ASTM A36 Hot Rolled Mild Steel Plate Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

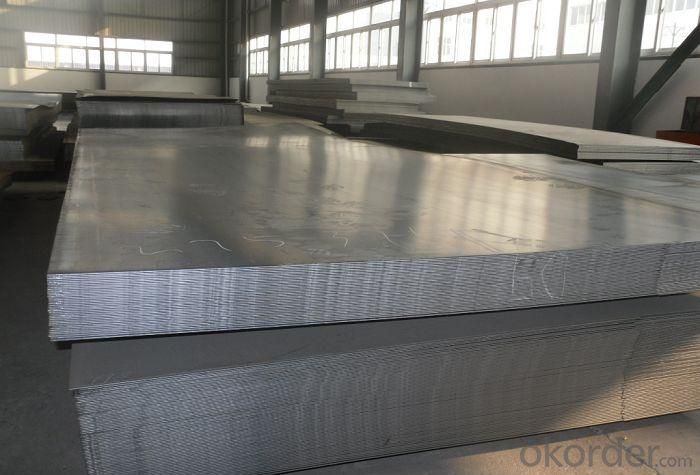

ASTM A36 Hot Rolled Mild Steel Plate Sheet

Detailed Information of ASTM A36 Hot Rolled Mild Steel Plate Sheet

| C | Si | P | S | yield Strength MAp | Tensile strength MAp | Elongation % | ||

| A36 | 0.24 | 0.4 | 0.045 | 0.03 | 250 | 400-520 | 26 | |

| C | Si | Mn | P | S | Cu | |||

| A283 | ≤0.27 | 0.15-0.4 | ≤0.9 | ≤0.035 | ≤0.04 | ≥0.2 | ||

| Thickness: | 6mm, 8mm, 12mm, 16mm, 20mm, 25mm, 30mm, 50mm, 80mm, 100mm, 150mm, 200mm | |||||||

| Width: | 1500mm, 1800mm, 2000mm, 2200mm, 2500mm | |||||||

| Length: | 6000mm, 8000m, can cut to width and length | |||||||

| Packing Details; | according to customer‘s require or export’s standard | |||||||

| Delivery time; | 7 days for stock sizes, 20-25 days for new production sizes | |||||||

| Port: | Tianjin China | |||||||

Related Products Overviews of ASTM A36 Hot Rolled Mild Steel Plate Sheet

Product Name | Typical Grades | Diameter(mm) | Standard Adopted |

Carbon Steel | 20 (1020/S20C/C22) |

Ø16-Ø300 |

GB/SAE/ JIS/DIN |

40 (1040/S40C/C40) | |||

45 (1045/S45C/C45) | |||

Bearing Steel | GCr9 (51100/SUJ1) |

Ø12-Ø250 | |

GCr15 (52100/SUJ2/100Gr6) | |||

GCr9SiMn (A485-Gr.1/SUJ3) | |||

Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) |

Ø12-Ø250 | |

40Cr (5140/SCr440/41Cr4) | |||

42CrMo(4140/SCM440/42CrMo4) | |||

Gear Steel | 20CrNiMo |

Ø16-Ø600 | |

20CrMn(5115/SMnC420/20MnCr5) | |||

20CrNiMo(8620/SNCM220/20CrMiMo2) |

Related Products Application of ASTM A36 Hot Rolled Mild Steel Plate Sheet

Carbon Steel | l Mold bottom l Plastic mold l Construction machinery parts l Automobile parts l Security grills l Screens l Construction |

Bearing Steel | l Aerospace l Navigation l Nuclear energy l Chemical industry l Electronic information l Petrochemical l Instrument and meter l Transportation |

Cr-Mo Steel | l Mechanism & Fasteners gear l Stressed components for vehicles l Engines and machines l Parts of larger cross-section |

Gear Steel | l All kinds of gears l Statically and dynamically stressed component for vehicles l Engines and machine l Larger cross-section parts l Crankshafts |

Company Introduction of ASTM A36 Hot Rolled Mild Steel Plate Sheet

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service | l CNBM provides the services and support you need for every step of our cooperation. We’re the business partners you can trust; you can relax and get on with doing business. l For any problem, please kindly contact us at any your convenient time, we’ll reply you in our first priority within 24 hours

|

Advantages

| l Industry experience over 20 years. l Shipment of goods -More than 70 countries worldwide. l The most convenient transport and prompt delivery. l Competitive price with best service. l High technical production line with top quality products. l High reputation based on best quality products.

|

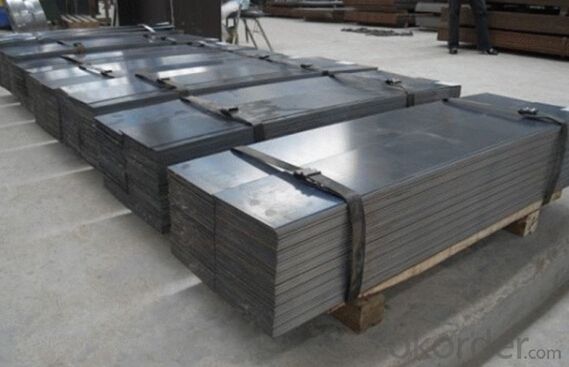

Packaging & Delivery of ASTM A36 Hot Rolled Mild Steel Plate Sheet

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the main applications of special steel in the energy storage industry?

- Special steel is extensively used in the energy storage industry for various applications. It is primarily employed in the manufacturing of storage tanks and containers, ensuring the safe storage and transport of energy sources such as liquefied natural gas (LNG) or compressed hydrogen. Special steel is also utilized in the construction of battery casings and components, providing durability and protection for energy storage systems. Additionally, special steel is crucial in the fabrication of critical infrastructure, such as pipelines and transmission towers, which play a vital role in the efficient distribution of energy. Overall, special steel serves as a fundamental material in the energy storage industry, enabling the reliable and secure storage, transportation, and utilization of various energy sources.

- Q: How is silicon steel used in electrical transformers?

- Silicon steel is used in electrical transformers as it possesses high magnetic permeability and low electrical conductivity, making it an ideal choice for the core material. The silicon content in the steel increases its resistivity and reduces the energy losses caused by eddy currents. This allows for efficient energy transfer and minimizes heat generation within the transformer.

- Q: What are the different joining methods used for special steel?

- The different joining methods used for special steel include welding, soldering, brazing, and mechanical fastening. Welding involves melting the base metal and adding a filler material to create a strong bond. Soldering and brazing use lower temperatures to join the steel using a filler material with a lower melting point. Mechanical fastening methods include bolts, nuts, screws, and rivets, which provide a secure connection without altering the base metal's properties.

- Q: What are the machining techniques for special steel?

- Some of the machining techniques commonly used for special steel include milling, turning, drilling, grinding, and broaching. These techniques are employed to shape and finish the special steel material according to the desired specifications and requirements. Additionally, special attention is given to selecting appropriate cutting tools, speeds, and feeds to ensure efficient and precise machining.

- Q: What are the different medical grades of special steel?

- Special steels used in the medical field are typically classified into different grades based on their unique properties and characteristics. These grades are specifically designed to meet the stringent requirements of medical applications, such as surgical instruments, implants, and medical devices. Some of the commonly known medical grades of special steel include: 1. Stainless Steel: Stainless steel is the most widely used medical grade of special steel due to its excellent corrosion resistance and biocompatibility. It contains high amounts of chromium and nickel, which provide resistance against corrosion and make it suitable for use in implants and surgical instruments. 2. Titanium Alloys: Titanium alloys are lightweight yet strong, making them ideal for medical applications such as orthopedic implants, dental implants, and cardiovascular devices. These alloys exhibit high biocompatibility and have excellent resistance to corrosion and fatigue, ensuring long-term durability. 3. Cobalt-Chromium Alloys: Cobalt-chromium alloys possess exceptional strength, wear resistance, and high-temperature stability, making them suitable for implantable devices like hip and knee replacements. They have excellent biocompatibility and offer a good balance between strength and flexibility. 4. Nitinol: Nitinol is a shape memory alloy composed of nickel and titanium. It displays unique properties, such as superelasticity and shape memory effect. Nitinol is commonly used in medical devices like stents, orthodontic wires, and vascular closure devices due to its excellent biocompatibility and ability to adapt to various physiological conditions. 5. High Carbon Stainless Steel: High carbon stainless steel is a specialized grade used in surgical instruments that require exceptional sharpness, hardness, and wear resistance. This grade allows for the production of extremely fine and precise cutting edges, making it suitable for delicate procedures. These are just a few examples of the medical grades of special steel used in the healthcare industry. Each grade offers specific advantages depending on the intended application, and their selection is crucial to ensure optimal performance, biocompatibility, and patient safety.

- Q: What are the different welding methods used for special steel?

- There exists a range of welding methods that can be utilized for special steel, contingent upon the specific needs of the project. Some of the commonly employed welding methods for special steel comprise the following: 1. Gas Metal Arc Welding (GMAW): Also known as MIG welding, this technique employs a consumable electrode and a shielding gas to safeguard the weld against atmospheric contamination. GMAW is advantageous for welding special steel due to its ability to produce high-quality welds with minimal spatter. 2. Gas Tungsten Arc Welding (GTAW): Also known as TIG welding, this method employs a non-consumable tungsten electrode and a shielding gas to protect the weld. GTAW is frequently employed for special steel as it allows for precise control during the welding process, resulting in defect-free, high-quality welds. 3. Shielded Metal Arc Welding (SMAW): Also known as stick welding, this technique utilizes a consumable electrode coated in flux to shield the weld. SMAW is widely employed for special steel due to its versatility and portability, making it suitable for various positions and environments. 4. Flux-cored Arc Welding (FCAW): This method employs a tubular electrode filled with flux to safeguard the weld. FCAW is often utilized for special steel due to its ability to achieve high deposition rates and deep penetration, making it suitable for thicker materials. 5. Submerged Arc Welding (SAW): This technique employs a continuously fed wire electrode and a granular flux applied around the weld. SAW is commonly used for special steel as it can produce high-quality welds in thick sections. It is crucial to consider various factors, such as the type and thickness of the steel, the desired weld quality, and the specific application requirements, when selecting the appropriate welding method for special steel. Therefore, it is advisable to consult with welding professionals or engineers to determine the most suitable method for a particular project involving special steel.

- Q: How does special steel perform in terms of machinability?

- Special steel typically performs well in terms of machinability. It is specially designed to have improved cutting, drilling, and shaping properties, making it easier to work with using various machining processes. Special steel often has a more consistent composition and structure, which results in reduced tool wear, better surface finish, and increased productivity during machining operations.

- Q: Can special steel be used in the wood manufacturing industry?

- Yes, special steel can be used in the wood manufacturing industry. Special steel, such as high-speed steel or tool steel, is often used in the production of cutting tools like saw blades or drill bits, which are essential in wood processing. These types of steel offer superior hardness, durability, and resistance to wear, allowing for efficient and precise cutting of wood. Additionally, special steel can also be used in the production of machinery or equipment used in wood manufacturing processes, providing strength and reliability.

- Q: What are the different methods of analyzing the microstructure of special steel?

- The microstructure of special steel can be analyzed using various methods. These methods involve examining and characterizing the steel at a microscopic level to gain insights into its composition, grain structure, and other features. Some commonly used methods include: 1. Optical Microscopy: By using light microscopy, the microstructure of special steel can be observed. This method allows for the identification of different phases, grain boundaries, inclusions, and other features. It provides valuable information about the size, distribution, and morphology of constituents in the steel. 2. Scanning Electron Microscopy (SEM): SEM is a powerful technique that utilizes a high-energy electron beam to analyze the microstructure of special steel. It offers detailed information about the steel's surface topography, morphology, and elemental composition. SEM is particularly useful for studying precipitates, segregation, and other microstructural defects. 3. Transmission Electron Microscopy (TEM): TEM is an advanced technique that enables analysis of the microstructure at a higher resolution compared to optical and SEM methods. It involves the transmission of electrons through a thin sample, providing information about the crystal structure, dislocations, and other fine details of the microstructure. TEM is especially beneficial for studying nanostructures and interfaces in special steel. 4. X-ray Diffraction (XRD): XRD is a non-destructive method that utilizes X-rays to analyze the crystal structure and identify phases in special steel. It provides information about the crystallographic orientation, grain size, and phase composition of the steel. XRD is widely used for analyzing phase transformations and residual stress in special steel. 5. Electron Backscatter Diffraction (EBSD): EBSD combines SEM with crystallographic analysis to provide information about the crystal orientation, texture, and grain boundaries in special steel. It is useful for studying deformation mechanisms, recrystallization, and grain growth in the steel. 6. Energy Dispersive X-ray Spectroscopy (EDS): EDS is often used in conjunction with SEM or TEM to analyze the elemental composition of special steel. It provides information about the presence and distribution of different chemical elements in the microstructure, aiding in the identification of phases and characterization of inclusions. These methods, among others, offer valuable insights into the microstructure of special steel. They enable researchers and engineers to understand the steel's properties, performance, and potential applications.

- Q: How is special steel used in the medical manufacturing process?

- Special steel is used in the medical manufacturing process for various applications such as surgical instruments, orthopedic implants, and medical devices due to its exceptional properties such as corrosion resistance, biocompatibility, and strength. It is specifically designed and manufactured to meet the stringent requirements of the medical industry, ensuring the safety and effectiveness of healthcare products.

Send your message to us

ASTM A36 Hot Rolled Mild Steel Plate Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords