ASTM A480 Jis Sus 409 Stainless Steel Plate Pheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Details | |

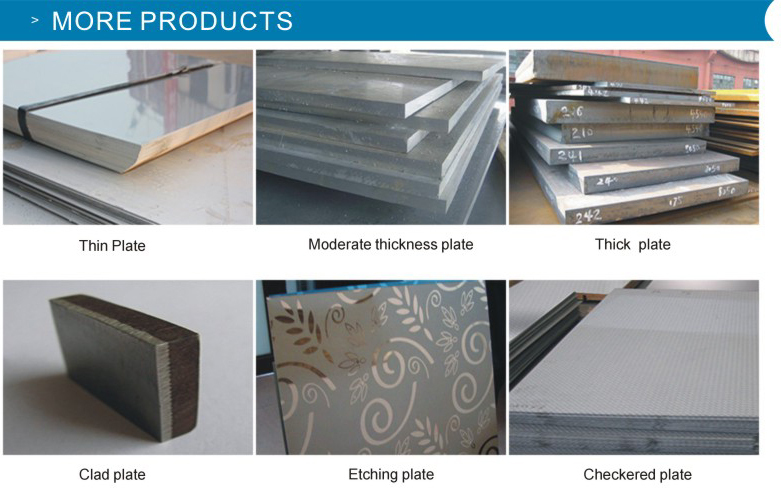

Product name | Stainless steel sheet |

Brand name | TISCO |

Standard | ASTM A240, ASTM A480, EN10088, JIS G4305 |

Material | 304, 316L, 321, 310S, 1.4301, 1.4307, 1.4404, S31803, S32750, 904L, Monel 400, Inconel 800 |

Surface | NO.1,2B,NO.4,BA,SB,Satin,Brushed,Hairline,Mirror |

Payment terms | T/T L/C WESTERN UNION |

Packing | In wooden cases,in wooden pallets |

Shipment | By sea, by air, by express |

Specifications |

Chemical Composition(%) | |||||||||||

Grade | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu | |

201 | ≤0.15 | ≤0.75 | 5.5~7.5 | ≤0.060 | ≤0.03 | 16.00~18.00 | 3.5~5.5 | - | - | 0.08 | 1.5 |

| 202 | ≤0.15 | ≤1.00 | 7.5~10.00 | ≤0.060 | ≤0.03 | 17.00~19.00 | 4.0~6.0 | - | ≤0.25 | ||

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 6.00~8.00 | - | |||

| 302 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 17.00~19.00 | 8.00~10.00 | - | |||

| 304 | ≤0.07 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 8.00~10.50 | - | |||

| 304L | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 9.00~13.00 | - | |||

| 310S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 24.00~26.00 | 19.00~22.00 | - | |||

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 10.00~14.00 | 2.00~3.00 | |||

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 12.00~15.00 | 2.00~3.00 | |||

| 321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 17.00~19.00 | 9.00~13.00 | - | |||

430 | ≤0.12 | ≤0.75 | ≤1.00 | ≤0.040 | ≤0.03 | 16.00~18.00 | - | ||||

| 2205 | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.030 | ≤0.015 | 22.00~23.00 | 4.5~6.5 | 2.5~3.5 | |||

| 2507 | ≤0.03 | ≤0.08 | ≤1.20 | ≤0.035 | ≤0.015 | 24.00~26.00 | 6.00~8.00 | 3.0~5.0 | |||

| 904L | ≤0.02 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 19.00~23.00 | 23.00~28.00 | 4.0~5.0 | 1.0~2.0 | ||

INCONEL 028 | ≤0.03 | ≤1.00 | ≤2.50 | ≤0.030 | ≤0.030 | ≤28.0 | ≤34.0 | ≤4.0 | ≤1.4 | ||

MONEL 400 | ≤0.30 | ≤0.5 | ≤2.00 | - | ≤0.024 | - | ≥63.0 | - | ≤34.0 | ||

INCONEL 800 | ≤0.10 | ≤1.00 | ≤1.50 | - | ≤0.015 | ≤23.0 | ≤35 | 4.0~5.0 | - | ≤0.75 | Ti≤0.6 Al≤0.6 |

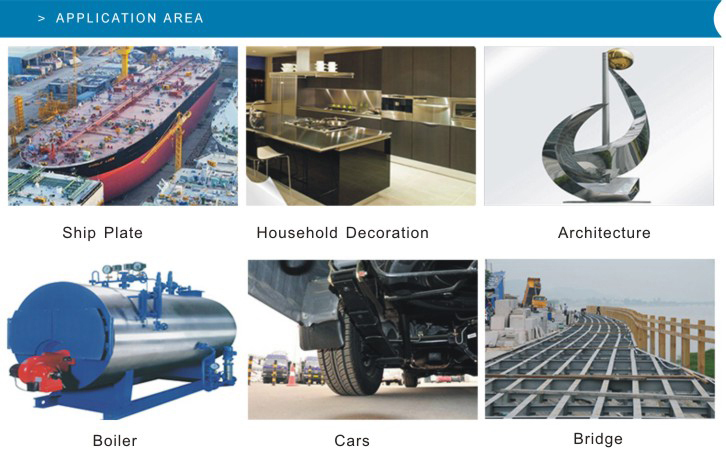

Architectural/Civil Engineering: Cladding, handrails, door and window fittings, street furniture, structural sections, enforcement bar, lighting columns, lintels, masonry supports.

Transport: Exhaust systems, car trim/grilles, road tankers, ship containers, ships chemical tankers, refuse vehicles.

Chemical/Pharmaceutical: Pressure vessels, process piping.

Oil and gas: Platform accommodation, cable trays, sub-sea pipelines.

Medical: Surgical instruments, surgical implants, food processing.

Food and Drink: Catering equipment, brewing, distilling, food processing.

Water: Water and sewage treatment, water tubing, hot water tanks.

General: Springs, fasteners(bolts, nuts and washers) wire.

Click here to get more information

![]()

1. HS CODE: 7219339000,7219320000,7219220000,7219110000

2. Trade term: FOB,CNF,CIF

3. Payment term: 30% by T/T as down payment balance against B/L copy or 100% LC at sight.

4. Delivery time: Within 3-15 working days after received deposit or LC draft.

5. A copy of mill test certificate will be provided with shipment.

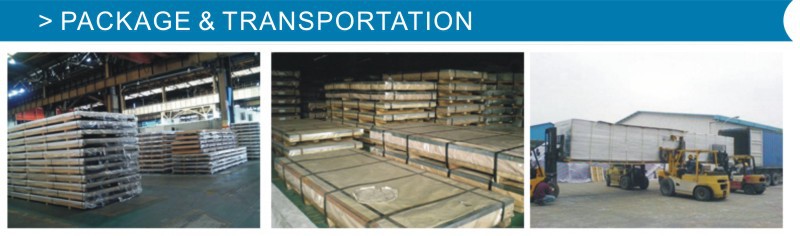

Packaging & Shipping

Standard export package: In wooden cases,in wooden pallets or as customer’s request.

The inner size of container:

20ft container: 5.8m(Length)*2.13m(Width)*2.18m(High) 23-26CBM

40ft container: 11.8m(Length)*2.13m(Width)*2.72m(High) 68CBM

We will make the products with good surface protected,our packages are totally according to international exporting standard.

- Q: What is the corrosion resistance of stainless steel sheets in saltwater?

- Stainless steel sheets have excellent corrosion resistance in saltwater environments. The high levels of chromium present in stainless steel enable the formation of a passive oxide layer on the surface, which acts as a protective barrier against corrosion. This oxide layer is highly resistant to saltwater, preventing the metal from being directly exposed to the corrosive effects of the saltwater. Additionally, stainless steel alloys such as 316 and 316L contain molybdenum, which further enhances their resistance to pitting and crevice corrosion in saltwater. Overall, stainless steel sheets are a preferred choice for applications in saltwater environments due to their exceptional corrosion resistance properties.

- Q: Can stainless steel sheets be used for decorative wall panels?

- Yes, stainless steel sheets can be used for decorative wall panels. Their sleek and modern appearance, durability, and resistance to corrosion make them a popular choice for adding a decorative touch to walls in various settings such as homes, offices, restaurants, or commercial spaces.

- Q: Can stainless steel sheets be used for water treatment equipment?

- Yes, stainless steel sheets can be used for water treatment equipment. Stainless steel is highly resistant to corrosion, making it suitable for applications involving water treatment, where exposure to moisture and chemicals is common. It is also easy to clean and maintain, making it an ideal choice for water treatment equipment that requires frequent sanitization.

- Q: Can stainless steel sheets be used for wastewater treatment?

- Certainly, wastewater treatment can employ stainless steel sheets. Stainless steel boasts remarkable corrosion resistance and can endure harsh chemicals and environments, rendering it an optimal substance for wastewater treatment purposes. Its utility extends to the construction of tanks, pipes, and other equipment employed in the treatment procedure. Moreover, stainless steel sheets are effortlessly cleaned and maintained, diminishing the chances of contamination. Furthermore, stainless steel qualifies as a sustainable material since it can be recycled, thereby presenting an environmentally conscious option for wastewater treatment facilities.

- Q: What are the standard sizes and thicknesses of stainless steel sheets?

- Stainless steel sheets are utilized in numerous industries and applications due to their wide range of standard sizes and thicknesses. Typically, the standard sizes vary from 4 feet by 8 feet to 5 feet by 10 feet, but customized sizes can also be obtained based on specific needs. In terms of thickness, stainless steel sheets are offered in various standard options. These include 20 gauge (0.036 inches), 18 gauge (0.048 inches), 16 gauge (0.060 inches), 14 gauge (0.075 inches), 12 gauge (0.105 inches), and 10 gauge (0.135 inches). It is important to note that these thicknesses indicate the nominal thickness, and the actual thickness may have slight variations. Additionally, it is worth noting that stainless steel sheets are also available in metric sizes. Common thicknesses in metric sizes range from 0.5 mm to 3 mm. This provides flexibility and compatibility with international standards and specifications. In summary, the standard sizes and thicknesses of stainless steel sheets are determined by industry standards and customer requirements. This ensures their widespread availability and versatility for various applications such as construction, automotive, aerospace, and kitchen equipment manufacturing, among others.

- Q: How do I bend or form stainless steel sheets?

- To bend or form stainless steel sheets, you can follow these steps: 1. Choose the appropriate stainless steel grade: Stainless steel comes in various grades, each with specific properties. Select the grade that best suits your project's requirements, considering factors like corrosion resistance, strength, and formability. 2. Use the right tools: To bend stainless steel sheets, you will need specific tools such as a hydraulic press brake or a metal bending machine. These tools apply force evenly to achieve precise and consistent bends. Make sure to use tools that are designed for stainless steel to avoid damaging the material. 3. Prepare the stainless steel sheet: Before bending, ensure that the stainless steel sheet is clean and free from any dirt or debris. Additionally, mark the desired bending lines on the sheet using a pencil or tape to guide you during the process. 4. Determine the bending angle and radius: Determine the angle and radius of the bend you want to achieve. This will depend on the specific requirements of your project. Use a protractor or a template to measure and mark the desired angles accurately. 5. Secure the stainless steel sheet: To prevent movement or slipping during the bending process, securely clamp the stainless steel sheet to the bending tool or machine. This will ensure stability and accuracy during the bending process. 6. Apply pressure gradually: Start the bending process slowly and gradually increase the pressure. This prevents the stainless steel sheet from cracking or warping. Monitor the bending carefully to ensure that the desired shape is achieved without any defects or deformation. 7. Repeat if necessary: If you need to create multiple bends or complex shapes, repeat the process as required. Ensure that each bend is carefully measured and aligned with the previous bends to achieve a consistent and accurate result. 8. Finishing touches: After bending the stainless steel sheet, remove any residual marks or burrs using a file or sandpaper. This will give your finished product a smooth and polished appearance. Remember, bending stainless steel sheets can be challenging, especially for thicker gauges or harder grades. It is advisable to practice on scrap pieces or seek professional assistance if you are unsure or lack experience in working with stainless steel.

- Q: What are the different types of stainless steel sheet surface textures available?

- There are several different types of stainless steel sheet surface textures available, each with its own unique aesthetic appeal and functional properties. Some of the most common surface textures include: 1. No.1 Finish: This is the most common and widely used surface finish for stainless steel sheets. It has a smooth, reflective surface that is achieved by hot rolling the steel and then annealing it. 2. No.2B Finish: This finish has a slightly rougher texture compared to No.1 finish. It is achieved by cold rolling the steel and then annealing it, resulting in a dull, matte appearance. 3. No.4 Finish: Also known as satin or brushed finish, this surface texture has a fine grain appearance with short, parallel lines. It is achieved by polishing the surface with abrasive belts or brushes. 4. Hairline Finish: This surface texture is similar to No.4 finish but has a finer grain appearance. It is achieved by polishing the surface with abrasive belts or brushes in a unidirectional pattern. 5. No.8 Mirror Finish: This is the most reflective surface texture available for stainless steel sheets. It has a highly polished and mirror-like appearance, achieved by further polishing the surface after No.4 finish. 6. Bead Blasted Finish: This surface texture is achieved by blasting the stainless steel sheet with fine glass beads or ceramic particles. It results in a textured, non-reflective surface with a uniform matte appearance. 7. Embossed Finish: This surface texture involves imprinting a pattern or design onto the stainless steel sheet. It can be achieved through mechanical embossing or by using a special roller during the manufacturing process. 8. Colored Finishes: Stainless steel sheets can also be coated with various colors to enhance their visual appeal. These colored finishes are achieved through processes like PVD (Physical Vapor Deposition) or powder coating, resulting in a durable and vibrant surface. These are just some of the many surface textures available for stainless steel sheets, each offering its own distinct look and feel. The choice of the surface texture depends on the desired aesthetic, functional requirements, and the specific application of the stainless steel sheet.

- Q: Can stainless steel sheets be used for electrical or electronic applications?

- Indeed, stainless steel sheets are applicable for both electrical and electronic purposes. Due to its remarkable electrical conductivity and resistance to corrosion, stainless steel proves to be an optimal material for a diverse range of electrical components. Electrical enclosures, switchgear, control panels, and various other electrical equipment commonly incorporate stainless steel. Moreover, its versatility allows stainless steel sheets to be fabricated into different forms and dimensions, rendering them suitable for a variety of electronic applications like printed circuit boards (PCBs), connectors, and terminals. Furthermore, the durability and ability to withstand high temperatures make stainless steel the preferred choice for electrical and electronic purposes in harsh environments.

- Q: Are stainless steel sheets good for heat exchanger tubes?

- Stainless steel sheets are widely employed as heat exchanger tubes owing to their remarkable heat transfer capabilities and resistance to corrosion. The thermal conductivity of stainless steel is notably high, enabling efficient heat transfer between fluids. Moreover, its exceptional resistance to corrosion is vital for heat exchangers that frequently encounter corrosive liquids or gases. The longevity and reliability of stainless steel sheets guarantee the durability of heat exchanger tubes, making them a favored option in diverse industries like chemical processing, power generation, and HVAC systems.

- Q: What is the maximum thickness available for stainless steel sheets?

- The maximum thickness available for stainless steel sheets can vary depending on the specific grade of stainless steel and the manufacturing capabilities of the supplier. However, in general, stainless steel sheets can be found in thicknesses ranging from 0.5mm to 80mm. It is important to note that thicker sheets are typically used for specialized applications that require increased strength and durability, such as construction projects or heavy machinery. When selecting stainless steel sheets, it is crucial to consider the intended use and consult with a reputable supplier to ensure that the desired thickness is available.

Send your message to us

ASTM A480 Jis Sus 409 Stainless Steel Plate Pheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords