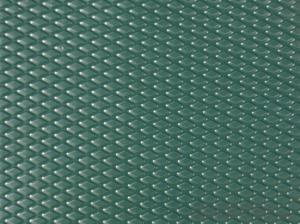

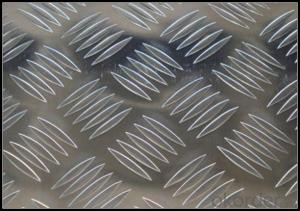

Aluminum Sheets in Kansas - Cold Rolled Stucco Embossed Aluminium Checker Plate 5 Bars

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Cold Rolled Stucco Embossed Aluminium Checker Plate 5 Bars

Description

Product | Aluminum sheet |

Country of Origin | China mainland |

Alloy | 7075 |

Temper | T6 |

Width | 200-1500mm |

Thinkness | 6-100mm |

Length | less than 8000mm |

MOQ | according to different size,normal 5 tons |

Payment Terms | T/T;L/C |

Loading Port | DaLian,Tianjing,Shanghai |

Delivery Time | Within 30 days after receiving the prepayment or original L/C |

Description

According to the composition of alloy, it can be divided into 5 items.

1) High purity aluminum plate (rolling by the content above 99.9 high purity aluminum)

2) Pure aluminum plate (rolled by pure aluminum)

3) Alloy aluminum plate (composition of aluminum and other alloy material, usually alu-copper, alu-manganese, alu-silicon, alu-magnesium, and so on)

4) Composite aluminum plate or brazing plate (made by a variety of composite materials)

5) Alclad aluminum (coated aluminium sheet outside of aluminium sheet used for special purposes)

According to the thickness, it can be divided into 4 items.

1) Thin plate (aluminum sheet) 0.15-2.0mm

2) The conventional plate (aluminum sheet) 2.0-6.0mm

3) Medium plate (aluminum plate) 6.0-25.0mm

4) Thick plate (aluminum plate) 25-200mm

5) More than 200 super- thick plate

FAQ

Q: How can I request a product sample? A: The samples are free but freight should be collected. Please send sample list and courier account number by email.

Q: How can I request a product catalog? A: The hard copies of catalogs are free but freight should be collected. Please send courier account number by email. You are suggested to request a PDF catalog.

Q: Wha's your payment terms? A: One is T/T 30% before production and 70% against copy of B/L; the other is Irrevocable L/C 100% at sight.

Q: What's your trade terms? A: FOB, CNF(CFR), CIF, EXW.

Q: How long is the quality guarantee? A: All of our products have a period of quality guarantee since time of shipment. Please contact your salesman for more details, as different products enjoy different time of guarantee

- Q: What is the thickness of an aluminum sheet?

- The thickness of an aluminum sheet can vary depending on its specific application and desired properties. Standard aluminum sheet thicknesses can range from 0.2 millimeters (0.008 inches) to several millimeters (0.1 inches or thicker).

- Q: What are the different methods of bending aluminum sheets?

- There are several methods of bending aluminum sheets, each with its own advantages and limitations. Some of the commonly used methods include: 1. Press Brake Bending: This method involves clamping the aluminum sheet between a punch and a die on a press brake machine. The sheet is then bent by applying force through the punch, which pushes against the die. Press brake bending is ideal for high-volume production and can achieve precise and consistent bends. 2. Roll Bending: Also known as a three-roll bending process, this method uses a set of three rollers to gradually bend the aluminum sheet into the desired shape. Roll bending is suitable for creating cylindrical or conical shapes and is often used in industries like automotive and aerospace. 3. Stretch Bending: In this method, the aluminum sheet is clamped at both ends while a stretching force is applied in the middle. The sheet is elongated and bent simultaneously, resulting in a curved shape. Stretch bending is commonly used for producing curved profiles with a smooth and uniform finish. 4. Heat Bending: By applying heat to the aluminum sheet, it becomes more pliable and can be easily bent into desired shapes. Heat bending is often performed using a heat gun or an oven to soften the metal, followed by manual or mechanical bending. This method is useful for creating complex and intricate shapes. 5. Incremental Bending: This method involves bending the aluminum sheet in multiple steps or increments, gradually increasing the bend angle with each step. Incremental bending allows for greater control over the bending process and is commonly used for forming U-shaped or V-shaped bends. 6. Roll Forming: In roll forming, the aluminum sheet is fed through a series of rollers, each gradually bending the sheet a little more. This continuous process is ideal for producing long and consistent bends, often used in the production of aluminum profiles and extrusions. It is worth noting that the choice of bending method depends on factors like the desired bend angle, the thickness and grade of the aluminum sheet, the required precision, and the volume of production.

- Q: Is it possible to utilize a custom-made door in place of a standard door within a construction or renovation project?

- <p>Yes, you can use a custom-made door to replace a standard door in your project. However, it's important to ensure that the custom door meets all the necessary building codes and specifications required for your project. This includes considerations for size, material, fire resistance, insulation, and any other relevant standards. Additionally, you should consult with your architect or contractor to confirm that the custom door will fit properly within the existing framework and align with the overall design and functionality of the space.</p>

- Q: Is it possible to use aluminum sheets as a material for the exterior walls of residential buildings?

- <p>Yes, aluminum sheets can be used for exterior walls in residential buildings. They offer several advantages such as durability, resistance to weather and corrosion, and low maintenance. Aluminum is lightweight, which can reduce structural load, and it can be easily shaped and installed. Additionally, it has good thermal performance and can be combined with insulation for energy efficiency. However, it's important to consider the aesthetic appeal, as aluminum may not match the traditional look of some residential buildings, and ensure it meets local building codes and standards.</p>

- Q: The idea that you can adequately protect yourself from the Alien and government thought transmissions with a 'tin-foil / aluminum hat is just a myth. The correct and real thing to use is an aluminum construction site type of hard-hat. That is why the government and all major defense contractors wore aluminum hard-hats back in the 1950's. The plastic and fiber glass hard-hats that they use now is only because the Aliens got wise to the old aluminum hard-hat trick and outlawed them after the Aliens and their Illuminati minions took over after President Truman got out of office. Everyone knows that.So does any company anywhere in the world currently defy the Alien’s production ban on aluminum hard hats? Or is e-bay and garage sales the only source of aluminum construction site hard hats?

- That's just what they want you to think. The aliens invented the myth that they have mind control and mind reading technologies to get ???г? you to buy more aluminum because they own 70% stock in all the companies that mine, process, manufacture, and recycle aluminum and aluminum products. By purchasing aluminum foil, aluminum hard hats, or any other aluminum products you are only making the Aliens wealthier and more capable of funding their eventual conquest of earth and its outlying territories.

- Q: What are the different heat treatment options available for aluminum sheets?

- Some of the different heat treatment options available for aluminum sheets include solution heat treatment, precipitation hardening, annealing, and stress relieving.

- Q: I found a baby dish at a yard sale and all it says on the bottom is Lydney Aluminum PRODUCTS FOR BETTER LIVING. It appears old. Thanks. I already checked google.

- Lydney Aluminum, I don't think that I have heard of them in the boating industry. T.

- Q: This question asks for signs or indicators that would suggest whether a roof needs to be replaced or repaired using aluminum sheets.

- <p>To determine if your roof needs replacement or repair with aluminum sheets, look for the following signs: visible rust or corrosion, especially on the seams and fasteners; sagging or buckling in the roof surface; leaks or water damage inside your home; and excessive noise during rain or wind. If the damage is widespread or the roof is old, replacement might be necessary. However, if the damage is limited to specific areas, repairs could suffice. It's always best to consult with a professional roofer for an accurate assessment.</p>

- Q: HEY HEY HEY guys its me agian and during today and the six week hoiday i'm gonna be askin a LOT I mean A-LOT ok so firstly I want to ask about drill bit you see as a willing studend who is enginenerring and just now in sience (so please ansewr quikly) what properites does an aluminium oxide drill bit have alot more questions after this one are going to be veary youtube and game related such as what do you guys want me to tweet pewdiepie on fridays whith pewdiepie and so on thanks and bye!!!!!!

- It acts a lubricant.

- Q: Are 101 aluminum sheets available in different finishes (e.g., brushed, polished)?

- Yes, 101 aluminum sheets are available in different finishes such as brushed and polished.

Send your message to us

Aluminum Sheets in Kansas - Cold Rolled Stucco Embossed Aluminium Checker Plate 5 Bars

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords