ASTM A569 Hot Rolled Carbon Steel Plate_Carbon Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

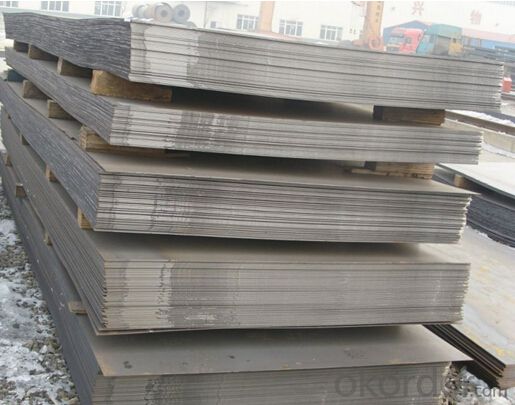

Specification of ASTM A569 Hot Rolled Carbon Steel Plate_Carbon Steel Sheet

Thickness:0.6-200mm

Width:500-4000mm

MOQ: 1 ton

Certificate:ISO,SGS

Details of ASTM A569 Hot Rolled Carbon Steel Plate_Carbon Steel Sheet

Commodity | Prime hot rolled carbon steel plate / sheet dimensions |

Thickness | 0.6-200mm |

Width | 1000-4000mm |

Length | as custom's request |

Technique | Cold rolled or hot rolled mild steel plate |

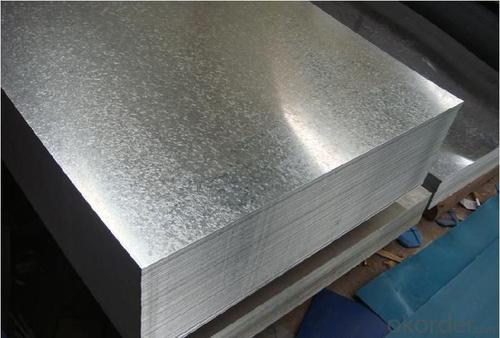

Surface treatment | Bare, galvanized coated or as customer's requirements. |

Standard | ASTM,EN,GB,JIS |

Material | A283Gr.D/A573Gr.65,A516Gr65,A516Gr70,A284Gr.D SS400,SS300,CCSB A36,A32,LRA32,LRB,Q235 SAE1010,SAE1020,SAE1045,Q195,Q235,Q345,SS400,ASTM A36,E235B |

Usage | Used in home appliances construction, machinery manufacturing, container manufacturing, shipbuilding, bridges, etc. |

Terms of Payment | 30% T/T as deposit and 70% T/T balance againest B/L copy. |

Delivery Detail | Within 3-15 days after receipt of deposited for the mild steel plate |

CNBM Introduction of ASTM A569 Hot Rolled Carbon Steel Plate_Carbon Steel Sheet

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery of ASTM A569 Hot Rolled Carbon Steel Plate_Carbon Steel Sheet

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the different heat treatment techniques used for special steel?

- There are several heat treatment techniques used for special steel, including annealing, normalizing, quenching, tempering, and case hardening. Each technique serves a specific purpose in altering the properties of the steel, such as improving hardness, strength, toughness, or ductility. Annealing involves heating the steel to a specific temperature and then slowly cooling it to relieve internal stresses and increase ductility. Normalizing is similar to annealing but involves air cooling instead of slow cooling. Quenching involves rapid cooling of the steel to increase hardness, while tempering is a subsequent heating process to reduce brittleness and enhance toughness. Case hardening involves heating the steel in the presence of a carbon-rich atmosphere to increase surface hardness while maintaining a tough core.

- Q: How does special steel contribute to the automotive racing industry?

- Special steel plays a crucial role in the automotive racing industry by providing high-performance components and ensuring the safety and reliability of race cars. Its unique properties such as strength, durability, and heat resistance make it ideal for various applications in racing vehicles. One of the main contributions of special steel to the automotive racing industry is its use in the construction of engine parts. Components like crankshafts, camshafts, connecting rods, and valves are subjected to extreme forces and temperatures during racing. Special steel alloys, such as high-strength steels, are specifically designed to withstand these conditions and offer superior performance compared to conventional steel. This allows race car engines to operate at higher speeds, generate more power, and endure intense racing conditions without compromising reliability. Furthermore, special steel is also extensively used in the manufacturing of suspension systems and chassis components. Racing cars are subjected to extreme loads and vibrations while cornering and maneuvering at high speeds. The use of high-strength steel in these critical components enhances the structural integrity of the vehicle, improving stability, handling, and overall performance. In addition to performance benefits, special steel also contributes to the safety of race cars. Safety is of paramount importance in the racing industry, and the use of special steel in roll cages and crash structures provides enhanced protection to drivers in case of accidents. Special steel alloys, such as boron steel, offer exceptional strength and energy absorption capabilities, minimizing the risk of injury during crashes. Moreover, the lightweight nature of special steel allows for the reduction of overall vehicle weight, leading to improved fuel efficiency and better handling. By using advanced steel materials and design techniques, race car manufacturers can achieve a balance between strength and weight, optimizing performance without compromising safety. In summary, special steel plays a vital role in the automotive racing industry by contributing to the performance, safety, and reliability of race cars. Its unique properties allow for the development of high-performance engine parts, suspension systems, and chassis components, enabling race cars to withstand extreme conditions and achieve superior performance on the track. Moreover, special steel enhances the safety of race cars by providing robust crash protection, while also offering weight reduction benefits for improved fuel efficiency and handling.

- Q: What are the common challenges in heat treating titanium alloys?

- There are various difficulties encountered when heat treating titanium alloys. One of the primary obstacles arises from titanium's strong tendency to react with oxygen, nitrogen, and hydrogen at elevated temperatures. This reactivity can lead to contamination on the surface and the creation of unwanted oxides, nitrides, or hydrides, which can adversely affect the mechanical characteristics of the alloy. Another challenge involves the development of alpha-case, a thick layer of alpha-phase titanium that forms on the alloy's surface during the heating process. This alpha-case is brittle and can significantly diminish the material's fatigue strength and ductility. Consequently, it is crucial to minimize or eliminate the formation of alpha-case during titanium alloy heat treatment. Moreover, titanium alloys have a limited temperature range for effective heat treatment. If the temperature is too low, the desired microstructure and mechanical properties may not be achieved. Conversely, if the temperature is too high, grain growth can occur, resulting in reduced strength and toughness of the alloy. Furthermore, precise control over the heating and cooling rates is often required when heat treating titanium alloys to achieve the desired microstructure and properties. Inadequate or uneven cooling can lead to non-uniform microstructures, residual stresses, or distortion of the component. Finally, the cost of heat treating titanium alloys can pose a challenge. Titanium alloys have a high affinity for oxygen, necessitating the use of specialized equipment such as vacuum furnaces or controlled atmosphere furnaces to maintain a low oxygen environment. These specialized heat treatment processes can be costly and demand careful handling and maintenance to ensure the desired outcomes. To summarize, the common challenges encountered in heat treating titanium alloys include managing reactivity with oxygen, nitrogen, and hydrogen, minimizing alpha-case formation, achieving the appropriate temperature range, controlling heating and cooling rates, and dealing with the expenses associated with specialized equipment and processes. Overcoming these challenges is essential to obtain high-quality titanium alloy components with the desired properties.

- Q: How does special steel contribute to the manufacturing of bearings?

- Special steel plays a crucial role in the manufacturing of bearings as it offers enhanced strength, durability, and corrosion resistance. The unique properties of special steel, such as high hardness and wear resistance, allow bearings to withstand heavy loads and operate at high speeds. Additionally, special steel alloys can be tailored to specific application requirements, ensuring optimal performance and longevity of bearings in various industries.

- Q: Can special steel be used for food processing equipment?

- Yes, special steel can be used for food processing equipment. Special steel, often referred to as stainless steel, is commonly used in the food industry due to its corrosion resistance, durability, and hygienic properties. It is non-reactive and does not leach any harmful substances into the food, making it a safe and reliable choice for various food processing applications.

- Q: How does special steel contribute to the manufacturing of precision components?

- The manufacturing of precision components heavily relies on special steel, which offers a wide range of desirable properties necessary for achieving high levels of accuracy and reliability. To begin with, special steel is renowned for its remarkable strength and durability. This enables precision components to endure the immense stress and load they may encounter during operation. By utilizing special steel, manufacturers can create precision components that can withstand intense forces without warping, deforming, or breaking, ensuring long-lasting performance and reliability. Furthermore, special steel demonstrates excellent resistance to wear. Components manufactured from special steel can endure friction, abrasion, and wear caused by continuous use or contact with other materials. This is especially crucial for precision components, as even the slightest wear or deformation can significantly impact their functionality and accuracy. By employing special steel, manufacturers can guarantee that precision components maintain their shape and integrity, resulting in superior performance and longevity. Moreover, special steel offers outstanding machinability. Its composition and properties make it easier to cut, shape, and form into complex geometries, allowing manufacturers to produce intricate precision components with tight tolerances. This improved machinability facilitates the production of components with precise dimensions, ensuring accuracy and consistency in the final product. Additionally, special steel exhibits excellent resistance to corrosion. Precision components are frequently exposed to harsh environments, chemicals, or moisture, which can lead to corrosion and degradation. However, special steel's corrosion resistance properties help prevent rusting and corrosion, ensuring that precision components remain functional and reliable throughout their lifespan. Lastly, special steel provides thermal stability and resistance to high temperatures. Precision components may come into contact with extreme heat or experience rapid temperature changes during operation. The ability of special steel to withstand these conditions without compromising its strength or dimensional stability is crucial in ensuring the performance and accuracy of precision components in demanding applications. In conclusion, special steel plays a vital role in the manufacturing of precision components by offering exceptional strength, wear resistance, machinability, corrosion resistance, and thermal stability. These properties enable manufacturers to produce precise, high-quality components that meet the stringent requirements of various industries, including aerospace, automotive, electronics, and medical devices.

- Q: How does special steel perform in terms of wear resistance?

- Special steel performs exceptionally well in terms of wear resistance. It is specifically engineered to withstand abrasive forces, making it highly durable and long-lasting even in demanding environments. The unique composition and heat treatment processes used in its production enhance its hardness, toughness, and ability to resist wear, ensuring that it can withstand friction, impact, and other forms of wear and tear with minimal degradation.

- Q: What are the main characteristics of pressure vessel steel forgings?

- Pressure vessel steel forgings possess several key features that render them suitable for utilization in pressure vessels. Firstly, these forgings are renowned for their exceptional strength and toughness. This attribute is of utmost importance as pressure vessels typically encounter significant internal pressure, necessitating steel capable of withstanding such force without deformation or rupture. Meticulous design and manufacturing ensure that the forgings possess the requisite strength and toughness to endure these pressures. Secondly, pressure vessel steel forgings exhibit remarkable resistance to corrosion. Given that pressure vessels frequently house corrosive fluids or gases, it becomes imperative for the steel employed in their construction to possess corrosion resistance. This feature guarantees the durability and dependability of the pressure vessel. The steel forgings are often crafted with specific alloying elements that enhance their resistance to corrosion. A further notable characteristic of pressure vessel steel forgings lies in their ability to retain their mechanical properties at elevated temperatures. Pressure vessels may be subjected to heightened temperatures due to the nature of the processes or fluids they contain. The forgings are designed to maintain their strength and toughness even in these high-temperature conditions, thereby ensuring the safety and reliability of the pressure vessel. Moreover, pressure vessel steel forgings typically undergo stringent quality control measures during their manufacturing process. This is essential to ensure that the forgings meet the prescribed standards and specifications for pressure vessel applications. The manufacturing process incorporates comprehensive inspections, testing, and documentation to guarantee compliance with the necessary quality and safety requirements. In summary, the primary characteristics of pressure vessel steel forgings encompass high strength and toughness, exceptional corrosion resistance, the ability to endure high temperatures, and stringent quality control measures. These attributes render pressure vessel steel forgings ideal for utilization in pressure vessels, providing the requisite strength, reliability, and safety demanded by such applications.

- Q: How is special steel used in the production of cutting inserts?

- The unique properties of special steel make it the ideal choice for producing cutting inserts. Cutting inserts are utilized in machining operations to shape and remove material from a workpiece. These inserts must possess the ability to endure high temperatures, resist wear and abrasion, and maintain their sharp cutting edges for extended periods. Commonly referred to as tool steel, special steel is specifically engineered to meet these requirements. It is an alloy that incorporates a variety of elements like chromium, tungsten, vanadium, and molybdenum, which enhance its mechanical properties. With its exceptional hardness, toughness, and resistance to high temperatures, special steel is a suitable material for cutting inserts. To further augment its properties, the special steel employed in manufacturing cutting inserts undergoes a series of processes, including heat treatment. This process involves subjecting the steel to specific temperatures and rapidly cooling it, resulting in increased strength and hardness. By undergoing heat treatment, the cutting inserts become capable of withstanding the extreme forces and temperatures encountered during machining operations. Moreover, special steel can be coated with materials like titanium nitride or diamond-like carbon to enhance its performance. These coatings contribute to the hardness, friction reduction, and overall wear resistance of the cutting inserts, ultimately extending their lifespan and improving efficiency. In conclusion, special steel is selected for the production of cutting inserts due to its remarkable hardness, toughness, high-temperature resistance, and wear resistance. These properties enable the cutting inserts to withstand the demanding conditions of machining operations and retain their sharp cutting edges for prolonged periods. As a result, material removal is carried out efficiently and precisely.

- Q: How does special steel perform in high-temperature hydrogen environments?

- Special steel is known for its excellent performance in high-temperature hydrogen environments. It exhibits superior resistance to hydrogen embrittlement, corrosion, and material degradation, making it a suitable choice for applications where exposure to high-temperature hydrogen is prevalent. The steel's unique composition and heat treatment processes enhance its mechanical properties and enable it to maintain its structural integrity even in challenging conditions. Overall, special steel demonstrates remarkable performance and reliability when subjected to high-temperature hydrogen environments.

Send your message to us

ASTM A569 Hot Rolled Carbon Steel Plate_Carbon Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords