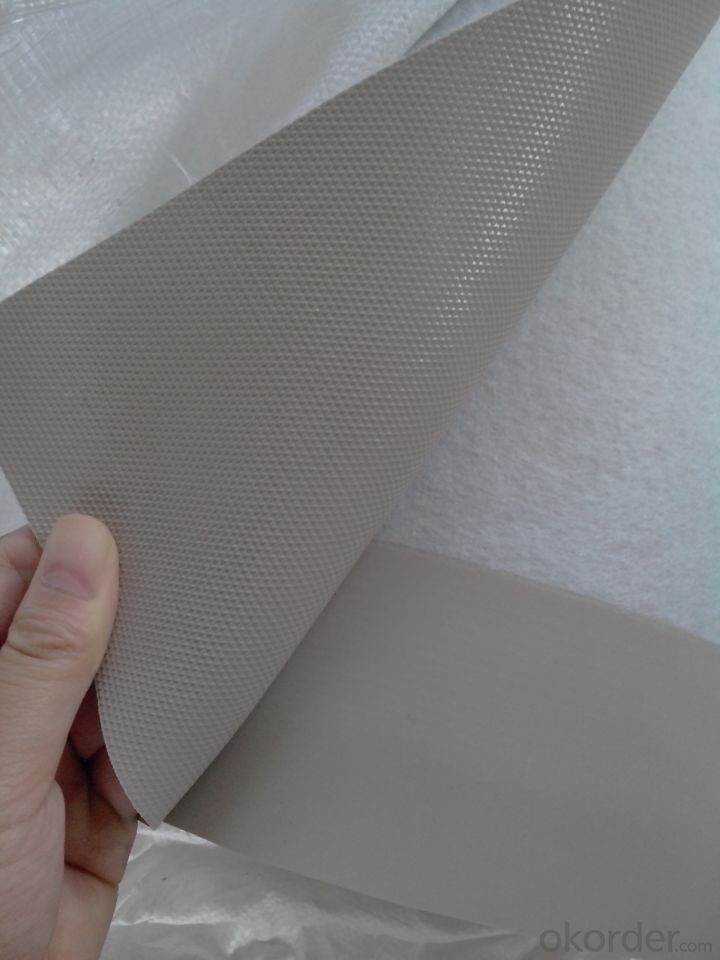

Basement PVC Reinforced Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Polyvinyl Chloride (PVC) waterproof membrane is a new polymer waterproof membrane which is made from polyvinyl chloride resin, and mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Features

1. Good combination of high elasticity and tensile strength.

2. Fine resistance to static electricity.

3. Excellent resistance to ageing / weathering.

4. Durable, the effective age can be more than 20 years used on exposed surfaces, used on non-exposed surfaces, it can reach 50 years.

5. Fine flexibility at low temperature, adaptable to cold conditions.

6. Root-resistance can be used on the planting roofs.

7. Fine puncture resistance, joint peel strength and joint shear strength.

8. Fine UV-resistance, no pollution to environment.

9. Easily welding, installing, secure.

10. Easy treatments to the delicate parts of corners and edges.

11. Convenient maintenance with low cost.

Specification

No | Item | I | II | |

1 | Tensile strength/ Mpa | 8.0 | 12.0 | |

2 | Fracture elongation / % ≥ | 200 | 250 | |

3 | Heating flexibility / % ≤ | 3.0 | 2.0 | |

4 | Cold bending | -20°C No leaking | -25°C No leaking | |

5 | Water impermeability | Water impermeable | ||

6 | Binding property with cutting (N/mm) | 3.0/ breaking membrane | ||

7 | Hot air ageing | Appearance | No craze, no bubble, no cohering, hole | |

Tension strength % | ±25 | ±20 | ||

Fracture elongation changing rate | ||||

Cold bending % | -15°C No leaking | -20°C No leaking | ||

8 | Chemistry corrosion resistance | Tension strength % | ±25 | ±20 |

Fracture elongation changing rate | ||||

Cold bending % | -15°C No leaking | -20°C No leaking | ||

9 | Phytotrons accelerating ageing | Tension strength % | ±25 | ±20 |

Fracture elongation changing rate | ||||

Cold bending % | -15°C No leaking | -20°C No leaking | ||

10 | Note: no considering phytotrons accelerating ageing. | |||

Application

Colorful polymer PVC waterproof membrane can variously be used on the roof of building, underground building, tunnel, dam, pool, sewage treatment works, and garbage disposal facilities. It also can be suitable to any requirement of all kinds of technological practice & different grade of roof waterproof and underground constructions waterproof.

RFQ

1. What is your MOQ?

--Our MOQ is 5000 m2

2. Can you provide sample?

--Yes, samples are in stock. we can offer free sample for you.

3. Do you offer OEM service?

--Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: Can a waterproofing membrane be installed on a concrete foundation?

- Installing a waterproofing membrane on a concrete foundation is indeed a common practice. This is done to prevent water infiltration and safeguard the structure from moisture-related harm. Typically, the membrane is applied to the exterior surface of the foundation walls, serving as a barrier against water and moisture. The type of membrane used can vary, ranging from liquid-applied to sheet membrane or a combination of both, depending on the project's specific requirements. Its purpose is to act as a protective layer, preventing water from penetrating the foundation and causing issues like dampness, mold growth, and structural decay. By incorporating a waterproofing membrane into a concrete foundation, homeowners and builders can guarantee the structure's long-term durability and integrity.

- Q: Can a waterproofing membrane be used in chemical or hazardous environments?

- Yes, a waterproofing membrane can be used in chemical or hazardous environments. Waterproofing membranes are designed to provide a protective barrier against water and moisture, and some specialized membranes are also resistant to chemicals and hazardous substances. These membranes are commonly used in industries such as manufacturing, chemical processing, and wastewater treatment plants to prevent leaks and protect against corrosion caused by chemicals. However, it is essential to select a membrane specifically designed for the particular chemicals and hazards present in the environment to ensure optimal performance and safety.

- Q: Can a waterproofing membrane be used on terracotta surfaces?

- Yes, a waterproofing membrane can be used on terracotta surfaces. Terracotta is a porous material that can absorb water, leading to potential damage and deterioration. Applying a waterproofing membrane on terracotta surfaces helps to create a barrier that prevents water penetration and protects the material from moisture-related issues. The membrane acts as a protective layer that keeps the terracotta surface dry and prevents water from seeping through. This can be particularly beneficial in areas with high moisture levels or where terracotta is exposed to water, such as in bathrooms, kitchens, or outdoor installations. It is important to choose a waterproofing membrane that is specifically designed for terracotta surfaces to ensure compatibility and effectiveness. Additionally, proper surface preparation and application techniques should be followed to achieve optimal results.

- Q: Can a waterproofing membrane be used on both horizontal and vertical surfaces?

- Yes, a waterproofing membrane can be used on both horizontal and vertical surfaces. Waterproofing membranes are specifically designed to create a barrier against water infiltration, regardless of the orientation of the surface. These membranes are commonly used in various applications, such as roofs, foundations, basements, bathrooms, and swimming pools. They are typically made of materials like bitumen, rubberized asphalt, polyurethane, or PVC, which are highly resistant to water penetration. Whether it is a horizontal surface like a roof or a vertical surface like a wall, a waterproofing membrane can effectively prevent water from seeping through and causing damage. However, it is important to ensure that the membrane is properly installed and adhered to the surface to achieve optimal waterproofing performance.

- Q: Can waterproofing membranes be used on utility manholes?

- Utility manholes can indeed benefit from the use of waterproofing membranes. These specialized membranes are specifically engineered to create a barrier against water infiltration, making them perfectly suited for areas where water is present, such as manholes. To prevent any potential damage to the structure or the utilities within, these membranes are typically applied to the walls and floors of the manhole, effectively preventing water from seeping through. This process not only maintains the integrity and functionality of the utilities, but also helps to avoid water-related issues like corrosion, leaks, and material degradation. Furthermore, waterproofing membranes offer additional protection against elements such as chemicals, gases, and soil contaminants that may be found in or around the manhole. Thus, the application of waterproofing membranes on utility manholes is a widely adopted practice to guarantee their long-term durability and functionality.

- Q: Can a waterproofing membrane be used on foam block surfaces?

- Yes, a waterproofing membrane can be used on foam block surfaces. The membrane acts as a protective barrier, preventing water penetration and ensuring the foam blocks remain waterproof.

- Q: Can a waterproofing membrane be used for a school?

- Yes, a waterproofing membrane can be used for a school. Waterproofing membranes are commonly used in various construction projects, including schools, to protect the building and its occupants from water damage. These membranes are typically applied to areas such as basements, roofs, and foundation walls to prevent water infiltration. By creating a barrier against moisture, a waterproofing membrane helps to maintain a dry and safe environment within the school, protecting against potential structural damage, mold growth, and other water-related issues. Additionally, waterproofing membranes often come with additional benefits such as insulation and soundproofing, which can contribute to a comfortable and conducive learning environment for students and staff.

- Q: Are there any specific considerations for installing a waterproofing membrane on stucco surfaces?

- Yes, there are several specific considerations to keep in mind when installing a waterproofing membrane on stucco surfaces. Firstly, it is important to ensure that the stucco surface is clean and free of any dirt, debris, or loose material before applying the waterproofing membrane. This can be done by power washing or scrubbing the surface with a stiff brush and water. Secondly, it is crucial to choose the right type of waterproofing membrane that is suitable for stucco surfaces. There are various options available in the market, such as liquid-applied membranes, sheet membranes, or peel-and-stick membranes. It is essential to select a membrane that is compatible with stucco and provides a strong and durable barrier against water penetration. Another consideration is the proper application technique. The membrane should be applied evenly and smoothly, ensuring complete coverage over the entire stucco surface. It is important to follow the manufacturer's instructions and guidelines for the specific membrane being used. Additionally, it is recommended to pay attention to the details and transitions, such as around windows, doors, vents, or other penetrations. These areas are more prone to water infiltration, so it is important to properly seal and waterproof these vulnerable points using additional techniques or products, like flashing or caulking. Furthermore, it is essential to consider the climate and weather conditions in the area. If the stucco surface is exposed to extreme temperatures or frequent freeze-thaw cycles, it is advisable to choose a waterproofing membrane that can withstand these conditions and provide long-lasting protection. Lastly, regular inspection and maintenance of the waterproofing membrane is crucial to ensure its effectiveness over time. It is recommended to periodically check for any signs of damage, such as cracking, peeling, or bubbling, and promptly address any issues to prevent water infiltration and potential damage to the stucco surface. In conclusion, when installing a waterproofing membrane on stucco surfaces, it is important to clean the surface, choose the right type of membrane, apply it correctly, pay attention to details and transitions, consider the climate, and regularly inspect and maintain the membrane for long-lasting protection against water penetration.

- Q: Can waterproofing membranes be applied in cold weather?

- Indeed, waterproofing membranes are capable of being applied in chilly conditions. Nevertheless, it is imperative to take into account several factors when carrying out the application of these membranes in low temperatures. The curing process of the membrane can be affected by cold weather, which has the potential to decelerate it. Consequently, it is of utmost importance to ensure that the surface to be waterproofed is devoid of moisture, ice, or frost prior to the application of the membrane. Furthermore, certain waterproofing products might possess specific temperature prerequisites for attaining optimal performance, thus referring to the manufacturer's guidelines becomes indispensable. In colder temperatures, the employment of specialized adhesives or primers tailored for cold weather applications may also become necessary. All in all, by adopting appropriate precautions and utilizing suitable materials, it is feasible to successfully apply waterproofing membranes in cold weather.

- Q: Can a waterproofing membrane be used on precast insulation surfaces?

- Yes, a waterproofing membrane can be used on precast insulation surfaces. A waterproofing membrane is designed to provide a protective barrier against water infiltration, and it can be applied to a variety of surfaces, including precast insulation. The membrane helps to prevent water from seeping into the insulation, which can cause damage and reduce its effectiveness. By applying a waterproofing membrane to precast insulation surfaces, you can ensure that the insulation remains dry and maintains its thermal properties over time.

Send your message to us

Basement PVC Reinforced Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords