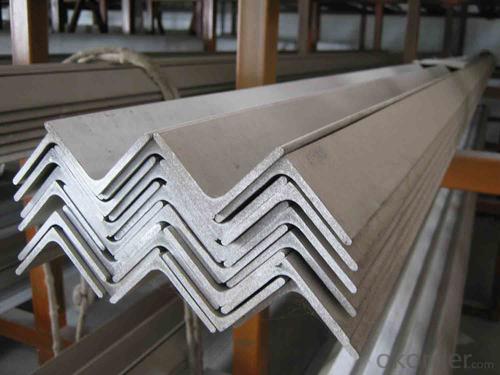

Angle Steel High Quality Hot Rolled GB Q235 Q345B ALL SIZES

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Hot Rolled Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Sizes: 25mm-250mm | ||||||||||||

a*t | ||||||||||||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 | ||||||||||

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 | ||||||||||

36*3.0-5.0 | 80*5.0-10 | 150*10-20 | ||||||||||

38*2.3-6.0 | 90*7.0-10 | 160*10-16 | ||||||||||

40*3.0-5.0 | 100*6.0-12 | 175*12-15 | ||||||||||

45*4.0-6.0 | 110*8.0-10 | 180*12-18 | ||||||||||

50*4.0-6.0 | 120*6.0-15 | 200*14-25 | ||||||||||

60*4.0-8.0 | 125*8.0-14 | 250*25 | ||||||||||

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What makes stainless steel stainless?

A3: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: How do steel angles contribute to the overall torsional stiffness of a structure?

- Steel angles can contribute to the overall torsional stiffness of a structure in several ways. Firstly, steel angles have a high moment of inertia, which means they are resistant to bending. This resistance to bending helps to distribute and resist the torsional forces acting on the structure, reducing any twisting or warping that may occur. Secondly, steel angles can be strategically placed and connected in a structure to form bracing or reinforcement systems. These systems help to transfer and distribute torsional forces throughout the structure, preventing localized areas from experiencing excessive twisting or distortion. Furthermore, steel angles can be used to create rigid connections between different structural members, such as beams or columns. These connections enhance the overall stiffness of the structure by effectively transmitting torsional forces between the connected members, minimizing any relative movement or deformation. Moreover, steel angles can also be utilized as diagonal members in truss structures or frames. By introducing diagonals, the angles help to resist and distribute torsional forces, maintaining the overall stability and rigidity of the structure. Overall, steel angles play a crucial role in enhancing the torsional stiffness of a structure by providing resistance to bending, forming bracing or reinforcement systems, creating rigid connections, and acting as diagonal members. By effectively managing and distributing torsional forces, steel angles contribute to the overall stability, durability, and performance of the structure.

- Q: Are steel angles suitable for balcony railings?

- Yes, steel angles are suitable for balcony railings. Steel angles are strong, durable, and can withstand the elements, making them a reliable choice for balcony railings. They provide stability and support to ensure the safety of individuals using the balcony. Additionally, steel angles can be customized and designed in various styles, making them aesthetically pleasing for balcony railings.

- Q: Can steel angles be used for handrail supports?

- Yes, steel angles can be used for handrail supports. Steel angles are commonly used as a structural element in construction and can provide sufficient strength and stability to support handrails.

- Q: What are the common sizes of steel angles?

- The sizes of steel angles can differ based on the industry and specific project requirements. However, there are several standard sizes that are commonly utilized. In the United States, the most readily accessible steel angles are available in widths of 1/2 inch, 1 inch, 1-1/2 inches, and 2 inches. Typically, these angles have thicknesses ranging from 1/8 inch to 1/4 inch. Furthermore, larger and smaller angles can also be found for specialized applications. These specialized angles may include wider angles measuring up to 8 inches or more, or thinner angles with thicknesses as low as 1/16 inch. It is important to acknowledge that these sizes might vary in different countries or regions, and suppliers may have their own specific range of sizes. Thus, it is advisable to consult with local suppliers or manufacturers to determine the most prevalent sizes of steel angles in a particular area.

- Q: Are steel angles resistant to wind loads?

- Yes, steel angles are generally resistant to wind loads due to their high strength and structural integrity.

- Q: Are there any limitations on the angle of inclination for steel angles?

- Yes, there are limitations on the angle of inclination for steel angles. The angle of inclination refers to the angle at which the steel angle is installed or positioned in a structure. The limitations on this angle depend on various factors, including the type and thickness of the steel angle, the load it is expected to bear, and the specific design and engineering requirements of the structure. In general, steel angles can be installed at various angles of inclination, ranging from vertical (90 degrees) to horizontal (0 degrees). However, there are practical limitations that need to be considered. Steel angles are typically designed to bear loads in a specific direction, and deviating too far from the intended angle of inclination can impact their structural integrity and load-bearing capacity. Furthermore, the installation angle of steel angles may be limited by the connection methods used. Welding, bolting, or other fastening techniques may have specific requirements for the angle of inclination to ensure proper connection strength and stability. It is important to consult the relevant building codes, standards, and engineering guidelines to determine the specific limitations on the angle of inclination for steel angles in a particular application. Professional structural engineers can provide the necessary expertise and guidance to ensure that the steel angles are installed within safe and appropriate limits.

- Q: What are the common methods of surface preparation for steel angles?

- The common methods of surface preparation for steel angles include grinding, sandblasting, and chemical cleaning. Grinding is a mechanical method where the surface of the steel angle is smoothed and leveled using an abrasive wheel or disc. This method is effective in removing rust, scale, and other surface imperfections. It is commonly used for small-scale projects or when a smooth surface finish is not critical. Sandblasting, also known as abrasive blasting, involves propelling small particles at high speeds onto the surface of the steel angle. This method is highly effective in removing mill scale, rust, paint, and other contaminants. Sandblasting provides a roughened surface that promotes better adhesion of coatings or paints. It is commonly used in large-scale industrial projects where a high-quality surface finish is required. Chemical cleaning involves using chemical solutions to remove contaminants from the surface of the steel angle. This method is effective in removing rust, oil, grease, and other organic materials. Chemical cleaning can be done through various techniques such as immersion or brush application. It is commonly used when sandblasting or grinding may not be feasible or practical. In addition to these methods, other surface preparation techniques may include power tool cleaning, flame cleaning, or a combination of methods depending on the specific requirements of the project. It is important to choose the appropriate method based on the condition of the steel angle, the desired surface finish, and the intended application of the steel angle.

- Q: How do you transport and ship steel angles?

- To ensure the safe and efficient delivery of steel angles, careful planning and proper handling are required. The following are important steps to consider in the transportation and shipping process: 1. Proper packaging is essential to prevent damage during transit. Steel angles can be bundled together with steel bands or placed on pallets to ensure their security and stability. 2. Consider the size and weight of the steel angles before shipping. This information is crucial for determining the appropriate transportation mode and selecting the right shipping containers or vehicles. 3. Various transportation modes can be used for steel angles, such as trucks, trains, ships, or planes. The choice depends on factors like distance, urgency, and cost. Trucks or trains are commonly used for domestic shipments, while ships or planes are preferred for international shipments. 4. Loading and securing the steel angles correctly is necessary to prevent any movement or damage during transit. Proper lifting equipment should be used to evenly distribute and secure the angles to prevent shifting or falling. 5. It is advisable to obtain insurance coverage for the steel angles during transportation to protect against unforeseen circumstances. Additionally, proper documentation, including bills of lading, shipping labels, and customs paperwork, should be prepared and attached to the shipment to facilitate smooth transit and customs clearance. 6. Compliance with regulations is important when shipping steel angles. This includes adhering to weight restrictions, obtaining necessary permits or licenses, and following any special handling or safety guidelines. 7. Effective tracking and monitoring systems should be in place throughout the transportation and shipping process. This provides real-time visibility of the shipment's location, ensuring timely delivery and allowing for prompt intervention in case of any issues or delays. By following these steps and collaborating with experienced logistics partners, you can transport and ship steel angles safely and efficiently, minimizing the risk of damage or delays.

- Q: Are steel angles suitable for high-temperature applications?

- Yes, steel angles are suitable for high-temperature applications. Steel is known for its high strength and durability, and it retains its structural integrity even at elevated temperatures. Additionally, steel angles can withstand thermal expansion and contraction without deformation or failure, making them a reliable choice for high-temperature environments.

- Q: Can steel angles be used for pipe supports?

- Yes, steel angles can be used for pipe supports. Steel angles provide a strong and durable option for supporting pipes due to their structural integrity and load-bearing capabilities. The L-shaped design of steel angles offers excellent stability and can be easily mounted to walls, ceilings, or other structural elements. Additionally, steel angles can be welded or bolted together to create custom configurations that suit specific pipe support requirements. Their versatility, strength, and ease of installation make steel angles a popular choice for pipe support applications in various industries such as construction, plumbing, and manufacturing.

Send your message to us

Angle Steel High Quality Hot Rolled GB Q235 Q345B ALL SIZES

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords