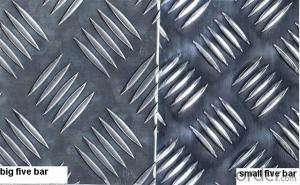

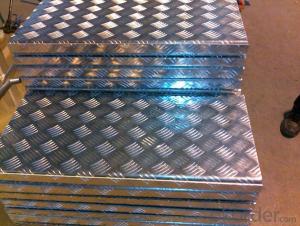

Aluminum Trailer Skin Sheets - Big/Small Five Bar Treadplate Series 1/3/5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specifications of Big Five Bar Treadplate

Original Price | USD1930 |

Current Price | USD1850 |

Alloy | AA1100 CC |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 1.5mm- 1.0mm |

Width: | 1000mm-1300mm |

Standard: | GB/T17748-1999, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

2. Usage/Application of Big Five Bar Treadplate

The embossed aluminum coil/sheet are widely used for decorative purpose in construction, packing and appliance. It is also very commonly used for anti-splippery purposes in vehicles and public places.

3. Packaging & Deliveryof Big Five Bar Treadplate

Seaworthy package, plastic bag covered inside, carton wrapped outside, paper core, on the wooden pallet. Pallet weight: 2000-25000KG.

Shipment: The goods will be delivered in not more than 40 days after getting the buyer's prepayment.

4. Production Flow of Big Five Bar Treadplate

Melting-Rolling- Cutting- Annealing--Packing

- Q: Explain the distinctions between aluminum sheets and aluminum foil in terms of thickness, uses, and properties.

- <p>Aluminum sheets and aluminum foil are both made from aluminum but differ in thickness and applications. Aluminum sheets are thicker and more rigid, typically used for construction, manufacturing, and as a packaging material. They offer better strength and durability. Aluminum foil, on the other hand, is very thin and flexible, commonly used for food packaging, cooking, and insulation. It's lightweight and has excellent heat and light reflection properties. Aluminum sheets are often anodized or coated for additional properties, while foil is valued for its purity and malleability.</p>

- Q: are there any carbonated mineral water that are produced in aluminium cans.

- Aluminium cans have an oxide covering on them so the reaction between them and the carbonated water is so little if any that it can't be noticed. Aluminium is also not so high on the reactivity series

- Q: What is the bending radius for aluminum sheets?

- The bending radius of aluminum sheets may vary depending on the sheet's thickness and alloy. In general, thinner sheets (around 1-3 mm) should have a bending radius of approximately 1.5 times their thickness. On the other hand, thicker sheets (over 3 mm) can increase the bending radius to around 2.5 times their thickness. Nevertheless, it's important to bear in mind that these are general guidelines and the bending radius may need to be adjusted according to the specific application and desired outcome. To obtain accurate bending radius information, it is always recommended to seek advice from a professional or consult the manufacturer's technical data sheets.

- Q: What are the safety considerations when handling and working with aluminum sheets?

- When handling and working with aluminum sheets, there are several safety considerations that should be taken into account. Firstly, it is important to wear appropriate personal protective equipment (PPE). This includes safety glasses or goggles to protect the eyes from any potential flying debris or metal shards. Additionally, gloves should be worn to protect the hands from sharp edges or cuts. Secondly, it is crucial to handle aluminum sheets with care, as they can be quite sharp. When lifting or moving the sheets, it is recommended to use gloves and other tools to minimize the risk of injury. Additionally, it is important to be mindful of the weight of the sheets to avoid strains or back injuries. Another safety consideration is the potential for fire hazards. Aluminum is a highly flammable material, especially in the form of fine dust or shavings. Therefore, it is important to keep the work area clean and free from any loose aluminum debris. It is also advisable to have appropriate fire extinguishing equipment nearby and to be aware of the location of emergency exits. Furthermore, when cutting or shaping aluminum sheets, it is important to use proper techniques and tools. Using the appropriate saws or shears can help minimize the risk of injury. It is also important to secure the sheets properly to prevent them from moving or falling during the cutting process. Lastly, it is important to be aware of any potential health hazards associated with aluminum. Aluminum dust or fumes can be harmful if inhaled, so it is important to work in a well-ventilated area or use respiratory protection if necessary. In summary, the safety considerations when handling and working with aluminum sheets include wearing appropriate PPE, handling the sheets with care, minimizing fire hazards, using proper cutting techniques and tools, and being aware of potential health hazards. By following these precautions, the risks associated with working with aluminum sheets can be minimized, ensuring a safe working environment.

- Q: Our production needs a large number of plating aluminum plate, consult domestic and imported aluminum plate difference?

- Guangdong Huayuan prosperous is the largest aluminum plate supplier 021-56808701, in Shanghai / Tianjin / Chongqing have logistics and storage, domestic aluminum plating surface coating treatment is less than imports, stamping coating is easy to fall,

- Q: Aluminum alloy cable tray is made of a series of aluminum sheets, a series of pure aluminum aluminum plate can do?

- 6 Department of the bar, pure aluminum is too soft, in fact, the price of 6 series with pure aluminum prices on the strength of almost guaranteed.

- Q: What is the maximum width available for aluminum sheets?

- The maximum width of aluminum sheets can differ depending on the manufacturer and specific specifications. Typically, aluminum sheets can be found in widths up to 72 inches or 1.83 meters. It should be emphasized that certain manufacturers may provide wider choices for specialized purposes. Furthermore, personalized dimensions can be acquired by placing specific orders, providing more freedom in selecting the desired width.

- Q: Some say you should use the 'dull' side of aluminum foil when cooking etc. There's something potentially bad about the shiny side.True or not?

- Straight from Reynolds: Which side of Reynolds Wrap? Aluminum Foil should I use, the shiny or the dull side? Actually, it makes no difference which side of the aluminum foil you use—both sides do the same fine job of cooking, freezing and storing food. The difference in appearance between dull and shiny is due to the foil manufacturing process. In the final rolling step, two layers of foil are passed through the rolling mill at the same time. The side coming in contact with the mill's highly polished steel rollers becomes shiny. The other side, not coming in contact with the heavy rollers, comes out with a dull or matte finish. The exception is when using Reynolds Wrap? Release? Non-Stick Aluminum Foil. The non-stick coating is applied during manufacturing to the dull side of the foil. Always place the non-stick (dull) side toward the food.

- Q: Can aluminum sheet be used for aerospace applications?

- Yes, aluminum sheet can be used for aerospace applications. Aluminum is a widely used material in the aerospace industry due to its desirable properties such as lightweight, high strength, and corrosion resistance. It is commonly used in the construction of aircraft fuselages, wings, and structural components. Aluminum sheets are often used in the fabrication of aircraft panels, where their high strength-to-weight ratio allows for improved fuel efficiency and increased payload capacity. Additionally, aluminum sheets can be easily formed, machined, and welded, making them versatile and suitable for various aerospace applications.

- Q: This question asks for a method to measure the thickness of an aluminum sheet.

- <p>To determine the thickness of an aluminum sheet, you can use a micrometer or a caliper, which are precise measuring tools. Place the sheet on a flat surface and measure from one side to the other at multiple points to account for any inconsistencies. Alternatively, you can use an ultrasonic thickness gauge, which is especially useful for non-contact measurements. For a quick estimate, a simple ruler can give you a rough idea, but for high precision, specialized tools are necessary. Always ensure the measuring device is calibrated and used correctly to get accurate results.</p>

Send your message to us

Aluminum Trailer Skin Sheets - Big/Small Five Bar Treadplate Series 1/3/5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords