Aluminum Trailer Siding Sheets - Coated Metal Aluminum Alloy Sheet from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We can offer various kinds of coated aluminum sheets:

- Standard Alloy: 1100, 1050. And 3003, 3005, 3105 and etc. could be accepted too.

- Standard width: 1240mm, 1270mm. And it is accepted from 120mm to 1590mm

- Thickness: 0.10mm to 0.60mm

- Coating thickness: polyester coating>= 17 micron. pvdf coating >= 25 mircon.

- Hardness (pencil hardness) more than 2H

- Adhesion: 5B (EN ISO-2409: 1994)

- Impact resistance :No cracking and peeling(A.S.T.M D2794-1993)

- MEK resistance more than 100

- Color : there are 30 stardard colors according to our color chart. And you color is accepted if you could post us a sample.

- Shippment: 15 days for standard width & standard alloy. If specials, delivery time need to be confirmed order by order.

Applications:

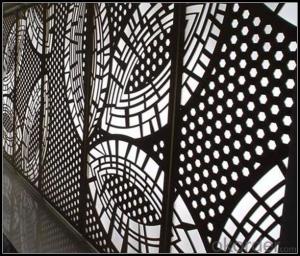

Used to manufacture decorative material, such as aluminium composite panel, brushed panel, lampshade, and other composite panels.

1) Exterior applications such as: wall cladding, facades, roofs and canopies, tunnels, column covers or renovations

2) Interior applications such as: wall cladding, ceilings, bathrooms, kitchens and balconies

3) Advertisement and market applications such as: display platforms, signboards, fascias and shop fronts

4) Transport and industry applications

FAQ

Price term: Ex-Work,FOB,CNF,CFR,DDP,DDU,or as required

Payment term:TT,L/C,Western Union,by cash,or as required

Delivery Time: Prompt delivery,or based on the quantity of order.

- Q: 6061 what is the density of the aluminum plate?

- 6061 aluminum plate density:6061 aluminum plate is aluminum alloy, the density is calculated according to 2.9g/cm3.Calculation method:Aluminium plate weight (kg) =0.0000029 * * * * width * lengthAluminium tube weight (kg) =0.0000029 * wall thickness * (outside diameter wall thickness) * lengthFormula for weight calculation of aluminium bars (kg) =0.0000029 * radius * radius * length

- Q: How do you prevent oxidation of exposed edges of aluminum sheets?

- To prevent oxidation of exposed edges of aluminum sheets, there are a few effective methods that can be employed: 1. Apply a protective coating: One of the most common ways to prevent oxidation is by applying a protective coating on the exposed edges of aluminum sheets. This can be done using various types of coatings, such as paint, lacquer, or a specialized protective coating designed specifically for aluminum. These coatings act as a barrier, preventing the aluminum from coming into contact with oxygen and moisture, which are the primary causes of oxidation. 2. Use anodizing: Anodizing is a process in which a protective oxide layer is created on the surface of aluminum. By subjecting the aluminum sheets to an electrolytic process, a controlled and thick layer of oxide is formed, which acts as a barrier against oxidation. Anodizing also provides additional benefits such as improved corrosion resistance and enhanced aesthetics. 3. Implement proper storage and handling: Proper storage and handling practices can also help prevent oxidation of exposed edges. Aluminum sheets should be stored in a dry and well-ventilated area, away from moisture and humidity. It is important to avoid storing aluminum sheets directly on the ground or other surfaces that may cause them to come into contact with moisture. Additionally, gloves should be worn during handling to minimize the transfer of oils from the skin, which can accelerate oxidation. 4. Regular cleaning and maintenance: Regular cleaning and maintenance of aluminum sheets can help prevent oxidation. This involves removing any dirt, grime, or other contaminants that may accumulate on the surface, as they can contribute to the oxidation process. Cleaning can be done using mild soaps or detergents, and a soft cloth or sponge. After cleaning, it is important to thoroughly dry the aluminum sheets to remove any remaining moisture. By implementing these preventive measures, the oxidation of exposed edges of aluminum sheets can be effectively minimized, ensuring their longevity and maintaining their aesthetic appeal.

- Q: Is it possible to construct furniture using aluminum sheets?

- <p>Yes, you can use aluminum sheets to make furniture. Aluminum is a lightweight, durable, and corrosion-resistant material that is often used in modern furniture design. It can be easily shaped and welded, making it suitable for a variety of furniture pieces such as tables, chairs, and shelving. However, it's important to consider the design and structural integrity, as well as the finish and comfort, when creating furniture with aluminum. It's also advisable to use appropriate tools and techniques to ensure safety and quality in the construction process.</p>

- Q: Can aluminum sheets be polished?

- Yes, aluminum sheets can be polished. Aluminum is a relatively soft metal, which makes it easier to polish compared to harder metals like stainless steel. Polishing aluminum sheets involves using abrasive materials such as sandpaper or polishing compounds to remove any imperfections, scratches, or oxidation on the surface. The process typically involves several stages of polishing with different grits of sandpaper or polishing compounds, gradually achieving a smoother and more reflective surface. Polished aluminum sheets are commonly used in various applications, including automotive parts, architectural elements, and decorative items, as the polishing process enhances the metal's appearance and provides a lustrous and reflective finish.

- Q: What are the different surface finishes available for aluminum sheets?

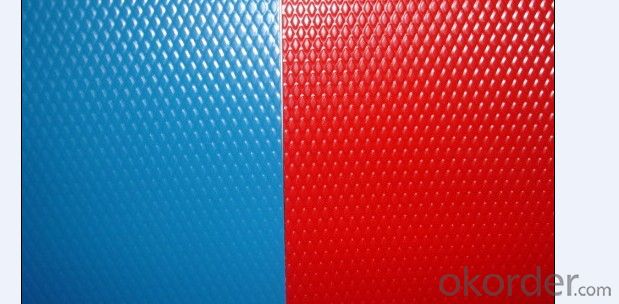

- There are several different surface finishes available for aluminum sheets, each offering distinct characteristics and aesthetic appeal. Some of the commonly used surface finishes for aluminum sheets include: 1. Mill Finish: This is the most basic surface finish and is achieved by leaving the aluminum in its as-rolled condition, without any additional treatment. It has a smooth and shiny appearance, but may have minor imperfections and is not as durable as other finishes. 2. Anodized Finish: Anodizing is an electrochemical process that creates a protective layer on the surface of the aluminum sheet. This finish enhances corrosion resistance, improves durability, and provides a wide range of color options. Anodized finishes can have a matte or glossy appearance. 3. Brushed Finish: This finish is achieved by brushing the aluminum sheet with a fine abrasive material, creating a textured pattern. This finish is commonly used for decorative purposes and provides a unique and attractive appearance. 4. Polished Finish: Polishing the aluminum sheet using abrasive materials creates a smooth and reflective surface. This finish is often used for decorative purposes and gives a high-end, mirror-like appearance to the aluminum. 5. Embossed Finish: Embossing is a process that creates raised or recessed patterns on the surface of the aluminum sheet. This finish is commonly used for decorative purposes, as it adds texture and visual interest to the material. 6. Powder Coated Finish: Powder coating involves applying a dry powder to the aluminum sheet and then curing it under heat. This finish provides a durable and weather-resistant coating, and is available in a wide range of colors and textures. 7. Patterned Finish: Patterned finishes are achieved by imprinting different patterns or designs on the surface of the aluminum sheet. This finish is often used for architectural applications and adds visual interest to the material. These are just a few examples of the different surface finishes available for aluminum sheets. The choice of finish depends on the desired appearance, functionality, and application requirements.

- Q: is there aluminum oxide on the surface of aluminum sheet after being polished by abrasive paper?

- aluminum will be oxided as aluminum oxide once being exposed in air.

- Q: What is the maximum temperature resistance of aluminum sheets?

- Aluminum sheets can generally withstand temperatures up to approximately 600 degrees Fahrenheit (315 degrees Celsius), but this may differ due to factors like alloy composition, thickness, and treatment. When contemplating the use of aluminum sheets for high-temperature purposes, it is crucial to refer to the manufacturer's specifications or seek professional guidance.

- Q: I need help with this question for a report i'm doing, it's about recycling aluminium, please could you give me some reasons why to recycle aluminium and eg.saves energy, and how it does eg. saves energy by...Thanks a lot this will help me loads.P.S this is just a report for my science project.

- Aluminum has to be extracted from the earth which is costly and takes a lot of energy. Then the aluminum needs to be smelted out of the rock that it is in, again this takes a lot of energy and creates toxins. Aluminum like all metals are finite, we conserve resources and the land where they will need to be extracted by recycling it.

- Q: This question asks for a comparison of the benefits and drawbacks of using aluminum sheets as a roofing material.

- <p>Aluminum sheets for roofing offer several advantages, including durability, resistance to rust and corrosion, lightweight nature, and energy efficiency due to reflective properties. They are also easy to install and maintain, and can be recycled, making them environmentally friendly. However, there are some disadvantages such as being more expensive than some other roofing materials, potential for denting if not properly installed, and noise issues during heavy rain or hail due to their lightweight nature. Additionally, they may require more frequent replacement compared to some other materials.</p>

- Q: How much weight/people can a 12ft aluminum boat hold?and if anyone knows how much weight can a 6.5hp motor push around

- 12 Ft Aluminum Jon Boat

Send your message to us

Aluminum Trailer Siding Sheets - Coated Metal Aluminum Alloy Sheet from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords