Aluminum Sheets for Aluminium Composite Panel Facade Decoration - Good Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Aluminium Composite Panel Facade Decoration Description:

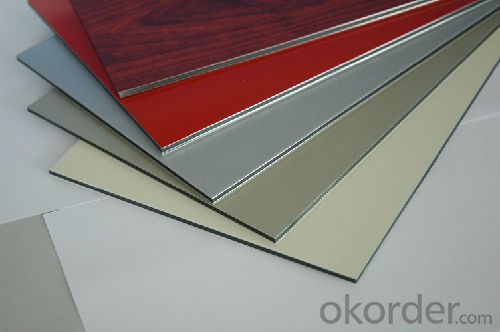

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of Aluminium Composite Panel Facade Decoration

Extremely strong agglutination

Excellent weather resistance

Excellent fire-retardant performance

Light and easy to machining, excellent impact resistance, easy to maintain

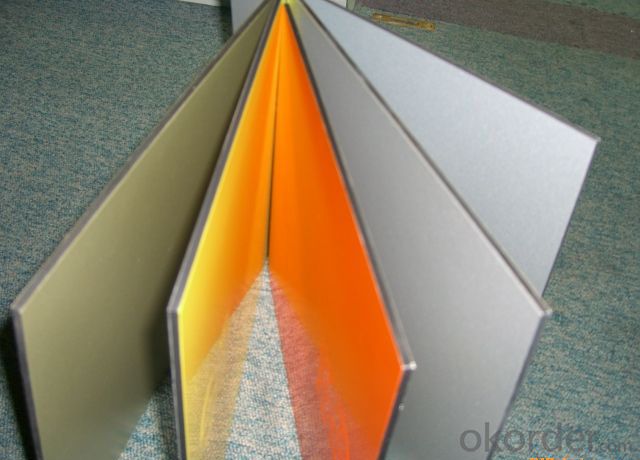

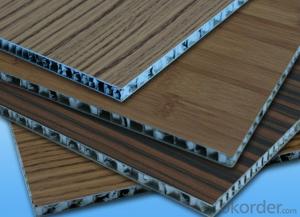

Coating : PVDF, PE, Granite-textured, Wood-textured, Mirror

Color: at your option. ( We could mix the color according to your reqirement.)

Surface and rear aluminum foil can be coating with fresh color as your requirement.

All of Aluminum foil is made from famous aluminum manufacture

In the middle is the no-toxicity Plastic core

PVDF coating can be effected for 15 years, and the PE coating can be effected for 8 years.

Images of Aluminium Composite Panel Facade Decoration

Aluminium Composite Panel Facade Decoration Specification:

| Specification | Recommend | |

| PVDF | 4*0.4mm | Most popular in the world for out door decoration |

| 4*0.5mm | Best for out door decoration in general | |

| 4*0.3mm | Economy also meet requirement for outdoor decoration | |

| 3*0.3mm | Popular for indoor decoration in commercial building | |

| 4*0.5mm Fireproof | Superior fireproof performance on the basis of the best specification | |

| PE | 3*0.3mm | Most popular in the world for indoor decoration |

| 3*0.21mm | Economy for indoor decoration in general | |

| Standard size | 1220*2440 and 1250*2440mm | |

| Accepted width | Max:1580mm | |

| Accepted length | Max:6000mm | |

| Accepted thickness | 2mm,3mm,4mm,5mm,6mm | |

| Aluminum alloy thickness | ACP thick | AL thick |

| 2mm | 0.06mm-0.15mm | |

| 3mm | 0.06mm-0.21mm | |

| 4mm | 0.06mm-0.55mm | |

| 5mm | 0.06mm-0.55mm | |

| Weight | 5kg/m2, based on 4*0.4mm,1400pcs/20'FCL | |

| Nonstandard | Sizes are available according your requirement | |

FAQ of Aluminium Composite Panel Facade Decoration

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 20000㎡.

b. Now which countries do you export your goods?

----Now we export to South East Asia,Africa, North America,South America ect.

A Brief Guide On Aluminum Sheets

Aluminum is the material of choice across a wide range of industries today. This metal is abundantly available, can be molded in different forms and shapes, and is more light-weight than steel. Of the different forms in which aluminum is used, sheeting is one of the most popular. In fact, you are sure to come across at least one object made of aluminum sheets every day. Whether you are in a car, traveling, or trying to open a can, or you switch on the electric bulb for a light read-chances are, all these things will contain some aluminum sheeting in them.

Sheets are formed when the aluminum block is passed between rolls under pressure. As it is rolled and re-rolled, it thins out and becomes longer in the direction in which it is moving. It becomes a sheet when the rolling process is stopped at 0.249 to 0.006 inch.

Sheets are made of different alloys so that they have the required amount of flexibility and toughness. They are graded accordingly. People then choose the variety on the use to which they will be put. Two of the most popular grades are 1100 for pure aluminum and 2011 for minor machine parts. For tougher, more durable materials, a grade of 5052 is suitable.

Many industries prefer aluminum for its wonderfully versatile and lightweight quality. The transportation industry has always loved this metal that improves fuel economy, cuts down emissions, and boosts vehicle performance. No wonder, then, that since 2006, aluminum has overtaken iron to become the second most used material in new vehicles across the world. Increasingly, car-makers are opting to become more eco-friendly by using aluminum sheets for the panels of car bodies. Other than this, bodies of planes use sheets made of this metal owing to their light-weird, robust quality.

Aluminum products are popular in households as well. A variety of objects used to build houses, such as flashing, siding, and roofs have aluminum sheets in them. Metal workers and artists also like this versatile material that can be made into furniture and art installations.

Aluminum sheets come in various qualities. The best quality is highly resistant to corrosion. Sometimes manufacturers provide customizing options depending on your need. Metalsforasteel is a great dealer that provides aluminum sheets in a variety of measurements. It also offers to discount prices for larger orders of 1000 pounds or more.

- Q: Explain the impact of aluminum sheets on the thermal insulation of a building.

- <p>Aluminum sheets, due to their high thermal conductivity, can significantly reduce the thermal insulation of a building. They allow heat to transfer easily through them, which can lead to increased heat loss in winter and heat gain in summer. This can result in higher energy consumption for heating and cooling, making the building less energy-efficient. However, when used in combination with proper insulation materials and techniques, aluminum sheets can still be part of an effective building envelope, provided their thermal bridging effects are mitigated.</p>

- Q: does anyone know how much aluminium is recycled per year worldwide compared to how much is produced? Even if you know the stats just for Australia or America it would helpthanksxx

- 45% The fact that they can be recycled to produce more cans means there is no excuse for many people to unaware of aluminum recycling. People should also be aware of the benefits that can occur from it. This has created a strong awareness of the recycling nature of cans and this has been a key factor in the growth of this area. In many canteens, dinner halls and corridors across schools and places of work there is a recycling bin. Wherever people can be found drinking from a soft drink can, a specific aluminum recycling bin can be found for cans to be placed in. Compared to the recycling of many other products, it is easier to find a recycle bin. The provisions for recycling soft drink cans have been more progressively tackled and many people are aware of the need to recycle soft drink cans. This has created awareness and knowledge about recycling and this has moved from school to the outside world. One of the major tactics of marketing departments is to target children and get them to pass the message through to all the family. This is usually done in a bad manner but it can also be done promote recycling. You may see people who go around picking up cans that are thrown away without thought and send them to a recycling center. There are some recycling centers that will make payment for numbers of soft drinks that are recycled. This is a way for people to make some money. It would take a phenomenal amount of aluminum recycling to make a fortune. However, it can help the environment and make a small amount of money back so many people can find the motivation to recycle. There are many places that could be a great source of finding soft drink cans that are thrown away: - School playgrounds - The beach - The car park - Parking lots - Busy streets The amount of products that are available to be recycled continues to grow but it is unlikely that they will grow to be more popular than aluminium recycling.

- Q: What are the necessary safety measures to be aware of when handling aluminum sheets?

- <p>When working with aluminum sheets, it's crucial to wear appropriate personal protective equipment (PPE), including gloves to prevent cuts and eye protection to shield against flying debris. Ensure good ventilation to avoid inhaling dust or fumes from cutting or polishing. Use sharp tools to minimize the risk of accidents and always cut away from your body. Keep the work area clean and free of clutter to prevent slips or trips. Be cautious of electrical hazards if using power tools, and ensure all tools are properly grounded. Finally, be aware of the fire hazard potential of aluminum dust and store it safely away from ignition sources.</p>

- Q: And isn't aluminum extremely bad for ones health?

- it's okorder

- Q: Are aluminum sheets suitable for reflective signage?

- Indeed, reflective signage can effectively utilize aluminum sheets. This adaptable material is frequently employed for such signs because of its resilience, lightness, and capacity to reflect light. With a noteworthy reflectivity index, aluminum proves itself ideal for situations where visibility is of utmost importance, such as road signs, traffic signs, and safety signs. By applying reflective films or paints to aluminum sheets, their reflective properties can be further enhanced, guaranteeing optimal visibility even in dimly lit environments. Furthermore, aluminum's resistance to weathering, corrosion, and fading ensures that it remains a durable and economical option for reflective signage in the long run.

- Q: Is this aluminium plate ceiling dark keel or bright keel?

- I see you're a layman...... Where is the ceiling keel now?.... Now they are made of dark keel, so it's better to look at comfort, and we need to go through the lines and some pipes

- Q: Are the aluminum sheets suitable for manufacturing solar panel backings?

- Aluminum sheets, indeed, prove to be a fitting choice for the production of solar panel backings. With its exceptional properties, aluminum has gained significant popularity in the solar industry. Its lightweight nature, durability, and resistance to corrosion make it highly suitable for outdoor applications. Furthermore, aluminum exhibits a remarkable ability to conduct heat effectively, a critical factor for ensuring the efficient operation of solar panels. Moreover, the recyclability of aluminum makes it an environmentally conscious option for solar panel manufacturing. All in all, aluminum sheets serve as an appropriate material for the fabrication of solar panel backings.

- Q: Are aluminum sheets suitable for use in cryogenic environments?

- Yes, aluminum sheets are suitable for use in cryogenic environments. Aluminum has excellent thermal conductivity, low density, and good mechanical properties at low temperatures, making it an ideal choice for applications in cryogenic environments. Additionally, aluminum has a low coefficient of thermal expansion, which allows it to maintain its structural integrity even under extreme temperature fluctuations.

- Q: How are aluminum sheets cut or shaped?

- Aluminum sheets can be cut or shaped using various methods depending on the desired outcome. One common method is using a saw, such as a circular saw or a bandsaw, with a carbide-tipped blade specifically designed for cutting metal. This allows for straight cuts and can be used for both thin and thick aluminum sheets. Another method is using a shear, which is a machine that uses sharp blades to cut the aluminum sheet. Shearing is ideal for cutting straight lines quickly and efficiently, especially for thinner sheets. For more intricate shapes or curves, aluminum sheets can be cut using a water jet cutter or a laser cutter. Water jet cutting involves using a high-pressure jet of water mixed with an abrasive material to cut through the sheet. Laser cutting, on the other hand, uses a focused laser beam to melt or vaporize the aluminum, resulting in precise and intricate cuts. In addition to cutting, aluminum sheets can also be shaped through processes like bending, rolling, or stamping. Bending involves using a press brake to bend the sheet into the desired angle or shape. Rolling, on the other hand, uses a rolling machine to gradually shape the sheet into curves or cylinders. Lastly, stamping involves pressing the sheet against a die to create specific shapes or patterns. Overall, the method used to cut or shape aluminum sheets depends on the thickness of the sheet, the desired outcome, and the available equipment.

- Q: What is the weight of aluminum sheets?

- The weight of aluminum sheets can vary depending on their thickness and dimensions. However, on average, aluminum sheets typically weigh around 2.7 grams per cubic centimeter.

Send your message to us

Aluminum Sheets for Aluminium Composite Panel Facade Decoration - Good Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords