Base Reinforcement Geogrids - Plastic Uniaxial Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

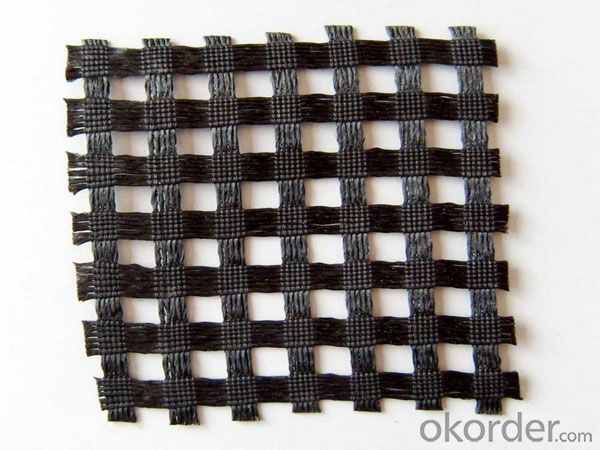

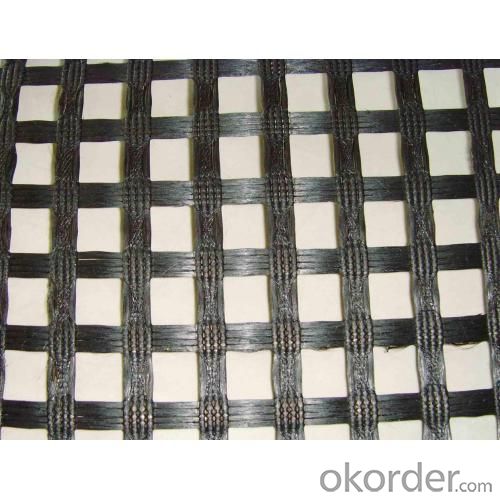

Structure of Plastic Uniaxial Geogrid Description:

Plastic Uniaxial Geogrid provide equal strengths in both machine and cross directions making them suitable for bases or foundation application where stresses can occur in any direction. Depending upon manufacturing techniques and materials, geogrids can be designed to resist creep when subjected to high loads for long periods of time or resist high, short-term dynamic loads or moderate loads over longer periods of time。

Main Features of Plastic Uniaxial Geogrid :

High tensile strength at low elongation

Optimized grid structure

Excellent pull-out and interface friction behavior

Superior connection capacity with modular blocks

Long durable years

High corrosion resistance

High flame retardancy,Fire prevention

High static conductive property

Easy in transport and installation..

Plastic Uniaxial Geogrid Images

Plastic Uniaxial Geogrid Specification:

1.Plastic Uniaxial Geogrid for Reinforced soil engineering(reinforced soil retaining wall, steep slope and the reinforcement and consolidation of the soft ground);

2.Road construction(ground treatment, reinforcement of the bridge abutment, reinforcement of the enbankment, reinforcement of the pile-net roadbed)

3. Geogrids for Irrigation projects(protection of port, approach lane, seabeach, channel, river channel, dam and other irrigation projects.)

4. Enviromental projects(land reclamation, prevention and controlling of the desertification,and the composite protective structure in the landfill sites of urban garbage and waste)

5. Mine engineering grid for long-wall recovery system(coal mines, side slope protection of opencast mines, slope protection for the dumping site of the opencast mines,reinforcement to counter dam in the large tailing ponds of the metallurgical mines)

6. Construction of stuffing and package system of heavy soil engineering

7. slope protection in the area affected by earthquake

8. Ground consolidation of large dump leaching sites and slag site

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: What are the factors that influence the design and selection of geogrids for reinforcement?

- There are several factors that influence the design and selection of geogrids for reinforcement. These include the type and characteristics of the soil, the specific application or project requirements, the anticipated loads or stresses on the geogrid, the desired design life and durability, and cost considerations. Additionally, factors such as installation conditions, site constraints, and environmental conditions may also play a role in determining the appropriate geogrid design and selection.

- Q: What are the countries of China's anti dumping

- To play the role of the application of the grid so laying hands straight smooth and uniform paving geogrid every 1.5-2.0m with hook pins fixed on the surface of 3): fill puwan grill and (48) fill every layer filling should be first on both sides, called the principle is strictly prohibited to fill embankment packing allows direct unloading of soil must have finished unloading grille paving soil surface soil unloading height to cut 1m vehicles, construction machinery directly laid geogrid embankment along the axis to allow walking driving 4) geogrid, side and from the grid layer within 8 cm to 6 cm diameter filler

- Q: Are geogrids suitable for use in seismic zones?

- Yes, geogrids are suitable for use in seismic zones. Geogrids are engineered materials that provide reinforcement and stability to soil. They are designed to improve the performance of soil structures in various conditions, including seismic events. Geogrids can help increase the tensile strength and stability of soils, reducing the risk of soil liquefaction and enhancing the overall resilience of structures in seismic zones.

- Q: How do geogrids help in load distribution?

- Geogrids help in load distribution by providing reinforcement to the soil or aggregate layers. They distribute the applied load more evenly across a larger area, reducing the concentration of stress and preventing localized failures. This allows for better load-bearing capacity and increased stability of the structure or pavement.

- Q: Soil and water conservation measures in the interim geogrid do

- First of all tell you geogrid is soil and water conservation engineering measures

- Q: Can geogrids be used in slope protection systems?

- Yes, geogrids can be used in slope protection systems. Geogrids are commonly used to reinforce slopes by providing stability and preventing soil erosion. They can be installed horizontally or vertically to improve the strength of the soil and enhance the overall performance of slope protection systems.

- Q: GSL50 what is the meaning of Geogrid

- Ministry of communications industry standard JT/480-2002 biaxial plastic geogrid GSL code, GSL50

- Q: Are geogrids suitable for use in slope stabilization for mining tailings dams?

- Yes, geogrids are suitable for use in slope stabilization for mining tailings dams. Geogrids are engineered materials that possess high tensile strength and are specifically designed to reinforce and stabilize slopes. They can effectively mitigate the risk of slope instability and erosion in mining tailings dams, providing long-term stability and safety.

- Q: Can geogrids be used in landfill liners?

- Yes, geogrids can be used in landfill liners. They are often used as part of a composite liner system to enhance the stability and performance of landfill liners. Geogrids provide reinforcement and improve the tensile strength of the liner, helping to prevent soil erosion and enhance the overall integrity of the landfill liner system.

- Q: The difference between the overlap length and the overlapping width of the geotextile in reinforced embankment

- The geotextile, which may be exposed for a long time, should be welded or stitched. All stitches must be carried out continuously (for example, point seams are not allowed). Before stitching, geotextile must overlap at least 150mm. The minimum distance of needle selvage (material exposed edge) is at least 25mm.

Send your message to us

Base Reinforcement Geogrids - Plastic Uniaxial Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords