Aluminum Trailer Siding Sheets Oregon - Embossed & Coated Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

We are able to supply 1,2,3,5,6,8 series alloy coil, foil and sheets, including 1***, 3***, 3104, 5052, 5182, 5754, 5083,5086,8011,8079

Our products include:

1). Mill-finished aluminum coil:

Alloy: AA1050, 1060, 1100, AA3003, 3005, 3015, 5052, 5754, 5083,8011 ,8079etc.

Temper: H14/16/18/22/24/32, HO etc.

Thickness: 0.08mm—100mm

Width: 100mm—2200mm (Can be slitted)

Notice: Embossment can be done if required.

2). Color-Coated Aluminum Coil:

Alloy : AA1050/1100/3003/3005/3105/5005/5052/8079 etc.

Thickness: 0.03mm—1.50mm

Width: 10mm—1600mm (Can be slitted)

Coating : PVDF, PE

Coating thickness: Usually 16-25 micron, could be33-40 micron

Color : According to customers’ requirements

Notice : Embossment can be done if required

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

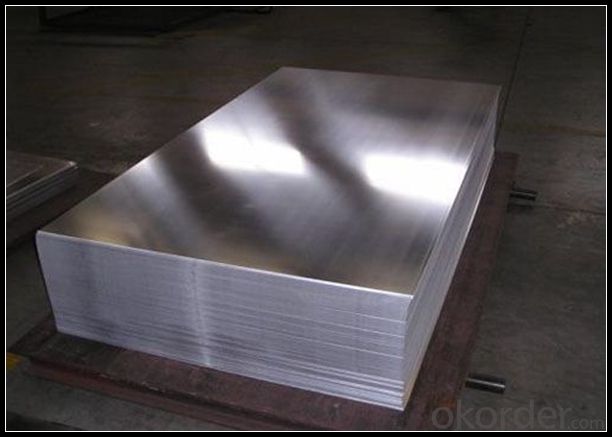

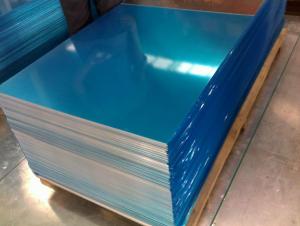

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? |

A: Normally it would be 40days after received your deposit. |

Q: Can you provide free samples? |

A: Yes, free samples will be sent to you on freight at destination. |

Q: Can I get your latest catalogue? |

A: Yes, it will be sent to you in no time. |

Q: What is the MOQ? |

A: 3 tons |

Q: What are your payment terms? |

A: We accept L/C, D/A, D/P, T/T, West Union,etc |

- Q: This question seeks to understand the specific characteristics of aluminum sheets that make them suitable for various applications.

- <p>Aluminum sheets possess several properties that make them versatile for different applications: 1. Corrosion resistance: Aluminum forms a protective oxide layer, which makes it resistant to corrosion. 2. Lightweight: Aluminum is lighter than many other metals, which is beneficial for applications where weight is a concern. 3. High strength-to-weight ratio: Despite being lightweight, aluminum is strong and durable. 4. Good thermal and electrical conductivity: Aluminum conducts heat and electricity well, making it ideal for heat sinks and electrical components. 5. Formability: Aluminum can be easily shaped and bent, which is useful in construction and manufacturing. 6. Recyclability: Aluminum is highly recyclable, reducing waste and environmental impact. 7. Reflectivity: Aluminum reflects light and heat, which is useful in applications like solar reflectors and insulation. These properties vary in importance depending on the specific application, such as construction, automotive, aerospace, or consumer goods.</p>

- Q: What are the common uses of aluminum sheets?

- Aluminum sheets have a wide range of common uses across various industries. They are often used in construction for roofing, siding, and structural components due to their lightweight and durable nature. In the transportation sector, aluminum sheets are utilized in the manufacturing of vehicles, including cars, airplanes, and boats, to reduce weight and improve fuel efficiency. Additionally, aluminum sheets are commonly used in packaging, electrical appliances, and signage due to their corrosion resistance and ability to be easily formed into different shapes.

- Q: Can aluminum sheet be used for architectural applications?

- Aluminum sheet is indeed suitable for architectural purposes, thanks to its impressive strength, durability, and resistance to corrosion. It is widely utilized in the construction field for various architectural applications such as cladding, roofing, and facades. Architects and designers can select aluminum sheets in different thicknesses to meet their specific aesthetic and functional requirements. These sheets can be easily shaped, bent, and formed to create distinctive architectural elements like panels, screens, louvers, and decorative features. Moreover, aluminum sheets can be coated or finished to enhance their appearance and protect them from environmental factors. Techniques such as anodizing, powder coating, or painting can be employed to improve the material's resilience against weathering, UV radiation, and pollution. Due to its lightweight nature, aluminum is favored for architectural applications as it reduces the overall weight of the structure and facilitates convenient installation. Additionally, aluminum is an environmentally friendly option for architectural projects as it can be recycled infinitely, thus promoting sustainability. To summarize, aluminum sheets are a highly viable and popular choice for architectural purposes because of their strength, versatility, durability, and aesthetic appeal.

- Q: What types of aluminum sheets are recommended for outdoor use due to their properties?

- <p>Yes, there are specific types of aluminum sheets designed for exterior applications. These include aluminum sheets with protective coatings such as anodized aluminum, which offers enhanced resistance to corrosion and weathering. Additionally, aluminum sheets with a PVDF (Polyvinylidene Fluoride) coating, such as Kynar 500, are highly suitable for exterior use due to their excellent durability and resistance to UV rays, chemicals, and scratches. These coatings help maintain the aluminum's appearance and integrity over time, making them ideal for outdoor applications where exposure to the elements is a concern.</p>

- Q: Can aluminum sheets be used for heat sinks in LED lighting?

- Indeed, heat sinks in LED lighting can utilize aluminum sheets. Aluminum possesses remarkable heat conductivity, which renders it a perfect substance for dispersing the heat emitted by LED lights. By employing aluminum sheets as heat sinks, the heat generated by the LED chips is effectively transferred away, thereby averting overheating and extending the lifespan of the LED lighting system. Furthermore, aluminum's lightweight nature, resistance to corrosion, and affordability further contribute to its widespread adoption as a heat sink material in LED lighting.

- Q: How do aluminum sheets perform in terms of impact resistance?

- Aluminum sheets are known for their exceptional impact resistance capabilities. Due to their high strength-to-weight ratio, aluminum sheets can withstand significant forces without deforming or breaking. This makes them an ideal choice for applications that require protection against impact, such as in the construction, automotive, and aerospace industries. One of the key reasons behind aluminum's impressive impact resistance is its inherent toughness. It can absorb and distribute energy from an impact, enabling it to withstand sudden forces and shocks. Additionally, aluminum's ability to deform elastically allows it to absorb energy by bending and flexing, thus minimizing the impact's effect on the material. Furthermore, aluminum sheets can be further enhanced in terms of impact resistance through various techniques, such as alloying and heat treatment. Alloying aluminum with other elements like copper, manganese, or magnesium can improve its strength and impact resistance by creating a more robust alloy. Heat treatment processes like tempering or annealing can also refine the microstructure of aluminum, enhancing its mechanical properties and impact resistance. In summary, aluminum sheets exhibit excellent impact resistance due to their high strength-to-weight ratio, inherent toughness, and ability to deform elastically. With advancements in alloying and heat treatment techniques, the impact resistance of aluminum sheets can be further improved to meet the specific requirements of various industries.

- Q: What is the reflectivity of aluminum sheets?

- The reflectivity of aluminum sheets is quite high, typically ranging from 80% to 95%, which makes them excellent for various applications that require high levels of reflection, such as mirrors, solar panels, and decorative surfaces.

- Q: what were the cinergy field (riverfront stadium, cincinnati, oh) seats made of? were they metal or aluminum? i know they were silver under the red paint...

- If Cinergy isn't the concentration of the drawing, it particularly is probable in simple terms th at they have not as much as date the drawing of the skyline. If there's an indicator on the packaging layout, then removing the stadium might require them to resubmit the trademark utility, and that they probable do no longer evaluate it relatively easily worth the difficulty.

- Q: What's the difference between 6061 aluminum plate, 7075 aluminium plate and 6063 aluminum plate?

- Simply put, 6061 and 6063 belong to the 6 series, 6061 hardness in 90HB 6063 in 80HB, suitable for brazing, surface oxidation treatment is better,

- Q: Can aluminum sheets be used for elevator interiors?

- Indeed, elevator interiors can certainly be constructed using aluminum sheets. Aluminum has gained significant popularity as a material of choice for elevator interiors due to its multitude of advantageous qualities. Its lightweight nature, durability, and resistance to corrosion render it highly suitable for long-term utilization in elevator applications. With ease, aluminum sheets can be skillfully fabricated and shaped to perfectly fit the dimensions and design specifications of elevator interiors. Furthermore, aluminum can be enhanced with various types of coatings or finishes, such as anodizing or powder coating, to not only augment its aesthetic appeal but also provide additional protection. Overall, aluminum sheets represent a practical and widely utilized option for elevator interiors within the industry.

Send your message to us

Aluminum Trailer Siding Sheets Oregon - Embossed & Coated Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords