Aluzinc coated galvanized steel sheet AFP SGCL

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 14567 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Galvalume should not be used on, in, or around concrete or mortar. Concrete and mortar are highly

alkaline environments. Bare Galvalume and painted Galvalume sheets suffer rapid corrosion when

in contact with mortar and concrete. Bare Galvanized and painted Galvanized perform better in this

type of environment.

Standard and Grade :

Hot-dip Aluzinc steel coils | ||||

ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 | AS- 1397-2001 | |

Commercial quality | CS | DX51D+AZ | SGLCC | G1+AZ |

Structure steel | SS GRADE 230 | S220GD+AZ | SGLC400 | G250+AZ |

SS GRADE 255 | S250GD+AZ | SGLC440 | G300+AZ | |

SS GRADE 275 | S280GD+AZ | SGLC490 | G450+AZ | |

SS GRADE 340 | S320GD+AZ | SGLC570 | G450+AZ | |

SS GRADE 550 | S350GD+AZ | G500+AZ | ||

S550GD+AZ | G550+AZ | |||

Application :

Production of cold formed corrugated sheet and profiles for roofing, cladding, decking, tiles, sandwich

walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

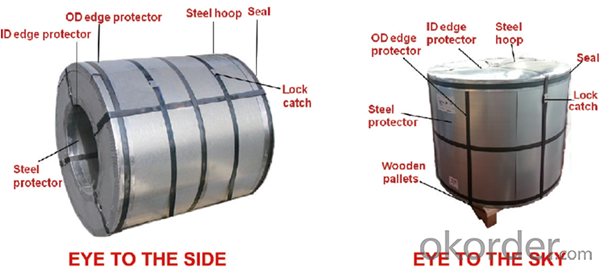

Packaging & Shipping

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the

specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers.

For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for

Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q: How do you cut a steel sheet?

- To cut a steel sheet, you will need to use the appropriate tools and techniques. Here are a few common methods: 1. Power tools: The most common power tool used for cutting steel sheets is an angle grinder equipped with a cutting disc. Make sure to wear safety goggles and gloves while operating the grinder. Mark the cutting line on the sheet using a marker or chalk, then slowly and steadily guide the grinder along the marked line to cut through the steel. 2. Shears: If you are cutting a thin steel sheet, you can use manual or electric shears. These tools have a scissor-like cutting mechanism specifically designed for cutting metal. Place the steel sheet between the blades of the shears, aligning the cutting line with the blades, and apply steady pressure to cut through the sheet. 3. Plasma cutting: This method is best suited for thicker steel sheets. Plasma cutting involves using a high-velocity jet of ionized gas (plasma) to melt and sever the metal. It requires specialized equipment, such as a plasma cutter, which uses an electric arc to create the plasma jet. 4. Waterjet cutting: Another effective method for cutting steel sheets is waterjet cutting. It uses a high-pressure jet of water mixed with an abrasive substance (such as garnet) to cut through the metal. This technique is ideal for complex shapes and precise cuts, but it requires specialized machinery. Before attempting to cut a steel sheet, always prioritize safety. Wear appropriate protective gear, such as safety glasses, gloves, and a face shield if necessary. Additionally, ensure that you are working in a well-ventilated area to avoid inhaling any fumes or particles generated during the cutting process.

- Q: Are steel sheets available in different patterns or textures?

- Yes, steel sheets are available in different patterns and textures.

- Q: How do steel sheets perform in terms of weather resistance?

- Steel sheets are known for their exceptional weather resistance properties. Due to their composition and protective coatings, steel sheets are highly resistant to various weather conditions such as rain, snow, and wind. They have the ability to withstand extreme temperatures, both hot and cold, without any significant deterioration or damage. Additionally, steel sheets are also highly resistant to corrosion, making them an ideal choice for outdoor applications and areas with high humidity or saltwater exposure. The weather resistance of steel sheets helps to ensure their longevity and durability, making them a reliable option for various construction and industrial purposes.

- Q: Can steel sheets be used for insulation cladding?

- No, steel sheets are not typically used for insulation cladding. Insulation cladding is usually made of materials with thermal insulation properties such as foam boards, mineral wool, or fiberglass. These materials are chosen for their ability to reduce heat transfer and improve energy efficiency. Steel sheets, on the other hand, are commonly used for structural purposes or as a protective layer due to their strength and durability. While steel sheets can provide some level of protection, they do not possess the necessary insulation properties to effectively prevent heat or cold transfer. Therefore, it is recommended to use appropriate insulation materials specifically designed for cladding purposes.

- Q: How do steel sheets handle bending or flexing?

- Steel sheets are known for their excellent strength and rigidity, making them highly resistant to bending or flexing. The inherent properties of steel, such as its high tensile strength and stiffness, allow it to withstand substantial external forces without deforming. Steel sheets can handle bending or flexing to a certain extent without compromising their structural integrity, making them suitable for a wide range of applications. When steel sheets are subjected to bending or flexing forces, they undergo a process known as elastic deformation. This means that the steel will temporarily change shape under the applied load, but it will return to its original form once the load is removed. This elasticity is due to the crystalline structure of steel, which allows it to absorb and distribute the stress evenly throughout its structure. However, it is important to note that steel sheets do have a limit to their bending or flexing capabilities. Beyond a certain point, the applied load can cause the steel to undergo plastic deformation, which results in permanent changes to its shape. This can lead to the formation of cracks or fractures in the material. The maximum amount of bending or flexing that steel sheets can tolerate before experiencing plastic deformation is determined by factors such as the thickness of the sheet, the grade and type of steel used, and the specific application requirements. To enhance the flexibility of steel sheets, certain processes such as cold rolling or annealing can be employed. Cold rolling involves passing the steel sheet through rollers at ambient temperature, which not only increases its strength but also improves its ability to withstand bending or flexing forces. Annealing, on the other hand, involves heating the steel to a specific temperature and then cooling it slowly to relieve internal stresses, making it more ductile and less prone to cracking. In conclusion, steel sheets are highly capable of handling bending or flexing due to their inherent strength, rigidity, and elasticity. However, it is essential to consider the specific application requirements and the limitations of the steel sheet to ensure its performance and longevity.

- Q: Why should the back of the steel sheet pile cofferdam be pumped after the construction of the pile cap?

- The appearance of surface defects of steel sheet pile, length, width, thickness, end rectangle ratio, flatness and lock shape content of inspection, do not meet the requirements of steel sheet pile is corrected, in order to reduce the difficulties in piling process.

- Q: What is the thickness range of steel sheets?

- The thickness range of steel sheets can vary depending on the specific type and application, but it typically ranges from 0.4 millimeters to 6 millimeters.

- Q: How do steel sheets compare to plastic sheets?

- Steel sheets are generally stronger, more durable, and have a higher heat resistance compared to plastic sheets. They are better suited for heavy-duty applications, such as construction and industrial uses, where strength and durability are crucial. Plastic sheets, on the other hand, are lightweight, flexible, and cost-effective. They are commonly used for applications where weight and cost are important factors, such as packaging, signage, and some consumer goods. Ultimately, the choice between steel and plastic sheets depends on the specific requirements and intended use of the sheets.

- Q: What is the yield strength of steel sheets?

- The yield strength of steel sheets can vary depending on the type and grade of steel being used. However, typically, common carbon steel sheets have a yield strength ranging from 250 MPa to 400 MPa.

- Q: Can steel sheets be used for electrical motors?

- Yes, steel sheets can be used for electrical motors. Steel is commonly used in the construction of motor cores as it provides high magnetic permeability, low hysteresis, and low eddy current losses, which are essential for efficient operation of electrical motors.

Send your message to us

Aluzinc coated galvanized steel sheet AFP SGCL

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 14567 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords