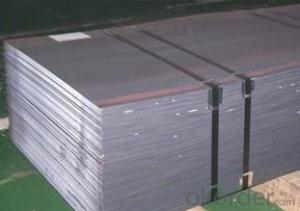

Hot Rolled Carbon Steel Plate,Carbon Steel Sheet A516Gr65 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI, ASTM, GB, JIS | Grade: | Q195,Q235,Q345,A36,C45 | Thickness: | 1.0-30MM |

| Model Number: | Q235,Q195,Q345 | ||||

| Type: | Steel Plate | Technique: | Hot Rolled | Surface Treatment: | Coated |

| Application: | Ship Plate | Special Use: | Silicon Steel | Width: | 30-2000mm |

| Length: | as your requirement | standard: | hot rolled | Surface: | Anti-rust oil |

Packaging & Delivery

| Packaging Details: | seaworthy packages or as customers' require |

| Delivery Detail: | within 15 days after the advance payment |

Hot rolled steel plate

1 carbon steel plate 3mm thick General information

| Product name | Type | Specification | Implementation of GB | ||

| thick | wide | long | |||

| Carbon structural steel | Q195,Q215, Q235A,Q235B, Q235C,Q255, Q275 | 4-120 | 1500-4500 | 6000-12000 | GB/T700-2006 |

| Low-alloy structural steel | Q295,Q345A, Q345B,Q2345C | 4-120 | 1500-4500 | 6000-12000 | BG/T1591-1994 |

| Quality carbon structural stee | 30-50 | 4-120 | 1500-4500 | 6000-12000 | BG/T699-1999 |

| Ship steel | CCSA,CCSB | 4-120 | 1500-4500 | 6000-12000 | materials and welding condition |

| CCSAH32,CCSAH36 CCSDH32,CCSDH36 | 4-120 | 1500-4500 | 6000-12000 | materials and welding condition or GB 712-2000 | |

| Boiler steel | 20g,22Mng, 16Mng,19Mng | 4-120 | 1500-4500 | 6000-12000 | GB 713-1997 |

| Pressure vessel steel | 1622Mng,20R, 15MnVR,15MnVNR | 4-120 | 1500-2700 | 6000-12000 | GB 6654-1996 |

| European standard plate

| S235JR,S235J0, S275JR,S275J0, S275JR2,S355JR, S355J0,S355J2 | 4-120 | 1500-4500 | 6000-12000 | EN 10025 |

| Japanese standard plate | SS400,SS400-B | 4-120 | 1500-4500 | 6000-12000 | JIS G3101-2004 |

2 carbon steel plate 3mm thick detail specification

Material:

A283Gr.D/A573Gr.65,A516Gr65,A516Gr70,A284Gr.D

SS400,SS300,CCSB A36,A32,LRA32,LRB,Q235

Q195,Q235,Q345,SS400,ASTM A36,E235B

Thickness: 4mm-120mm

width: 1500mm-4500mm

Length:2-10m ,accordingly

Thickness | 4-120mm |

Width | 1500-4500mm or as custom's request |

Length | 2-12m,as your requirment |

Technique | Cold rolled or hot rolled |

Surface treatment | Bare, galvanized coated or as customer's requirements. |

Standard | ASTM,EN,GB,JIS,GB |

Material | A283Gr.D/A573Gr.65,A516Gr65,A516Gr70,A284Gr.D SS400,SS300,CCSB A36,A32,LRA32,LRB,Q235 Q195,Q235,Q345,SS400,ASTM A36,E235B |

Terms of Payment | L/C or T/T |

Chemical composition | C≤0.004%;Si≤0.030%; Mn ≤0.17%;P≤0.012%; S≤0.010%; Fe balance |

Delivery Detail | within 30days once receive deposite or confirm L/C |

Packing | Standard export packing,or as requirement |

3 carbon steel plate 3mm thick application:

construction,machinery manufacturing, container manufacturing, shipbuilding, bridge construction. Can also be used to manufacture a variety of containers, the furnace shell, furnace plate, bridge and vehicle static steel plate, low alloy steel plate,shipbuilding plate, boiler plate, pressure vessel plate, pattern plate, tractor parts, automobile frame steel plate and welding components

- Q: What is the process of applying anti-fingerprint coatings to steel sheets?

- The process of applying anti-fingerprint coatings to steel sheets typically involves several steps. First, the steel sheets are thoroughly cleaned and degreased to remove any dirt or oil residue. This step is crucial to ensure proper adhesion of the coating. Next, a primer or base coat is applied to the steel sheets. This coat helps improve the bonding between the steel surface and the subsequent layers of the coating. After the base coat, the anti-fingerprint coating is applied using various methods such as spraying, dipping, or roll coating. This coating is designed to repel oils and fingerprints, making the steel sheets easier to clean and maintain. Once the coating is applied, the steel sheets are cured or dried according to the manufacturer's instructions. This step is important to ensure the coating fully adheres to the steel surface and develops its desired properties. Overall, the process of applying anti-fingerprint coatings to steel sheets involves cleaning, priming, coating, and curing to achieve a durable and effective solution for reducing fingerprints and smudges.

- Q: How do steel sheets perform in fatigue resistance?

- Steel sheets generally have excellent fatigue resistance due to their high strength and durability. They are capable of withstanding repeated loading and cyclic stresses without experiencing significant degradation in performance. The combination of their material properties and manufacturing processes allows steel sheets to effectively resist fatigue and maintain structural integrity over extended periods of time.

- Q: What are the different international standards for steel sheets?

- There are several different international standards for steel sheets, including the American Society for Testing and Materials (ASTM) standards, the International Organization for Standardization (ISO) standards, and the Japanese Industrial Standards (JIS) among others. These standards define the specifications and requirements for various characteristics of steel sheets such as dimensions, composition, mechanical properties, and surface finish.

- Q: What's the difference between profiled steel sheet and color steel plate?

- A kind of color steel plate is in fact, but now the normal pressure plate to floor plate thickness in 0.7-1.5MM is used in galvanized coil is the main steel structure building, airport, train station, subway station, shopping malls, etc. some of the large span steel structure.

- Q: Can steel sheets be used for storage tanks or containers?

- Yes, steel sheets can be used for storage tanks or containers. Steel is a durable and strong material that can withstand high pressure and is resistant to corrosion, making it suitable for storing various substances. Additionally, steel sheets can be easily shaped and welded to create custom-sized storage tanks or containers based on specific requirements.

- Q: What is the difference between color steel plate and hot galvanized sheet?

- Color coated panels, general steel and color plate enterprises demand larger, of course, automobiles and household appliances also need, but the quality requirements are higher, generally are direct orders of steel mills. Domestic color coated boards are lower, exports are full scale.

- Q: Are steel sheets prone to warping or bending?

- Yes, steel sheets are prone to warping or bending under certain conditions, such as exposure to high heat or excessive force. However, the extent of warping or bending also depends on the thickness and quality of the steel sheet.

- Q: Are steel sheets suitable for cold storage applications?

- Yes, steel sheets are suitable for cold storage applications. Steel is a durable and strong material that can withstand the low temperatures typically required for cold storage. It is resistant to corrosion and does not absorb moisture, making it ideal for keeping the cold air inside the storage area. Additionally, steel sheets can be easily cleaned and sanitized, which is important in maintaining the hygiene and safety of the stored items. Steel also provides excellent insulation properties, helping to maintain a consistent temperature within the cold storage facility. Furthermore, steel sheets can be customized and fabricated to meet the specific size and shape requirements of the cold storage application. Overall, steel sheets are a reliable and practical choice for cold storage applications.

- Q: What is the average cost of steel sheets compared to fiberglass?

- The average cost of steel sheets can vary compared to fiberglass sheets depending on a variety of factors. In general, fiberglass sheets tend to be less expensive than steel sheets. This is primarily because the raw materials used in steel sheet production are more costly, and the manufacturing process is more complex. Furthermore, steel sheets are renowned for their durability and strength, making them a popular choice for applications that require resilience and resistance to harsh weather conditions or impact. Conversely, fiberglass sheets are typically cheaper due to the lower cost of raw materials and the simpler manufacturing process involved. They are commonly employed in applications where weight and corrosion resistance are crucial factors, such as the construction of boats or aircraft. Nevertheless, it is important to acknowledge that market fluctuations, availability, and specific project requirements can also influence the cost comparison between steel and fiberglass sheets. Hence, it is advisable to obtain quotes from suppliers and compare prices to accurately determine the average cost within a given context.

- Q: Can the steel sheets be easily joined with adhesive?

- Yes, steel sheets can be easily joined with adhesive. Adhesive bonding is a commonly used method for joining steel sheets together as it offers numerous advantages. Adhesives provide a strong and durable bond between the sheets, allowing for a seamless connection. They also distribute stress evenly across the joint, reducing the likelihood of failure. In addition, adhesive bonding does not require heat or specialized equipment, making it a cost-effective and efficient solution. However, it is important to select the appropriate adhesive for the specific type of steel and surface preparation is crucial to ensure proper adhesion. Overall, when done correctly, adhesive bonding can effectively join steel sheets together.

Send your message to us

Hot Rolled Carbon Steel Plate,Carbon Steel Sheet A516Gr65 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords