Aluzinc Steel Sheet in Coil with Prime Quality and Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluzinc Steel Coil Description:

Hot-dip aluzinc steel sheet is substrated on cold rolled steel(CRC) in various strength and specification. Coating composition is 55% aluminium in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent corrosion and heat resistance performance. It is especially useful for countless outdoor and industrial applications.

2.Main Features of the Galvanized Steel Coil:

• Base material for countless outdoor and industrial applications

• Excellent corrosion resistance

• Excellent heat resistance performance

• High strength

• Good formability

• Rust- proof ability

• Good visual effect

3. Aluzinc Steel Coil Images

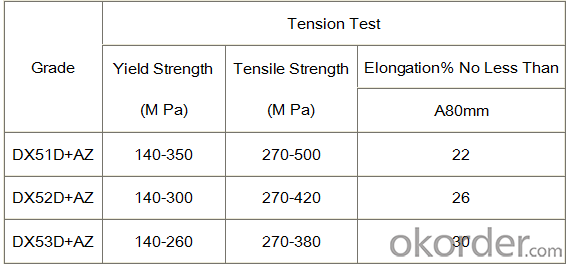

4.Aluzinc Steel Coil Specification

Thickness: 0.3-0.7mm

Width: 914-1250mm

Inner Diameter: 508-610mm

Weight of Steel Coil: 3-15MT

Coating Type: Al-Zn Alloy

Available Dipped Layer: 50-150g/m2

Surface Finish Structure: Normal Spangle & Small Spangle & Zero Spangle

Available Surface Treatment: Passivating & Oiling & AFP & Filming

5.FAQ of Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the typical lead times for ordering steel coils?

- The typical lead times for ordering steel coils can vary depending on several factors, including the supplier, the quantity and specifications of the coils, as well as the current market conditions. However, on average, lead times can range from a few weeks to a couple of months. It is always recommended to contact the specific supplier for more accurate information regarding lead times.

- Q: How are steel coils stored?

- Steel coils are typically stored in warehouses or outdoor storage yards. They are usually stacked on top of each other in a crisscross pattern to maximize space utilization and prevent them from rolling. Additionally, steel coils may be secured with steel banding or placed on pallets to ensure stability during storage and transportation.

- Q: What is the size range of steel coils?

- The size of steel coils can vary depending on the specific application and industry, offering a wide range of options. Steel coils are available in various sizes to meet different needs. The width of steel coils can range from a few inches to several feet, accommodating different requirements. Similarly, the thickness of steel coils can vary from very thin gauges, like 0.005 inches, to thicker gauges that exceed 0.5 inches. The length of steel coils is typically determined by the manufacturing process, but it can be customized to meet specific demands. In general, the size range of steel coils is extensive, providing flexibility and adaptability in industries like automotive, construction, and manufacturing.

- Q: What are the common standards and specifications for steel coils?

- The common standards and specifications for steel coils include ASTM A36/A36M, ASTM A572/A572M, ASTM A1011/A1011M, and ASTM A653/A653M. These standards outline the requirements for the chemical composition, mechanical properties, dimensions, and other characteristics of steel coils used in various industries, such as construction, automotive, and manufacturing. Additionally, international standards like EN 10025 and JIS G3101 are also commonly followed in different regions.

- Q: What are the different types of steel coil edge condition options?

- There are several different types of steel coil edge condition options available, each with its own unique characteristics and advantages. Some of the most common types include: 1. Mill Edge: This is the most basic and common type of steel coil edge condition. It is produced during the hot rolling process and is characterized by a naturally rough and uneven edge. Mill edge coils are typically used for applications where the edge quality is not critical, such as in general fabrication. 2. Slit Edge: Slit edge coils are created by cutting the edges of the steel coil using a slitting machine. This process produces a smoother and more uniform edge compared to mill edge coils. Slit edge coils are often preferred for applications that require a higher level of precision, such as in automotive or electrical industries. 3. Trim Edge: Trim edge coils are similar to slit edge coils but with an additional trimming process to remove any defects or imperfections from the edges. This results in an even smoother and cleaner edge, making trim edge coils ideal for applications where appearance and aesthetic quality are important, such as in architectural or decorative purposes. 4. Deburred Edge: Deburred edge coils undergo a deburring process to remove any sharp or burr-like edges. This is done to ensure safety and prevent injury during handling or processing of the coils. Deburred edge coils are commonly used in industries where worker safety is a priority, such as in construction or manufacturing. 5. Rounded Edge: Rounded edge coils have their edges rounded off to eliminate any sharp corners or edges. This type of edge condition is often used in applications where the coils will come into contact with delicate materials or surfaces, as it helps to prevent scratching or damage. It is important to note that the choice of steel coil edge condition will depend on the specific requirements of the application and the desired outcome. Each type of edge condition offers its own unique benefits, and it is crucial to consider factors such as precision, appearance, safety, and functionality when selecting the appropriate option.

- Q: Does anyone know if there is any info on Steel Manufacturing techniques, utilyzing electro/mechanical methods in order to create carbon nanotubes from the %C already inherant in the steel. In other words just modifying the Geometry of the Carbon the already makes up some of the steel.

- I don't think that would work. First off, there's not enough carbon in steel - even very high carbon steels are only about 2% carbon. Second, the iron atoms in steel form a crystal lattice, in the shape of a cube, with another iron atom in the middle of the cube. Each cube is about 0.3 nm per side. Carbon atoms work their way into the crystals and displace the iron atoms. But a carbon nanotube is around 1 nanometer in diameter - that's 3 times as big as the iron lattice! So a nanotube wouldn't fit. One thing you might do, however, is make a composite - mix the materials together on a scale a little bigger than the atomic scale that the iron and carbon mix to make steel. Just like a carbon fiber bicycle frame or ski pole is strands of carbon (much bigger and not as strong as nanotubes) held together with epoxy, you could hold nanotube strands together with metal. Not sure it would be good for armor, but if you can figure out a way to do it, I'm sure someone will come up with a use for it!

- Q: What are the common uses of coated steel coils?

- Coated steel coils are commonly used in various industries for applications such as automotive manufacturing, construction, and appliance production. These coils are utilized in the production of metal roofs, siding, garage doors, HVAC systems, and electrical appliances. The coating on the steel provides protection against corrosion, enhances durability, and improves aesthetics, making it an ideal choice for these applications.

- Q: What are the dimensions of steel coils used in the oil and gas industry?

- The dimensions of steel coils used in the oil and gas industry vary depending on the specific application and requirements. However, common dimensions for steel coils in this industry typically range from 0.5mm to 3mm in thickness and 600mm to 2000mm in width. The length of the coils can vary, but they are often around 2000mm to 6000mm.

- Q: I know that carbon steels and alloy steels are different but are carbon steels still alloys?Thanks!

- Carbon steel, or plain-carbon steel, is a metal alloy. It is a combination of two elements, iron and carbon. Depending upon the amount of presence of carbon in the alloy, Carbon steel can be classified into 4 different categories- Low Carbon Steel Medium Carbon Steel High Carbon Steel Very High Carbon Steel

- Q: Are steel coils used in agricultural equipment manufacturing?

- Yes, steel coils are commonly used in agricultural equipment manufacturing. Steel coils are used to create various components such as frames, brackets, and supports, which are essential for the construction and durability of agricultural equipment. The strength and versatility of steel make it a preferred material choice for manufacturing agricultural machinery.

Send your message to us

Aluzinc Steel Sheet in Coil with Prime Quality and Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords