution of its adherents.The Romans have been famous for his or her tortures for 315 years yet Christianity based on the Bible grew besides! i will advise 5 staggering books that answer this authoritatively interior the source section. That technology is named Apologetics. this may well be an excellent, significant question -demands an excellent answer.

- Q: Are aluminum coils suitable for outdoor applications?

- Yes, aluminum coils are suitable for outdoor applications. Aluminum is known for its excellent corrosion resistance, making it a popular choice for outdoor use. It is not prone to rust or deterioration when exposed to moisture, sunlight, or harsh weather conditions. Additionally, aluminum coils are lightweight, durable, and have a high strength-to-weight ratio, making them ideal for various outdoor applications such as roofing, gutters, air conditioning systems, and outdoor furniture. Moreover, aluminum is a highly recyclable material, making it an environmentally-friendly choice for outdoor projects. Overall, aluminum coils are a reliable and practical option for outdoor applications.

- Q: Is there aluminum coil of 44mm wide and 0.40mm thick?

- The common width of aluminum coil is 1000mm or 1220mm. If you want 0.4mm*1000MM aluminum coil, you can strip 0.4mm*1000MM aluminum coil.

- Q: What is the difference between aluminum plate and aluminum coil?

- A sheet is flat, one by one for storage, one for coil material, one roll for storage, but aluminum coil can be leveled by machine, that is aluminum plate.

Send your message to us

Berger Aluminum Coil - CC Aluminium Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords