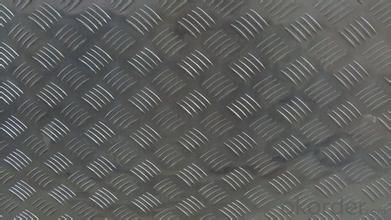

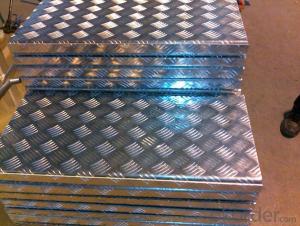

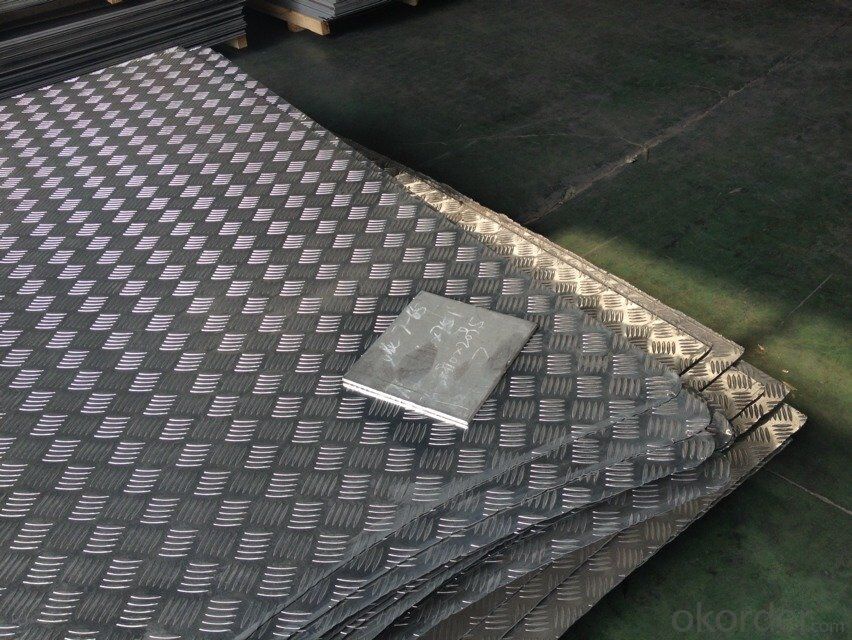

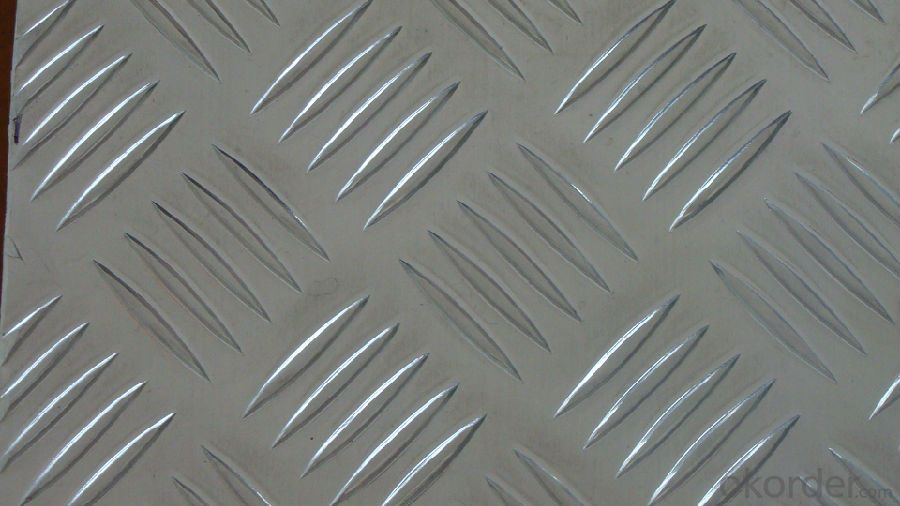

Aluminum Foil Sheets 5 X 5 - Aluminium Tread / Chequer Plate 5 Bar 1.5mm, 2mm, 3mm, 4.5mm, 6mm Various Sizes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

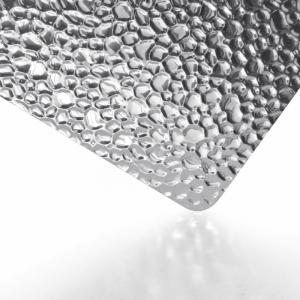

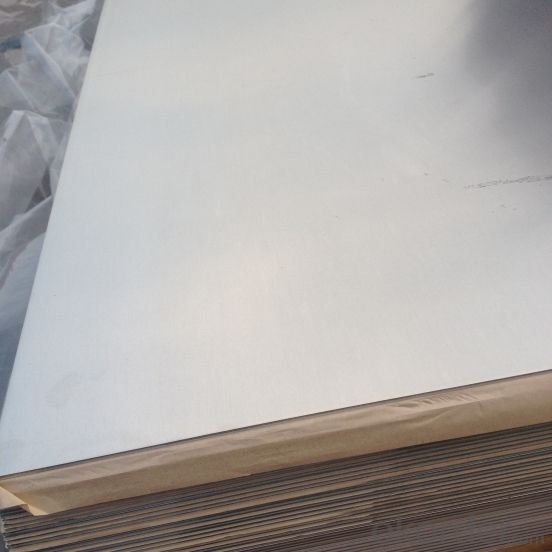

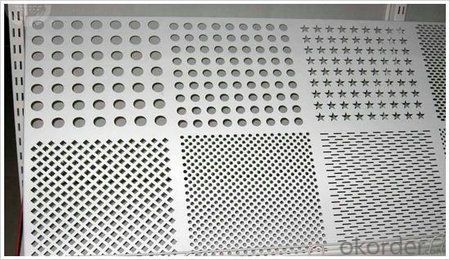

aluminum chequered plate are widely usd for bus, cars and shipping vessel as the floor....

Aluminum tread plate is also called anti-slide aluminum sheet which is widely used in manufacturing vehicles, ships, washing machines, refrigerator shell, etc.

Specification:

Alloy: 1050, 1060, 1100, 3003, 3105, 5052

Temper: O, H12, H14, H16, H18, H22, H24, H26, H32

Thickness: 1.0~10mm

Width: 1000~1600mm

Length: 1000~6000mm

Packing:

One roll in an individual box or printed PP bag

Certain quantities in a standard carton

Depends on customer’s request

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q: Are the aluminum sheets suitable for manufacturing food processing equipment?

- Yes, aluminum sheets are suitable for manufacturing food processing equipment. Aluminum is a highly versatile and durable material that is known for its corrosion resistance, lightweight nature, and ability to withstand high temperatures. These qualities make it ideal for use in the food processing industry, as it ensures the equipment is hygienic, easy to clean, and can withstand the demanding conditions of food production.

- Q: Are there any health risks associated with using aluminum sheets?

- Yes, there are potential health risks associated with using aluminum sheets. Aluminum is a neurotoxic metal that can accumulate in the body over time. Prolonged exposure to high levels of aluminum has been linked to several health issues, including respiratory problems, bone disorders, and neurodegenerative diseases such as Alzheimer's. Additionally, certain studies suggest a possible link between aluminum exposure and an increased risk of developing breast cancer. It is important to take precautions when working with aluminum sheets and minimize exposure to the metal.

- Q: as for heating coil and aluminum sheet, which one is better for heating?

- Both of them have advantage. It depends on the new product type it’s applied. Heating coil: it’s applied in some products with high temperature and large heat release, such as oven and other types.

- Q: Are aluminum sheets suitable for outdoor applications?

- Yes, aluminum sheets are suitable for outdoor applications. Aluminum is a highly durable and corrosion-resistant material, making it ideal for use in outdoor environments. It can withstand exposure to various weather conditions, including rain, snow, and sunlight, without deteriorating or losing its structural integrity. Additionally, aluminum sheets can be coated or painted to enhance their resistance to fading, scratching, and other forms of wear and tear. This makes them perfect for outdoor applications such as roofing, siding, signage, and decorative elements. Moreover, aluminum is lightweight and easily malleable, allowing for easy installation and customization. Overall, aluminum sheets are a reliable and long-lasting choice for outdoor projects.

- Q: What are the primary components that make up aluminum sheets?

- <p>Aluminum sheets are primarily composed of aluminum, which is a lightweight and malleable metal. They are made from pure aluminum or aluminum alloys, which may include small percentages of other elements to enhance specific properties such as strength, corrosion resistance, or workability. Common alloying elements include copper, magnesium, manganese, silicon, and zinc. The exact composition varies depending on the specific grade of aluminum and its intended use. Pure aluminum is soft and not commonly used for sheets; instead, alloys are preferred for their improved strength and durability.</p>

- Q: the coil is wrapped around the aluminium pipe will it effect the efficiency of the coil gun ?

- Yes, it absorbs most magnetic force generate by coil and turns it into useless current .

- Q: Can aluminum sheets be used for storage tanks?

- Indeed, storage tanks can make use of aluminum sheets. Due to its lightweight nature and resistance to corrosion, aluminum proves to be a fitting option for the containment of diverse substances, including water, chemicals, and fuel. Its remarkable durability allows it to endure even the harshest environmental conditions. Moreover, constructing and maintaining aluminum tanks is comparatively straightforward. Nonetheless, it is crucial to take into account the specific necessities of the substance being stored and seek guidance from professionals or engineers to ascertain that aluminum sheets are the suitable selection for the given storage tank.

- Q: Are aluminum sheets suitable for use as materials for windows and doors?

- <p>Yes, aluminum sheets can be used for windows and doors. They are known for their durability, low maintenance, and resistance to corrosion and weathering. Aluminum windows and doors are energy-efficient, lightweight, and offer excellent security. They can also be easily customized in terms of size and design, and are often used in modern architecture for both residential and commercial buildings.</p>

- Q: Does exposure to ultraviolet (UV) rays impact the properties or longevity of aluminum sheets?

- <p>Aluminum sheets are generally resistant to UV rays, which means they do not degrade or corrode due to exposure to sunlight or UV radiation. Aluminum has a high reflectivity and can reflect most of the UV rays, minimizing the impact on its surface. However, prolonged exposure can cause a slight change in color, known as patina, which is a natural oxidation process and does not compromise the integrity or strength of the material. Overall, aluminum maintains its properties well under UV exposure, making it a suitable material for outdoor applications.</p>

- Q: Are aluminum sheets suitable for packaging applications?

- Aluminum sheets are well-suited for packaging applications, as they have excellent barrier properties, durability, and a lightweight nature. The packaging industry widely utilizes aluminum due to its impermeability to gases, water vapor, light, and microorganisms. This makes it an ideal material for preserving the freshness and quality of products like food, beverages, pharmaceuticals, and cosmetics. Moreover, aluminum sheets offer exceptional protection against external factors that can potentially compromise the integrity of packaged goods. Moisture, oxygen, and UV radiation are effectively blocked, which helps extend shelf life and maintain product quality. Additionally, aluminum is non-toxic, odorless, and tasteless, ensuring that there is no interaction between the packaging material and the contents. In terms of versatility, aluminum can be used in various packaging formats such as cans, trays, foils, and laminates. Its malleability allows for the production of complex shapes and designs, providing convenience and branding opportunities for manufacturers. Furthermore, aluminum is highly recyclable, making it a sustainable choice for packaging applications. The recycling process requires significantly less energy compared to primary production, and aluminum can be recycled repeatedly without losing its properties. This helps reduce the environmental impact of packaging waste and supports the concept of a circular economy. In conclusion, aluminum sheets possess numerous advantages that make them highly suitable for packaging applications. Their effective protection, versatility, and sustainability make them an excellent choice for industries in need of reliable and high-quality packaging solutions.

Send your message to us

Aluminum Foil Sheets 5 X 5 - Aluminium Tread / Chequer Plate 5 Bar 1.5mm, 2mm, 3mm, 4.5mm, 6mm Various Sizes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords