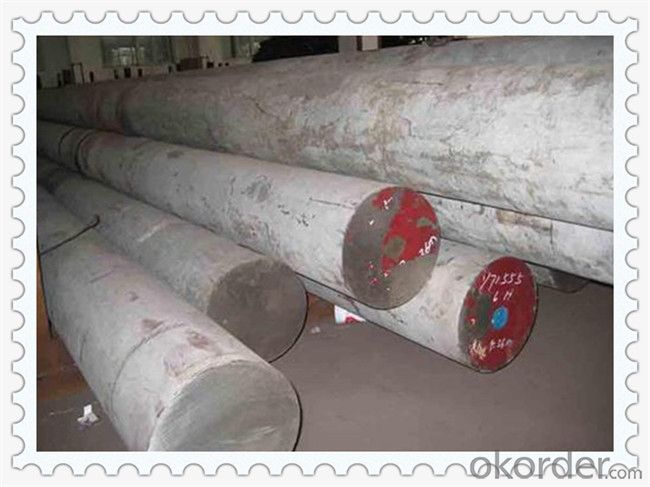

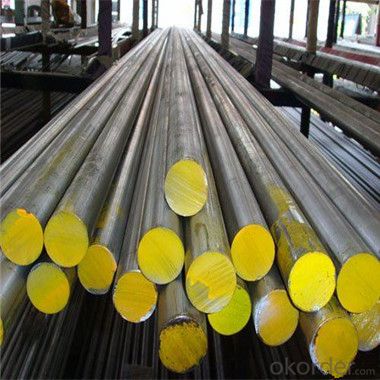

AISI 1045 Carbon Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

AISI 1045 Carbon Steel Round Bar

Standard | ASTM A29/A29M-04 | ||||||||||

Grade | 1045 | ||||||||||

MOQ | 1 Metric Ton | ||||||||||

Diameter | 12mm~1500mm | ||||||||||

Length | 6m,12m or as required. | ||||||||||

Diameter Tolerance | As required | ||||||||||

Condition of delivery | Hot rolled,Cold Rolled or as required. | ||||||||||

Chemical Composition(%) | |||||||||||

C | Si | Mn | P | S | Cr | ||||||

0.42~0.50% | 0.17~0.37% | 0.50~0.80% | ≤0.035% | ≤0.035% | ≤0.40% | ||||||

Ni | Cu | ||||||||||

≤0.035% | ≤0.25% | ||||||||||

Mechanical Properties(In Quenching and Tempering) | |||||||||||

Tensile strength | Yield strength | Elongation | Reduction in Area | Impact | Hardness | ||||||

(σb/MPa) | (σs/MPa) | (δ5/%) | (ψ/%) | (J) | (HB) | ||||||

≥ 600Mpa | ≥ 355Mpa | 16% | 40% | 39J | ≤229HB | ||||||

Packaging & Shipping

Packaging: According to customer's requirements or export standard.

Shipment: By express,mainly suitable for samples.

By air ,mainly suitable for urgent orders.

By ship ,suitable for large quantities,cheaper but a bit slower.

Our Products

Steel wire, Steel Round bar

Diameter: 0.14mm-2000mm

Steel Square bar

Size : 50mm * 50mm-600mm *600mm

Steel Plate(sheet), flat steel bar

Thickness: 0.1mm-800mm Width: 10mm to 1900mm

Cold-rolled Plate(sheet)

Thickness: 0.1-8mm Width: 1000mm

Hot-rolled Plate(sheet)

Thickness: 6-200mm Width : 210-1900mm

Surface: 2B, BA, 6K, 8K, 12K, etc.

Welded/seamless Steel Pipe(tube)

outer diameter: 6-219mm wall thickness: 1-35 mm.

Length: according to the customer's requirements.

Condition of delivery

Hot-rolling+annealing,normalizing+tempering,quenching+tempering,cold-drawn or according to the customer's requirements.

Surface: rough machining,fine machining,polishing,bright,pickling,black or according to the customers’ requirements.

Furnaces for metallurgical processing: electrode arc + LF,VD,VOD,ESR,Vacuum consumable electrode.

Ultrasonic inspection: 100% ultrasonic inspection for any in perfections or according to the customers’ requirements.

All of our steels can be customized(standard GB, ASTM, JIS, DIN, etc.)

- Q: Are steel round bars suitable for the manufacturing of shafts?

- Yes, steel round bars are suitable for the manufacturing of shafts. Steel round bars are known for their strength, durability, and ability to withstand heavy loads and high rotational speeds, making them ideal for shaft applications. The round shape of the bar promotes uniform stress distribution, reducing the risk of failure or deformation. Additionally, steel round bars can be easily machined and heat-treated to achieve desired mechanical properties, such as hardness and toughness, further enhancing their suitability for shaft manufacturing. Overall, steel round bars offer the necessary characteristics required for shafts, making them a reliable and commonly used material in various industries.

- Q: Can steel round bars be coated?

- Yes, steel round bars can be coated. Coating steel round bars provides several benefits, including improved corrosion resistance, enhanced durability, and increased aesthetic appeal. The most common types of coatings for steel round bars include galvanized coatings, epoxy coatings, and powder coatings. Galvanized coatings involve the application of a layer of zinc to the surface of the steel, which provides excellent corrosion protection. Epoxy coatings are typically used for industrial applications as they offer superior chemical resistance and can withstand harsh environments. Powder coatings involve the application of a dry powder electrostatically, which is then cured under heat to form a hard, protective layer. These coatings can be applied to steel round bars to protect them from rust and other forms of corrosion, making them suitable for a wide range of applications in various industries such as construction, manufacturing, and automotive.

- Q: Can steel round bars be used in high temperature applications?

- High temperature applications can make use of steel round bars. Yet, the steel type and composition play a pivotal role in determining their appropriateness for such circumstances. Specific steel grades, like stainless steel or heat-resistant alloys, are purposefully crafted to endure high temperatures, upholding their strength and avoiding deformation. These steel round bars find applications in furnace components, boiler tubes, and heat exchangers, where they confront intense heat. To guarantee optimal performance and longevity, it is vital to carefully choose the suitable steel grade based on the application's specific temperature demands and conditions.

- Q: What is the tolerance for length in steel round bars?

- The tolerance for length in steel round bars can vary based on specific manufacturing standards and requirements. Typically, the tolerance is defined as the maximum allowable deviation from the desired length and can be expressed as a percentage or specific measurement in millimeters or inches. Various international standards organizations, such as ASTM or ISO, may have their own guidelines for steel round bar tolerances. These standards ensure consistent and reliable measurements across the industry. In practice, tolerances for steel round bar length can range from tight tolerances of a few millimeters for precision applications to looser tolerances of several centimeters for general-purpose use. It is important to consider that the tolerance may also depend on the size and diameter of the bar. Smaller diameter bars may have tighter tolerances due to the challenges in manufacturing and accurately measuring longer lengths. Ultimately, the specific tolerance for steel round bar length should be determined based on the intended application and relevant industry standards or customer specifications.

- Q: What are the different types of steel round bar alloys used in aerospace applications?

- The different types of steel round bar alloys used in aerospace applications include stainless steel, nickel-based alloys, and titanium alloys. These alloys are chosen for their high strength-to-weight ratios, corrosion resistance, and ability to withstand extreme temperatures and pressures encountered in aerospace environments.

- Q: What are the different types of steel round bars used in the automotive braking systems?

- There are several different types of steel round bars that are commonly used in automotive braking systems. These types of steel are specifically chosen for their strength, durability, and ability to withstand the high temperatures and pressures that are generated during braking. One commonly used type of steel round bar is carbon steel. This type of steel is known for its high strength and excellent hardness. Carbon steel round bars are often used in the manufacturing of brake rotors and brake drums. They are able to withstand the friction and heat generated during braking, ensuring reliable performance and longevity. Another type of steel round bar used in automotive braking systems is stainless steel. Stainless steel is highly resistant to corrosion and rust, making it ideal for brake lines and fittings. It also has good heat resistance properties, allowing it to withstand the thermal stresses generated during braking. Some automotive braking systems also utilize alloy steel round bars. Alloy steel is a combination of different metals, such as chromium, nickel, and molybdenum, which enhance its mechanical properties. Alloy steel round bars are known for their high tensile strength and toughness, making them suitable for applications that require a high level of performance and durability. In addition to these commonly used types of steel round bars, there are also specialized types that are designed for specific applications within automotive braking systems. For example, heat-treated steel round bars are used in the manufacturing of brake calipers and pistons, as they can withstand the extreme temperatures generated by the friction between the brake pads and rotors. Overall, the choice of steel round bar in automotive braking systems depends on the specific requirements of the application, such as strength, durability, heat resistance, and corrosion resistance. By selecting the appropriate type of steel, automotive manufacturers can ensure the safety and reliability of their braking systems.

- Q: Can steel round bars be used in the production of bearings?

- No, steel round bars are not typically used in the production of bearings. Bearings are usually made from specialized materials such as stainless steel, bearing steel, or other alloys specifically designed for their load-bearing properties and ability to reduce friction.

- Q: What is the difference between a rough turned and a centerless ground steel round bar?

- A rough turned steel round bar is a steel bar that has been machined to a standard size and shape using a lathe or turning machine. This involves removing excess material from the bar's surface to achieve the desired diameter and smoothness. The resulting rough turned bar may still have minor imperfections or variations in size and surface finish. On the contrary, a centerless ground steel round bar undergoes a different manufacturing process. This process involves feeding the steel bar through two rotating wheels - a grinding wheel and a regulating wheel. The grinding wheel removes material from the bar's surface to achieve a precise diameter, while the regulating wheel controls the bar's feed rate. This process ensures precise tolerances, an excellent surface finish, and a consistent diameter along the entire length of the bar. In conclusion, the primary distinction between a rough turned and a centerless ground steel round bar lies in the manufacturing process and resulting quality. While a rough turned bar is machined to a standard size and shape with some imperfections, a centerless ground bar undergoes a more precise grinding process to achieve a highly accurate diameter, excellent surface finish, and consistent dimensions throughout the bar.

- Q: How do you calculate the fatigue strength of a steel round bar?

- Various methods can be employed to calculate the fatigue strength of a steel round bar. For instance, the stress-life (S-N) curve approach or the strain-life (ε-N) curve approach can be utilized. The stress-life (S-N) curve approach entails plotting the stress amplitude (S) against the number of cycles to failure (N) on a log-log scale. By subjecting multiple specimens of the steel round bar to different stress levels and measuring the number of cycles to failure for each stress level, the S-N curve can be obtained. The fatigue strength of the steel round bar can then be determined by identifying the stress level at which the desired number of cycles to failure is achieved, commonly known as the endurance limit. On the other hand, the strain-life (ε-N) curve approach involves plotting the strain amplitude (ε) against the number of cycles to failure (N) on a log-log scale. Similar to the S-N curve approach, multiple specimens of the steel round bar are subjected to different strain levels, and the number of cycles to failure is recorded. By utilizing the strain-life curve, the fatigue strength can be determined by identifying the strain level corresponding to the desired number of cycles to failure. It should be emphasized that calculating the fatigue strength of a steel round bar necessitates conducting fatigue tests on representative specimens under controlled conditions. These tests involve subjecting the specimens to cyclic loading, typically in the form of tension-compression cycles, and recording the number of cycles to failure. The data obtained from these tests is then utilized to construct the S-N curve or the ε-N curve, which offers valuable insights into the fatigue behavior and strength of the steel round bar.

- Q: Can steel round bars be plated?

- Yes, steel round bars can be plated. Plating is a common process used to enhance the appearance and protect the surface of steel bars. The plating can be done using various materials such as chrome, nickel, or zinc, depending on the desired outcome and application of the steel bars. Plating can provide additional corrosion resistance, improve hardness or wear resistance, and also create an attractive finish. It is important to note that proper preparation and cleaning of the steel surface before plating is crucial to ensure a durable and high-quality plated finish.

Send your message to us

AISI 1045 Carbon Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords