Aluminum Window Screen Sheets 18 X 6 - Aluminium Plate/Aluminum Sheet/Aluminium Chequer Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium plate/aluminium sheet

1. | Item | Aluminum plate/ Aluminum sheet,aluminium plate price, aluminium chequer plate,aluminium sheet,aluminium sheet price | |

2. | Standard | ATSTM,AISI,JIS,EN,GB | |

3. | Material | 1060,1200,1100,a1100P,3003,3004,5052,5652,5154,5254,5454,5083, 5086,5056,5456,2A21,2024,2014,6061,6063,7072,7075,etc. | |

4. | Specifications | Thickness | 0.5mm~200mm |

Width | 100mm~3000mm | ||

Length | 2m,3m,5.8m,6m,or as required | ||

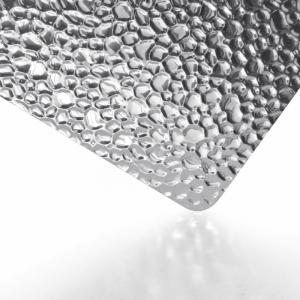

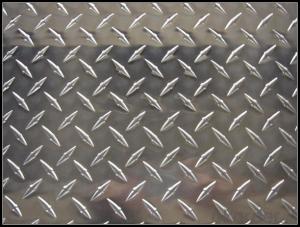

6. | Surface | Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc.

| |

7. | Price Term | Ex-work, FOB, CIF , CFR, etc. | |

8. | Payment Term | T/T, L/C, Western Union, etc. | |

9. | Delivery Time | According to order’s quantity. | |

10. | Package | Export standard package: bundled wooden box, suit for all kinds of transport, or be required. | |

11. | MOQ | 500kg | |

12. | Export to | Singapore,Indonesia,Ukraine,Korea,Thailand, Viet Nam, Saudi Arabia, Brazil, Spain, Canada, USA, Egypt, Iran, India, Kuwait, Dubai, Oman, Kuwait, Peru, Mexico, Iraq,Russia,Malaysia, etc. | |

13. | Application | 1) Kitchenware, food and chemical products processing and storage devices; 2) Aircraft fuel tanks, oil pipe, rivets, wire; 3) Cans cover, car body panels, steering plates, stiffeners, brackets and other components; 4) Manufacturing trucks, tower building, ship, train, furniture, machinery parts, precision machining with the tubes, rods, shaped, sheet metal. | |

14. | Contact | If you have any question, please feel free contact me . | |

Container Loading Capacity | |||||

Type | Length | Width | Height | Volume | Max Weight |

20FT GP | 5.8m | 2.13m | 2.18m | 24-26 CBM | 25 MT |

40FT GP | 11.8m | 2.13m | 2.18m | 54 CBM | 25 MT |

40FT HP | 11.8m | 2.13m | 2.72m | 68 CBM | 26 MT |

According to the quantity or volume,you can choose! | |||||

FCL(full container load); LCL(less than container load); or Bulk-cargo. | |||||

Packaging & Delivery

| Packaging Details: | Export standard package, suit for all kinds of transport, or as required. |

| Delivery Detail: | Prompt delivery,or as order's quantity. |

- Q: What is made when Aluminium and Hydrochloric Acid reacts? It makes a dense white smoke with a metallic odour in the gas. Could it be dissolved amounts of Aluminium Chloride or small amounts of unreacted Aluminium in the gas? Or could be that the Chlorine (in equilibrium with HCl and HClO) made chlorates and perchlorates of aluminium that give off odours?Don't tell me the gas isn't supposed to have an odour. I know what diatomic Hydrogen smells like. Nothing. That's the way it should be. But unfortunately, that's not the way it is.

- i might call the plumber immediately. curiously there's a hollow interior the piping someplace, and the sulfuric acid would desire to have eaten by in spite of advance into clogging that hollow. I doubt that it will supply up leaking via itself, to no longer point out that acid is in all risk leaking into your kitchen in the present day.

- Q: Can aluminum sheets be used for cookware?

- Cookware can indeed utilize aluminum sheets. Due to its exceptional heat conductivity and lightweight nature, aluminum remains a favored material for cookware. In the construction of cooking utensils like pots, pans, and baking sheets, aluminum sheets frequently serve as the base or core material. To enhance durability and user-friendliness, these sheets are often coated with a nonstick or ceramic layer. Nonetheless, it is crucial to recognize that pure aluminum can react with certain acidic or alkaline foods, resulting in a metallic taste or discoloration. To prevent such occurrences, most aluminum cookware is anodized or coated, establishing a barrier between the food and the aluminum surface. All in all, aluminum sheets prove to be an adaptable and widely employed option for cookware in both professional and domestic kitchens.

- Q: Are aluminum sheets prone to warping?

- Yes, aluminum sheets can be prone to warping under certain conditions. Aluminum is a relatively soft metal, meaning it is more susceptible to bending or distorting compared to other metals like steel. However, the extent to which aluminum sheets warp depends on various factors such as the thickness of the sheet, the specific alloy used, the temperature it is exposed to, and the level of stress applied to it. Thinner aluminum sheets are generally more prone to warping as they have less structural integrity. Thicker sheets, on the other hand, are more resistant to warping due to their increased rigidity. Additionally, the specific alloy composition of the aluminum sheet can influence its susceptibility to warping. Temperature fluctuations can also cause aluminum sheets to warp. When exposed to high temperatures, aluminum expands, and if not properly supported or restrained, it may bend or warp. Similarly, rapid cooling can cause contraction, resulting in warping. Lastly, the level of stress applied to aluminum sheets can contribute to warping. Excessive bending, pressure, or unevenly distributed loads can cause the sheet to deform. To minimize warping, it is important to handle aluminum sheets with care, support them adequately during temperature changes, and avoid applying excessive stress. Additionally, using thicker aluminum sheets or choosing certain alloys with higher tensile strength can help mitigate the risk of warping.

- Q: ive been working with parts for a robot without gloves and ive manged to 3 cuts in my fingers, also my hands get covered with powdered aluminum from sanding the peices, can this be dangerous to my health?

- When working with aluminum, wear leather gloves to protect your hands, goggles to protect your eye and a dust mask to protect your lungs. Aluminum has been linked to Alzheimer's and other neurological conditions.

- Q: Can aluminum sheets be plasma cut?

- Yes, aluminum sheets can be plasma cut. Plasma cutting is an effective method for cutting aluminum sheets as it utilizes a high-temperature plasma arc to melt and remove the metal, resulting in clean and precise cuts.

- Q: just bought a hobart handler 140 (already love it), and was just wondering on what gas to use for aluminum. my welder will be set up for mild steel (75% argon 25% CO2). it would be nice to be able to use this mix with aluminum as well, as it would be easy to just switch spools of wire, but the manual says to use a 100% argon mix when welding with aluminum. will the 25% CO2 make a difference welding aluminum?

- I can't find a reference, but I think aluminum may react with CO2. Aluminum is produced by reacting aluminum oxide with carbon when electrical energy is injected, so I guess that the reaction may go backwards and produce energy

- Q: What are the different methods of surface cleaning for aluminum sheets?

- There are several methods of surface cleaning for aluminum sheets, including mechanical cleaning such as sanding or grinding, chemical cleaning using solvents or acidic solutions, and electrolytic cleaning which involves using an electric current to remove contaminants. Additionally, ultrasonic cleaning and steam cleaning are also commonly used methods to clean aluminum surfaces.

- Q: Can aluminum sheets be an alternative to glass in certain applications?

- Yes, aluminum sheets can be an alternative to glass in certain applications. Aluminum sheets offer several advantages over glass, making them a suitable choice in specific scenarios. Firstly, aluminum sheets are lightweight and durable, making them ideal for applications where weight is a concern, such as in aerospace or automotive industries. Glass, on the other hand, is relatively heavy and brittle, which can limit its use in certain environments. Additionally, aluminum sheets have excellent corrosion resistance, making them suitable for applications in marine or coastal environments where glass may deteriorate over time due to exposure to saltwater. Aluminum sheets also have a high strength-to-weight ratio, allowing for greater design flexibility and structural integrity compared to glass. Moreover, aluminum sheets can provide better thermal insulation properties compared to glass. They offer improved heat transfer resistance, which can be advantageous in applications where temperature control is crucial, such as in the construction industry. Furthermore, aluminum sheets can be more cost-effective than glass in certain applications. The production and installation costs of aluminum sheets are often lower compared to glass, making them a more economical choice for large-scale projects. However, it is important to note that glass still has its own unique properties and advantages that make it the preferred choice in many applications, such as its transparency and optical clarity. Glass also offers better resistance to scratches and chemical corrosion compared to aluminum sheets. In conclusion, while aluminum sheets can be a viable alternative to glass in certain applications due to their lightweight, durability, corrosion resistance, thermal insulation properties, and cost-effectiveness, the choice between the two materials ultimately depends on the specific requirements and constraints of the application in question.

- Q: Okay guys i need to rapir a crack on an aluminum pipe , would durafix do the job ?? If so where can i get this durafix ? at my local home depot ?

- I've only found these type products online or at flea markets. It works quite well after a little practice.

- Q: There are about 200 holes on the aluminum plate to be machined. There are 100 M12 thread holes, and the rest are 15MM through holes. The tolerance is +0.02. Seeking detailed processing technology, is the first hole or first processing plane, how to control the amount of deformation of the plate, if the milling process can not guarantee flatness, on the grinder, then the 2 surfaces to stay 2MM margin? Are there any 15MM through holes that can be used to maintain tolerances, or do they need to be boring?. Great God advice, the best detail. Aluminum so much done before, no experience, if it does it scrapped.

- Such a large plate flatness 0.1 you don't need it, basically do not, we used 1000*700 processing board, directly buy imported aluminum plate, ensure the factory within 0.05, leveling back after processing to find professional leveling company OK, I was also called grinding waste, the deformation of grinding plate will be great, so there is no need to consider

Send your message to us

Aluminum Window Screen Sheets 18 X 6 - Aluminium Plate/Aluminum Sheet/Aluminium Chequer Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords