ASTM DIN JIS Standard 1020 1045 Carbon Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

ASTM DIN JIS Standard 1020 1045 Carbon Steel

Product Information:

Material:High Quality Carbon Structural Steel 1020

Size:Diameter:10-700mm

Length:6000mm-12000mm

Origin place :Made In China

Delivery Condition:Hot rolled, cold drawn, forged

Surface require:Black, grinding, bright, polish

Heat treatment:Quenched, Tempered, annealed

Packing:Seaworthy packing ,wooden case ,carton,woven bag or at client's requires

Delivery time:According to order’s quantity.

Trade Term:EXW,FOB,CIF

Payments:T/T or L/C at sight

Port:China main Port, such as shanghai, Dalian, Shenzhen port.

MOQ:30Metric Ton

Product Overviews:

| Product Name | Typical Grades | Diameter(mm) | Standard adopted |

| Carbon Steel | 20 (1020/S20C/C22) | Ø16-Ø300 | GB/SAE/JIS/DIN |

| 40 (1040/S40C/C40) | |||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | Ø12-Ø250 | |

| GCr15 (52100/SUJ2/100Gr6) | |||

| GCr9SiMn (A485-Gr.1/SUJ3) | |||

| Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | Ø12-Ø250 | |

| 40Cr (5140/SCr440/41Cr4) | |||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | Ø16-Ø600 | |

| 20CrMn(5115/SMnC420/20MnCr5) | |||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

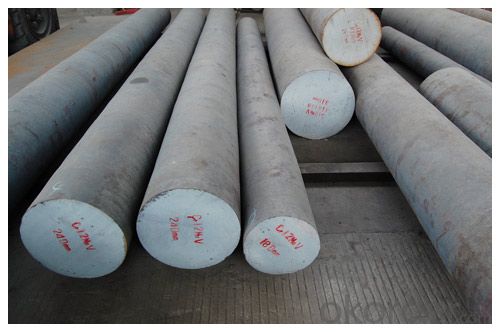

Product Show:

Our Advantages:

· Industry experience over 20 years.

· Shipment of goods -More than 70 countries worldwide.

· The most convenient transport and prompt delivery.

· Competitive price with best service.

· High technical production line with top quality products.

· High reputation based on best quality products.

With our experienced, enthusiastic and dynamic staffs, we assure to bring you the products with best quality, reasonable prices and good after-sales services under the motto: Friends First, Business After.

Communication, Experience, Expertise and Best efforts are our Promises to you.

- Q: How does special steel contribute to the aerospace aftermarket industry?

- Special steel plays a crucial role in the aerospace aftermarket industry by providing critical components that are essential for the safe and efficient operation of aircraft. The high strength, durability, and temperature resistance of special steel make it an ideal material for various aerospace applications. One of the primary ways special steel contributes to the aerospace aftermarket industry is through the production of engine components. Special steel alloys, such as nickel-based superalloys, are used to manufacture turbine blades, compressor discs, and shafts, which are vital elements of jet engines. These components must withstand extreme temperatures, pressures, and mechanical stresses, and special steel alloys offer the necessary properties to ensure reliable and long-lasting performance. Moreover, special steel is also used in the manufacturing of structural components in aircraft. Steel alloys with high strength-to-weight ratios, such as titanium alloys, are employed for the construction of critical parts like landing gear, wing spars, and fuselage frames. These components need to be both lightweight and strong to withstand the forces and stresses experienced during flight. Special steel alloys provide the required mechanical properties to ensure the structural integrity and safety of the aircraft. In addition to engine and structural components, special steel also contributes to the aerospace aftermarket industry through the production of fasteners, bearings, and other small yet vital parts. These components are responsible for holding various parts together and ensuring proper functioning of systems. Special steel alloys with excellent corrosion resistance, fatigue strength, and wear resistance are utilized to ensure the reliability and longevity of these critical components. Furthermore, special steel plays a crucial role in the maintenance, repair, and overhaul (MRO) activities of the aerospace aftermarket industry. With the rigorous demands placed on aircraft components, regular inspections, repairs, and replacements are necessary to ensure their continued airworthiness. Special steel materials are often used for MRO purposes due to their compatibility with existing aircraft systems and their ability to meet the stringent requirements of aerospace regulations. Overall, special steel is an indispensable material in the aerospace aftermarket industry. Its unique properties and characteristics enable the production of high-performance engine components, lightweight structural parts, and reliable small components. The use of special steel ensures the safety, efficiency, and longevity of aircraft, contributing to the overall success and growth of the aerospace aftermarket industry.

- Q: How does special steel perform under high-temperature conditions?

- Special steel is designed to perform exceptionally well under high-temperature conditions. It demonstrates excellent strength, toughness, and resistance to oxidation and corrosion at elevated temperatures. Additionally, special steel maintains its mechanical properties and dimensional stability even when exposed to extreme heat. Its unique composition and manufacturing techniques allow it to withstand high temperatures without significant degradation, making it ideal for applications in industries such as aerospace, power generation, and automotive.

- Q: What are the different shapes and forms in which special steel is available?

- Various shapes and forms of special steel are available to satisfy the diverse industrial and engineering needs. Some examples of special steel include: 1. Bars: Bars of special steel find extensive usage in the construction, automotive, and machinery sectors. They come in round, square, hexagonal, and flat shapes, providing design flexibility and ease of machining. 2. Sheets and Plates: Special steel sheets and plates are utilized in the production of robust components and structures. These sheets and plates are obtainable in different sizes and thicknesses, ensuring suitability for a wide range of applications. 3. Tubes and Pipes: Special steel tubes and pipes are commonly employed in industries like oil and gas, construction, and automotive. These tubes and pipes are available in various dimensions and can be either seamless or welded to meet specific requirements. 4. Wire: Special steel wire is extensively used for manufacturing springs, cables, fasteners, and other products that demand high tensile strength and corrosion resistance. It is available in different diameters and can undergo further processing techniques like drawing or annealing. 5. Forgings: Special steel can also be acquired in the form of forgings, which are shaped through controlled heating and mechanical pressure. Forgings possess exceptional strength and toughness, making them ideal for critical components in aerospace, power generation, and heavy machinery industries. 6. Castings: Special steel castings are produced by melting the steel and pouring it into molds. This casting process allows for the creation of intricate shapes and details, rendering castings suitable for applications in the automotive, energy, and mining sectors. 7. Profiles: Special steel profiles are tailor-made shapes that are specifically designed to fulfill unique engineering requirements. These profiles can be extruded, rolled, or cold-drawn, and are widely utilized in construction, transportation, and manufacturing industries. These examples merely scratch the surface of the diverse range of shapes and forms in which special steel is available. The selection of the most appropriate shape and form depends on the specific application and the desired mechanical properties required for the final product.

- Q: How does special steel contribute to the construction machinery industry?

- Special steel plays a crucial role in the construction machinery industry by providing high-strength and durable components. These components are essential for heavy-duty applications in construction machinery, such as excavators, bulldozers, cranes, and loaders. One of the key contributions of special steel to the construction machinery industry is its ability to withstand extreme stress and load-bearing requirements. Construction machinery often operates under severe conditions, including heavy loads, vibrations, and impacts. Special steel, with its excellent mechanical properties, can resist these conditions and maintain its structural integrity, ensuring the safety and reliability of the equipment. Moreover, special steel is often used in critical components of construction machinery, such as booms, buckets, tracks, and gears. These components are subjected to intense wear and tear due to constant use in harsh environments. Special steel, engineered with enhanced hardness and wear resistance, helps extend the lifespan of these components, reducing maintenance costs and downtime. Additionally, special steel provides superior corrosion resistance, which is vital for construction machinery used in humid or corrosive environments. By preventing rust and decay, special steel helps maintain the equipment's performance and longevity, ultimately increasing productivity and efficiency in construction projects. Furthermore, special steel enables the construction machinery industry to achieve innovative designs and advanced functionalities. Its versatility allows for the creation of complex shapes and precise tolerances, which are essential for optimizing the performance and efficiency of machinery. Special steel also enables the incorporation of advanced technologies, such as sensors and automation, enhancing the accuracy and productivity of construction equipment. In summary, special steel contributes significantly to the construction machinery industry through its ability to withstand extreme conditions, provide superior wear resistance and corrosion protection, and enable innovative designs. By utilizing special steel in the manufacturing process, construction machinery manufacturers can ensure the durability, safety, and efficiency of their equipment, ultimately benefiting the construction industry as a whole.

- Q: How does special steel contribute to the efficiency of automotive engines?

- Special steel contributes to the efficiency of automotive engines in several ways. Firstly, it provides higher strength and durability, allowing for the production of lighter components without sacrificing performance or safety. This reduces the overall weight of the engine, enhancing fuel efficiency and reducing emissions. Additionally, special steel alloys often have superior heat resistance and thermal conductivity properties, enabling engines to operate at higher temperatures without compromising their efficiency. Furthermore, special steel's exceptional wear resistance helps to extend the lifespan of engine components, minimizing maintenance and replacement needs. Overall, special steel plays a crucial role in optimizing the efficiency and performance of automotive engines.

- Q: What is the role of carbon in special steel?

- Carbon plays a crucial role in special steel as it significantly influences its properties and performance. Special steel refers to a category of steel that is specifically engineered to exhibit exceptional characteristics, such as high strength, hardness, wear resistance, or corrosion resistance. Carbon is one of the main alloying elements in special steel, and its content determines many of these desired properties. Firstly, carbon is responsible for increasing the strength and hardness of special steel. As carbon is added to the iron matrix, it forms iron carbides, which are extremely hard and provide structural integrity to the steel. The higher the carbon content, the greater the hardness and strength of the steel. This makes special steel suitable for applications requiring high toughness, durability, and resistance to deformation, such as in the manufacturing of tools, dies, and industrial machinery components. Secondly, carbon contributes to the wear resistance of special steel. The presence of carbon enhances the steel's ability to resist abrasion and withstand extreme conditions. This is particularly important in industries like mining, construction, and oil and gas, where components are subjected to intense wear and friction. Furthermore, carbon also plays a crucial role in determining the machinability and weldability of special steel. The carbon content affects the steel's response to heat treatment, making it easier or harder to machine or weld. The right balance of carbon content is essential to ensure that special steel can be easily worked on and fabricated into complex shapes without compromising its properties. Lastly, carbon influences the corrosion resistance of special steel. While steel is generally prone to corrosion, the addition of certain amounts of carbon can enhance its resistance to rusting and other forms of corrosion. This is particularly important in applications where the steel is exposed to harsh environments, such as marine or chemical industries. In summary, carbon plays a vital role in special steel by increasing its strength, hardness, wear resistance, machinability, weldability, and corrosion resistance. The precise amount of carbon added to the steel is carefully controlled to achieve the desired properties for specific applications, making special steel a highly versatile and sought-after material in various industries.

- Q: What are the different methods for surface hardening special steel?

- There are several methods for surface hardening special steel, including carburizing, nitriding, induction hardening, flame hardening, and laser hardening. Carburizing involves introducing carbon into the surface of the steel through heating in a carbon-rich environment. Nitriding involves diffusing nitrogen into the surface of the steel to create a hard nitride layer. Induction hardening uses electromagnetic induction to heat the surface of the steel and then rapidly quench it to increase hardness. Flame hardening involves heating the surface of the steel with a flame and then quenching it to harden the surface. Laser hardening uses a high-intensity laser beam to heat the surface of the steel and then quench it, resulting in a hardened surface.

- Q: What are the different defense grades of special steel?

- The different defense grades of special steel typically include grades such as AR200, AR400, AR500, and AR600, which are commonly used for protective armor and structural applications. These grades have varying levels of hardness, strength, and resistance to abrasion, making them suitable for different levels of defense against impacts, wear, and penetration.

- Q: What are the applications of high-speed steel?

- High-speed steel (HSS) finds numerous applications due to its exceptional combination of hardness, toughness, and heat resistance. It is extensively used in cutting tools, such as drills, end mills, and lathe tools, enabling efficient machining of various materials, including metals, plastics, and wood. HSS is also employed in forming tools, such as taps and dies, where it can withstand the high pressures and temperatures involved in metalworking processes. Additionally, HSS is utilized in saw blades, milling cutters, and gear cutters, enhancing their durability and performance. Its versatility and reliability make high-speed steel a crucial material in various industries, including manufacturing, automotive, aerospace, and construction.

- Q: How does special steel contribute to the shipbuilding industry?

- Special steel plays a crucial role in the shipbuilding industry by providing enhanced strength, durability, and corrosion resistance to ships. It allows for the construction of lighter and more fuel-efficient vessels without compromising on structural integrity. Additionally, special steel enables the development of advanced ship components, such as propellers, hulls, and offshore structures, which can withstand harsh marine environments and ensure safer and more reliable operations at sea.

Send your message to us

ASTM DIN JIS Standard 1020 1045 Carbon Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords