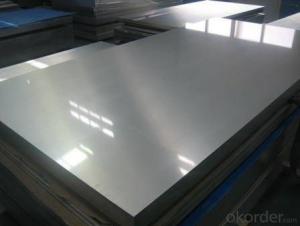

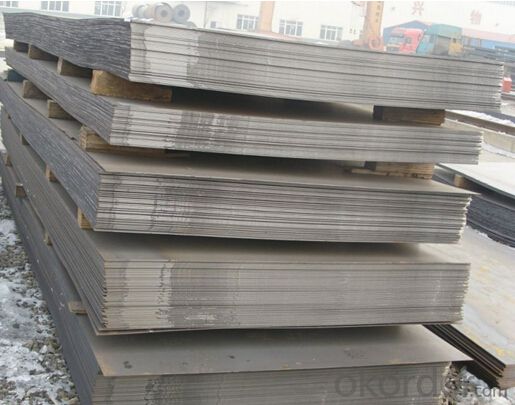

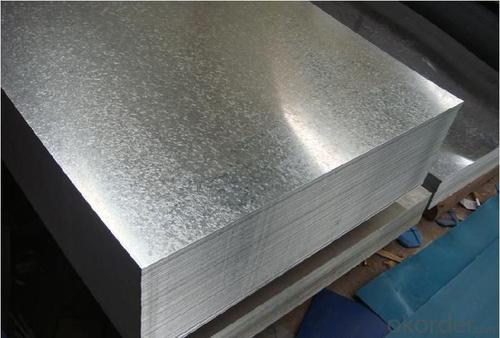

Carbon Steel Hot Rolled Coil_Plate_Strip_Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Carbon Steel Hot Rolled Coil_Plate_Strip_Sheet

Thickness:0.6-200mm

Width:1000-4000mm

MOQ: 1 ton

Certificate:ISO,SGS

Specification of Hot Rolled Coil_Plate_Strip_Sheet

Commodity | Carbon Steel Hot Rolled Coil_Plate_Strip_Sheet |

Thickness | 0.6-200mm |

Width | 1000-4000mm |

Length | as custom's request |

Technique | Cold rolled or hot rolled mild steel plate |

Surface treatment | Bare, galvanized coated or as customer's requirements. |

Standard | ASTM,EN,GB,JIS |

Material | SS330, SS400, SPHC, SPHD, SPHE, Q195, Q195L, Q235, Q345, 08AL |

Usage | 1. Automobile, Bridges, Buildings,

2. Machinery, Pressure vessel industries.

3. Ship building, Engineering construction,

4. Mechanical manufacturing, Pavement slab, ect. |

Terms of Payment | 30% T/T as deposit and 70% T/T balance againest B/L copy. |

Delivery Detail | Within 3-15 days after receipt of deposited for the mild steel plate |

CNBM Introduction of the Hot Rolled Coil_Plate_Strip_Sheet

Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery of the Hot Rolled Coil_Plate_Strip_Sheet

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: How is electrical resistance steel used in heating elements?

- Electrical resistance steel is commonly used in heating elements due to its high resistivity and ability to withstand high temperatures. When an electric current passes through the steel, its resistance generates heat, allowing the heating element to efficiently convert electrical energy into heat energy. This makes it suitable for applications such as electric stoves, water heaters, and industrial furnaces.

- Q: What are the environmental considerations of using special steel?

- Special steel production has significant environmental considerations. The extraction and processing of raw materials, such as iron and coal, contribute to deforestation, habitat destruction, and greenhouse gas emissions. Moreover, the high energy requirements during steel production result in carbon dioxide emissions, contributing to climate change. Special steel also often requires the use of alloying elements, such as chromium and nickel, which can lead to toxic waste and pollution if not properly managed. Therefore, careful monitoring and implementation of sustainable practices are crucial to minimize the environmental impact associated with using special steel.

- Q: How does special steel contribute to the pharmaceutical industry?

- Special steel plays a crucial role in the pharmaceutical industry by offering exceptional strength, corrosion resistance, and durability. It is used in the manufacturing of various equipment and components such as storage tanks, reactors, piping systems, and precision instruments. The unique properties of special steel ensure the integrity and purity of pharmaceutical products, prevent contamination, and enable efficient and safe production processes.

- Q: What are the main corrosion resistance properties of special steel?

- The main corrosion resistance properties of special steel include high resistance to rust, oxidation, and corrosion in various environments, such as acidic, alkaline, and marine conditions. Special steel is often alloyed with elements like chromium, nickel, and molybdenum, which form a protective layer on the surface and enhance its resistance to corrosion. Additionally, special steel may have a low carbon content, reducing the likelihood of corrosion caused by carbide precipitation. These properties make special steel a reliable choice for applications where resistance to corrosion is crucial, such as in the construction, automotive, and aerospace industries.

- Q: How does special steel perform in high-temperature oxidation?

- Special steel performs well in high-temperature oxidation due to its enhanced resistance to heat and corrosion. It exhibits superior strength and stability, retaining its mechanical properties even at elevated temperatures. Additionally, the presence of alloying elements like chromium, nickel, and molybdenum in special steel forms a protective oxide layer that prevents further oxidation. This makes special steel an ideal choice for applications requiring resistance to high-temperature oxidation, such as in aerospace, power generation, and chemical industries.

- Q: Can special steel be used in the jewelry industry?

- Yes, special steel can be used in the jewelry industry. It is often used as an alternative to precious metals like gold or silver due to its durability and affordability. Special steel can be used to create unique and stylish jewelry pieces, such as rings, bracelets, and necklaces, that are resistant to tarnish and wear.

- Q: How is special steel used in the medical supply chain?

- Special steel is used in the medical supply chain for a variety of applications. It is utilized in the manufacturing of surgical instruments, implantable devices, and medical equipment due to its high strength, corrosion resistance, and biocompatibility. Special steel ensures the durability and reliability of these critical medical supplies, contributing to the safety and effectiveness of healthcare procedures and treatments.

- Q: How does special steel contribute to the elasticity of products?

- Special steel contributes to the elasticity of products due to its unique composition and manufacturing process. The elasticity of a material refers to its ability to return to its original shape or size after being deformed or stretched. In the case of special steel, its specific properties enhance the elasticity of products in several ways. Firstly, special steel is often alloyed with elements such as nickel, chromium, or vanadium, which improve its mechanical properties. These alloying elements modify the crystal structure of the steel, resulting in a material that has a higher yield strength and tensile strength. This increased strength allows the steel to withstand higher levels of stress and deformation without permanent deformation or failure. Additionally, the manufacturing process of special steel involves precise control over its microstructure. Through techniques such as heat treatment and cold working, the steel's grain size and distribution are optimized. This controlled microstructure enhances the material's elasticity by promoting a uniform deformation mechanism. When a product made from special steel is subjected to external forces or stress, the steel's microstructure allows for the redistribution of these forces, minimizing localized deformation and maximizing overall elasticity. Furthermore, special steel often possesses a high carbon content, which contributes to its elasticity. The carbon atoms within the steel form strong chemical bonds with the iron atoms, resulting in a material with increased hardness and resistance to deformation. This enhanced resistance to deformation allows the steel to exhibit greater elasticity when subjected to external forces. Overall, special steel's unique composition, precise manufacturing processes, and specific alloying elements all contribute to its ability to enhance the elasticity of products. By incorporating special steel into the design and construction of various products, manufacturers can ensure that these products can withstand deformation and return to their original shape, thus increasing their durability and longevity.

- Q: How does special steel contribute to improving product sustainability?

- Special steel contributes to improving product sustainability in several ways. Firstly, it offers enhanced durability and strength, which means that products made from special steel have a longer lifespan and reduced need for frequent replacements. This reduces the overall impact on the environment by minimizing waste generation and conserving resources. Secondly, special steel often has high corrosion resistance, making it suitable for use in various industries, including construction, automotive, and aerospace. This resistance to corrosion ensures that products made from special steel require less maintenance and repairs over time, reducing the consumption of energy, materials, and resources. Additionally, special steel can be recycled and reused efficiently. This recyclability reduces the demand for new raw materials, decreases energy consumption, and minimizes greenhouse gas emissions associated with the production of steel from virgin materials. By using recycled special steel, companies can contribute to a circular economy and reduce their environmental footprint. Overall, the utilization of special steel in various products contributes to their longevity, reduced maintenance needs, and recyclability, all of which are essential for improving product sustainability and minimizing environmental impact.

- Q: How does special steel contribute to the medical field?

- Special steel plays a crucial role in the medical field by offering unique properties and characteristics that are essential for various medical applications. Firstly, special steel is widely used in the production of surgical instruments and medical devices due to its exceptional strength, durability, and corrosion resistance. These qualities ensure that the instruments can withstand the demanding environment of surgical procedures, remain sharp for extended periods, and resist the effects of sterilization processes. Additionally, special steel is utilized in the manufacturing of implants and prosthetics. Its biocompatibility and high strength-to-weight ratio make it an ideal material for creating artificial joints, spinal implants, and dental implants. Special steel's ability to integrate with the human body without causing adverse reactions or rejection is crucial for the success of these medical interventions. Moreover, special steel is employed in the production of medical equipment such as MRI machines, X-ray machines, and radiation shields. The unique magnetic properties of certain types of special steel enable the creation of powerful magnets used in MRI machines, allowing for detailed and accurate imaging of the human body. Furthermore, special steel's ability to shield against radiation makes it an essential component in radiation therapy equipment, protecting healthcare professionals and patients from harmful radiation exposure. In summary, special steel is a critical material in the medical field due to its strength, durability, corrosion resistance, biocompatibility, and unique magnetic properties. Its applications range from surgical instruments and medical devices to implants, prosthetics, and medical equipment. The contributions of special steel in the medical field are indispensable, ensuring the safety, effectiveness, and success of various medical procedures and treatments.

Send your message to us

Carbon Steel Hot Rolled Coil_Plate_Strip_Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords