ASTM A53 Mild Steel Plate/Steel Sheet in high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

ASTM A53 Mild Steel Plate/Steel Sheet in high quality

Detailed Information of ASTM A53 Mild Steel Plate/Steel Sheet in high quality

| C | Si | P | S | yield Strength MAp | Tensile strength MAp | Elongation % | ||

| A36 | 0.24 | 0.4 | 0.045 | 0.03 | 250 | 400-520 | 26 | |

| C | Si | Mn | P | S | Cu | |||

| A283 | ≤0.27 | 0.15-0.4 | ≤0.9 | ≤0.035 | ≤0.04 | ≥0.2 | ||

| Thickness: | 6mm, 8mm, 12mm, 16mm, 20mm, 25mm, 30mm, 50mm, 80mm, 100mm, 150mm, 200mm | |||||||

| Width: | 1500mm, 1800mm, 2000mm, 2200mm, 2500mm | |||||||

| Length: | 6000mm, 8000m, can cut to width and length | |||||||

| Packing Details; | according to customer‘s require or export’s standard | |||||||

| Delivery time; | 7 days for stock sizes, 20-25 days for new production sizes | |||||||

| Port: | Tianjin China | |||||||

Related Products Overviews of ASTM A53 Mild Steel Plate/Steel Sheet in high quality

Product Name | Typical Grades | Diameter(mm) | Standard Adopted |

Carbon Steel | 20 (1020/S20C/C22) |

Ø16-Ø300 |

GB/SAE/ JIS/DIN |

40 (1040/S40C/C40) | |||

45 (1045/S45C/C45) | |||

Bearing Steel | GCr9 (51100/SUJ1) |

Ø12-Ø250 | |

GCr15 (52100/SUJ2/100Gr6) | |||

GCr9SiMn (A485-Gr.1/SUJ3) | |||

Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) |

Ø12-Ø250 | |

40Cr (5140/SCr440/41Cr4) | |||

42CrMo(4140/SCM440/42CrMo4) | |||

Gear Steel | 20CrNiMo |

Ø16-Ø600 | |

20CrMn(5115/SMnC420/20MnCr5) | |||

20CrNiMo(8620/SNCM220/20CrMiMo2) |

Related Products Application of ASTM A53 Mild Steel Plate/Steel Sheet in high quality

Carbon Steel | l Mold bottom l Plastic mold l Construction machinery parts l Automobile parts l Security grills l Screens l Construction |

Bearing Steel | l Aerospace l Navigation l Nuclear energy l Chemical industry l Electronic information l Petrochemical l Instrument and meter l Transportation |

Cr-Mo Steel | l Mechanism & Fasteners gear l Stressed components for vehicles l Engines and machines l Parts of larger cross-section |

Gear Steel | l All kinds of gears l Statically and dynamically stressed component for vehicles l Engines and machine l Larger cross-section parts l Crankshafts |

Company Introduction of ASTM A53 Mild Steel Plate/Steel Sheet in high quality

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service | l CNBM provides the services and support you need for every step of our cooperation. We’re the business partners you can trust; you can relax and get on with doing business. l For any problem, please kindly contact us at any your convenient time, we’ll reply you in our first priority within 24 hours

|

Advantages

| l Industry experience over 20 years. l Shipment of goods -More than 70 countries worldwide. l The most convenient transport and prompt delivery. l Competitive price with best service. l High technical production line with top quality products. l High reputation based on best quality products.

|

Packaging & Delivery of ASTM A53 Mild Steel Plate/Steel Sheet in high quality

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

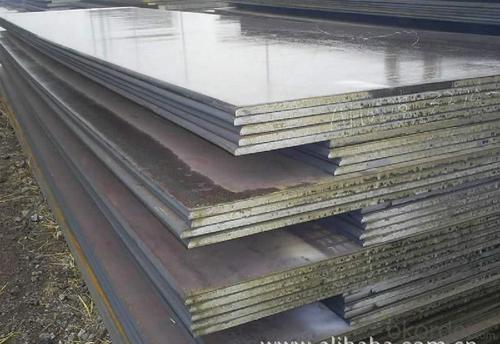

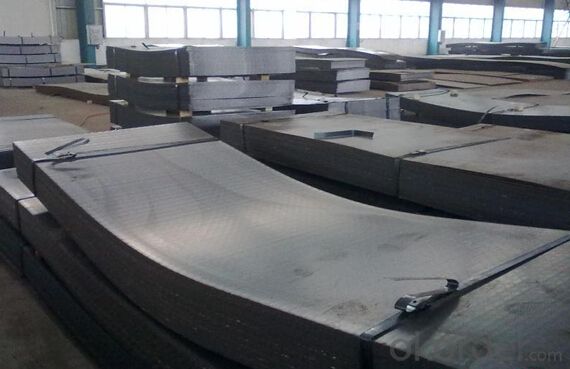

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: How does special steel contribute to the automotive exhaust system industry?

- The automotive exhaust system industry greatly benefits from the use of special steel, which makes significant contributions. Firstly, special steel, such as stainless steel, offers excellent resistance to corrosion, a common problem faced by exhaust systems due to exposure to high temperatures and corrosive gases. This corrosion resistance ensures the longevity and durability of the exhaust system, reducing the need for frequent replacements and repairs. Additionally, special steel possesses outstanding heat resistance properties. As the exhaust system operates under extreme temperatures, special steel can withstand these conditions without deforming or suffering structural damage. This ability to handle high temperatures ensures the efficient functioning and long-term performance of the exhaust system. Moreover, special steel provides exceptional strength and durability. The exhaust system is constantly subjected to vibrations, impacts, and stress due to road conditions and engine movements. The high strength and toughness of special steel enable the exhaust system to withstand these forces, preventing premature failures and ensuring the safety and reliability of the vehicle. Furthermore, special steel allows for the design and production of intricate and lightweight components for the exhaust system. With advancements in steel technology, manufacturers can create complex shapes and thin-walled structures, reducing the overall weight of the exhaust system. This weight reduction contributes to improved fuel efficiency and vehicle performance by reducing the burden on the engine. Lastly, special steel offers the automotive industry the flexibility to meet increasingly strict emission regulations. By incorporating special steel in the exhaust system, manufacturers can effectively integrate catalytic converters and other emission control devices. These devices play a crucial role in reducing harmful emissions like carbon monoxide, nitrogen oxides, and particulate matter, thus ensuring compliance with environmental standards. In conclusion, special steel is an indispensable element in the automotive exhaust system industry. Its corrosion resistance, heat resistance, strength, and lightweight properties contribute to the longevity, reliability, and performance of the exhaust system. Additionally, special steel enables compliance with emission regulations, making vehicles more environmentally friendly. Ultimately, special steel plays a vital role in improving the efficiency and sustainability of the automotive exhaust system industry.

- Q: What are the different methods of preventing pitting corrosion in special steel?

- There are several methods to prevent pitting corrosion in special steel. One common approach is the use of corrosion-resistant alloys, such as stainless steel, which contain elements like chromium and nickel that form a protective oxide layer on the surface. Additionally, applying coatings or paints can provide a barrier against corrosive agents. Another effective method is cathodic protection, where a sacrificial anode or impressed current system is employed to protect the steel from corrosion. Regular inspection and maintenance, as well as controlling the environment by reducing exposure to corrosive substances, also play crucial roles in preventing pitting corrosion in special steel.

- Q: How does special steel perform in cryogenic creep resistance?

- Special steel is renowned for its outstanding capability to resist cryogenic creep. Cryogenic creep refers to the deformation that materials undergo under constant stress in extremely low temperatures. Unlike other materials, special steel demonstrates superior resistance to this type of deformation, thanks to its distinct composition and manufacturing processes. The frigid environment encountered in cryogenic applications can weaken conventional materials and render them more susceptible to creep deformation. Nevertheless, special steel is purposefully designed to withstand these demanding conditions. Its composition typically contains a higher proportion of alloying elements, such as nickel, chromium, and molybdenum, which enhance its mechanical properties and bolster its resistance to cryogenic creep. Additionally, special steel undergoes meticulous heat treatment and processing techniques to optimize its microstructure and fortify its grain boundaries. Consequently, the resulting material possesses improved strength, toughness, and resistance to creep deformation, even at extremely low temperatures. The exceptional performance of special steel in cryogenic creep resistance renders it highly suitable for applications involving the storage, transportation, or processing of materials at cryogenic temperatures. Industries such as aerospace, energy, and scientific research heavily rely on special steel to construct cryogenic storage tanks, superconducting magnets, cryogenic valves, and more. To conclude, special steel's remarkable performance in resisting cryogenic creep can be attributed to its unique composition, heat treatment, and processing techniques. Its ability to maintain its mechanical properties and withstand deformation at extremely low temperatures makes it an ideal choice for various cryogenic applications.

- Q: How does special steel maintain its strength at different temperatures?

- Special steel maintains its strength at different temperatures due to its unique composition and heat treatment process. It is alloyed with elements like chromium, nickel, and molybdenum, which form stable compounds at high temperatures, preventing the steel from losing its strength. The heat treatment process involves carefully controlling the cooling rate, which further enhances the steel's microstructure and ensures its strength is retained even at extreme temperatures.

- Q: What are the different corrosion protection methods used for special steel?

- To ensure the durability and longevity of special steel, various methods are employed for corrosion protection. These methods encompass: 1. Coatings: The application of diverse coatings, including paint, epoxy, or zinc, creates a protective layer on the steel surface. Such coatings function as barriers, preventing direct contact between moisture, corrosive elements, and the steel. 2. Galvanization: By coating the steel with a layer of zinc through the process of galvanization, a sacrificial barrier is formed wherein the zinc corrodes instead of the steel. Galvanized steel is commonly utilized in outdoor applications such as fences, poles, and roofing. 3. Stainless steel: Special steel can be manufactured using stainless steel, which contains a high percentage of chromium. The presence of chromium results in the formation of a passive layer on the steel's surface, endowing it with excellent corrosion resistance. Stainless steel finds wide usage in industries like construction, food processing, and medical equipment. 4. Cathodic protection: This method involves the creation of an electrical current or the utilization of sacrificial anodes to protect the steel. By introducing a more reactive metal (sacrificial anode) or applying an electrical current, corrosion is minimized as the reactive metal corrodes instead of the steel. 5. Alloying: Modifying the steel's composition by incorporating elements like nickel, molybdenum, or copper can enhance its resistance to corrosion. These alloying elements form a protective layer on the surface, rendering the steel more resistant to rust and other forms of corrosion. 6. Passivation: Passivation is a chemical process that eliminates free iron from the steel's surface, leading to the formation of a protective oxide layer. This layer acts as a barrier against corrosion, augmenting the steel's resistance to rust and other forms of corrosion. 7. Proper maintenance: Regular inspection, cleaning, and maintenance of special steel play a vital role in preventing corrosion. The removal of dirt, debris, and other contaminants from the steel's surface aids in preserving its protective coatings and averting corrosion. It is crucial to select the appropriate corrosion protection method based on the specific application and environmental conditions to ensure the long-term performance and durability of special steel.

- Q: How does special steel contribute to sustainability efforts?

- Special steel contributes to sustainability efforts in several ways. Firstly, special steel is known for its durability and longevity. It has a high resistance to corrosion, wear, and tear, which means it can withstand harsh environments and heavy usage. This durability extends the lifespan of products made with special steel, reducing the need for frequent replacements. By minimizing the consumption of resources and reducing waste generation, special steel helps conserve natural resources and minimize environmental impact. Additionally, special steel is highly recyclable. It can be melted down and reprocessed multiple times without losing its properties or quality. This makes it a valuable material in the circular economy, where resources are reused and recycled to reduce dependence on virgin materials. The recycling process for special steel requires less energy compared to producing steel from raw materials, resulting in lower greenhouse gas emissions and energy consumption. Furthermore, special steel is often used in energy-efficient applications. For example, it is used in the production of wind turbines, which generate renewable energy. By providing a material that can withstand the demanding conditions of wind turbines, special steel contributes to the expansion of clean energy sources. This helps reduce reliance on fossil fuels, decrease carbon emissions, and mitigate climate change. Lastly, special steel plays a crucial role in the transportation sector. It is used in the manufacturing of lightweight, fuel-efficient vehicles, such as electric cars. By reducing the weight of vehicles, special steel helps improve fuel efficiency and decrease greenhouse gas emissions. Additionally, special steel is used in the construction of infrastructure for electric vehicle charging stations, supporting the transition to cleaner transportation systems. In conclusion, special steel contributes to sustainability efforts by promoting durability, recyclability, energy efficiency, and clean energy generation. Its properties and applications help conserve resources, reduce waste, and mitigate climate change, making it an important material in creating a more sustainable future.

- Q: How does special steel comply with international standards?

- Special steel is a type of steel that is specifically designed and manufactured to possess exceptional properties and performance characteristics. When it comes to complying with international standards, special steel undergoes a rigorous process to ensure its quality and adherence to the established norms. Firstly, special steel production adheres to international standards through the selection of raw materials. The composition and quality of the raw materials used in the manufacturing process are carefully controlled and tested to meet the specifications outlined by international standards organizations. This ensures that the special steel produced is of the desired quality and possesses the required mechanical properties. Secondly, special steel manufacturers follow standardized production processes. These processes are designed in accordance with international guidelines and standards to guarantee consistency and traceability. Through the use of advanced technologies and quality control measures, special steel manufacturers can monitor and control every stage of production, from melting and casting to rolling and heat treatment. This ensures that the final product meets the required standards in terms of chemical composition, mechanical properties, and dimensional tolerances. Furthermore, special steel undergoes stringent testing and inspection procedures to validate its compliance with international standards. This includes various destructive and non-destructive testing methods such as ultrasonic testing, hardness testing, and microstructure analysis. These tests are conducted by certified laboratories and independent third-party agencies to ensure unbiased and accurate results. In addition, special steel manufacturers often have their production processes and quality management systems audited and certified by recognized bodies, such as ISO (International Organization for Standardization), to demonstrate their commitment to compliance with international standards. It is also worth mentioning that special steel manufacturers actively participate in international standardization committees, such as ASTM International and the International Organization for Standardization (ISO). By engaging in these committees, they can contribute to the development and revision of international standards, ensuring that their products remain up to date and in line with the latest industry requirements. In conclusion, special steel complies with international standards through careful selection of raw materials, adherence to standardized production processes, rigorous testing and inspection procedures, and active participation in international standardization committees. By following these measures, special steel manufacturers demonstrate their commitment to producing high-quality products that meet the stringent requirements of international standards.

- Q: How does special steel perform in tooling applications?

- Special steel performs exceptionally well in tooling applications due to its unique properties and characteristics. Special steel, also known as tool steel, is specifically designed and manufactured to withstand the demanding conditions of tooling applications. One key advantage of special steel is its high hardness. Tooling applications often involve cutting, shaping, and forming hard materials, and special steel's hardness allows it to effectively withstand the extreme pressures and forces involved in these processes. This hardness also helps in retaining the sharpness of the cutting edges for extended periods, ensuring consistent and precise performance. Furthermore, special steel exhibits excellent wear resistance. Tooling applications typically involve repetitive and abrasive actions, which can cause considerable wear and tear on the tools. However, special steel's resistance to wear ensures that the tools maintain their performance and longevity, reducing the need for frequent replacements and downtime. Another important aspect of special steel is its excellent toughness. Tooling applications often subject the tools to sudden impacts and shock loads. Special steel's toughness enables it to absorb these impacts without fracturing or breaking, making it highly reliable and durable in such applications. Additionally, special steel offers good heat resistance and dimensional stability. Tooling applications often involve high temperatures, and special steel's ability to withstand heat prevents it from losing its hardness and other mechanical properties. This ensures consistent performance and dimensional stability, resulting in accurate and precise tooling. Lastly, special steel is also known for its corrosion resistance. Tooling applications may involve exposure to moisture, chemicals, or harsh environments, which can lead to corrosion and degradation of the tools. Special steel's corrosion resistance protects the tools from these corrosive elements, prolonging their lifespan and maintaining their performance. In conclusion, special steel is highly effective in tooling applications due to its hardness, wear resistance, toughness, heat resistance, dimensional stability, and corrosion resistance. These properties allow special steel tools to withstand the demanding conditions of tooling applications, ensuring reliable and long-lasting performance.

- Q: What are the requirements for special steel used in metalworking tools?

- Special steels used in metalworking tools require specific characteristics and qualities to ensure their effectiveness and durability in demanding applications. Some of the key requirements for special steel used in metalworking tools include: 1. High hardness: Special steels used in metalworking tools need to have a high hardness level to resist wear and deformation. This allows the tools to maintain their sharpness and cutting edge for extended periods, resulting in efficient and precise machining operations. 2. Excellent toughness: Metalworking tools are subjected to high impact and stress loads. Therefore, special steels used in these tools must possess excellent toughness to withstand the forces encountered during cutting, drilling, or shaping operations. This toughness prevents the tool from fracturing or chipping, ensuring a longer tool life. 3. Good heat resistance: Metalworking processes generate significant heat due to friction, which can compromise the performance of the tool. Special steels used in metalworking tools should exhibit good heat resistance to minimize the risk of thermal damage, such as softening or loss of hardness, even at elevated temperatures. 4. Wear resistance: The ability to resist wear is crucial for metalworking tools as they are constantly in contact with the workpiece. Special steels used in these tools should have high wear resistance to maintain their cutting performance and dimensional accuracy over time. 5. Corrosion resistance: Metalworking tools are often exposed to harsh environments, including coolants, lubricants, and corrosive elements. Therefore, special steels used in metalworking tools should possess good corrosion resistance to prevent rusting and degradation, ensuring the longevity and reliability of the tools. 6. High dimensional stability: Special steels used in metalworking tools must exhibit high dimensional stability to ensure consistent performance. This stability allows the tools to maintain their shape and size under varying operating conditions, resulting in accurate and repeatable machining processes. 7. Machinability: Special steels used in metalworking tools should be machinable, meaning they can be easily processed and shaped into the desired tool design. This characteristic allows for cost-effective manufacturing, reducing production time and expenses. Meeting these requirements ensures that special steel used in metalworking tools is capable of withstanding the demanding conditions encountered in various metal fabrication and machining operations, providing efficient cutting, shaping, and drilling capabilities while maintaining longevity and performance.

- Q: Can special steel be used in the manufacturing of precision instruments?

- Indeed, precision instruments can benefit from the utilization of special steel. Special steel encompasses a range of steel types that have been purposefully crafted and processed to possess specific attributes, such as heightened strength, hardness, resistance to corrosion, and thermal stability. These unique qualities render special steel highly suitable for applications necessitating precision and accuracy, such as precision instrument manufacturing. Precision instruments, such as surgical tools, measuring devices, optical instruments, and scientific equipment, necessitate materials capable of retaining dimensional stability and enduring extreme conditions. Special steels, such as stainless steel, tool steel, and high-speed steel, provide exceptional mechanical properties, including remarkable tensile strength, resistance to wear, and dimensional stability. Consequently, these kinds of steel are well-suited for the production of precision instruments. Moreover, special steel can be engineered to possess specific characteristics, such as low magnetic permeability or excellent resistance to temperature fluctuations. These attributes prove particularly vital in precision instruments, as magnetic interference or temperature variations have the potential to impact their performance. To summarize, special steel can indeed be employed in the manufacturing of precision instruments due to its exceptional mechanical properties, dimensional stability, and ability to withstand harsh conditions. Its versatility enables the production of precision instruments of superior quality, fulfilling the stringent requirements of various industries, including the medical, scientific, and engineering sectors.

Send your message to us

ASTM A53 Mild Steel Plate/Steel Sheet in high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords