Sign Aluminum Sheets for Aluminium Composite Panel Facade Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

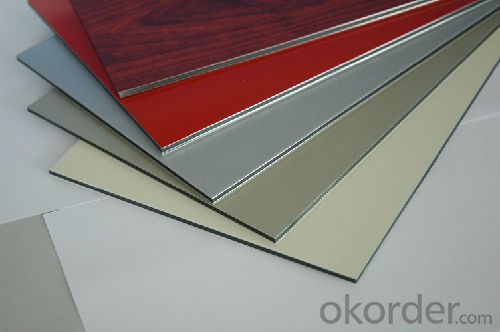

Structure of Aluminium Composite Panel Facade Decoration Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of Aluminium Composite Panel Facade Decoration

Extremely strong agglutination

Excellent weather resistance

Excellent fire-retardant performance

Light and easy to machining, excellent impact resistance, easy to maintain

Coating : PVDF, PE, Granite-textured, Wood-textured, Mirror

Color: at your option. ( We could mix the color according to your reqirement.)

Surface and rear aluminum foil can be coating with fresh color as your requirement.

All of Aluminum foil is made from famous aluminum manufacture

In the middle is the no-toxicity Plastic core

PVDF coating can be effected for 15 years, and the PE coating can be effected for 8 years.

Images of Aluminium Composite Panel Facade Decoration

Aluminium Composite Panel Facade Decoration Specification:

| Specification | Recommend | |

| PVDF | 4*0.4mm | Most popular in the world for out door decoration |

| 4*0.5mm | Best for out door decoration in general | |

| 4*0.3mm | Economy also meet requirement for outdoor decoration | |

| 3*0.3mm | Popular for indoor decoration in commercial building | |

| 4*0.5mm Fireproof | Superior fireproof performance on the basis of the best specification | |

| PE | 3*0.3mm | Most popular in the world for indoor decoration |

| 3*0.21mm | Economy for indoor decoration in general | |

| Standard size | 1220*2440 and 1250*2440mm | |

| Accepted width | Max:1580mm | |

| Accepted length | Max:6000mm | |

| Accepted thickness | 2mm,3mm,4mm,5mm,6mm | |

| Aluminum alloy thickness | ACP thick | AL thick |

| 2mm | 0.06mm-0.15mm | |

| 3mm | 0.06mm-0.21mm | |

| 4mm | 0.06mm-0.55mm | |

| 5mm | 0.06mm-0.55mm | |

| Weight | 5kg/m2, based on 4*0.4mm,1400pcs/20'FCL | |

| Nonstandard | Sizes are available according your requirement | |

FAQ of Aluminium Composite Panel Facade Decoration

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 20000㎡.

b. Now which countries do you export your goods?

----Now we export to South East Asia,Africa, North America,South America ect.

- Q: What are the advantages of using aluminum sheets compared to other materials?

- There are several advantages of using aluminum sheets compared to other materials. First, aluminum is lightweight, making it easier to handle and transport. Second, aluminum has corrosion resistance properties, ensuring durability and longevity. Third, aluminum sheets can be easily formed and molded into various shapes, allowing for versatility in applications. Additionally, aluminum is a good conductor of heat and electricity, making it suitable for use in industries such as aerospace and electrical engineering. Lastly, aluminum is recyclable, making it an environmentally friendly choice.

- Q: Can aluminum sheets be used for heat sinks?

- Indeed, heat sinks can utilize aluminum sheets. Due to its outstanding thermal conductivity, aluminum serves as an ideal substance for efficiently diverting heat away from electronic parts. With the ability to be fashioned into different dimensions and configurations, aluminum sheets can optimize the dispersion of heat. They find widespread employment in computer processors, LED lights, and power electronics, where the preservation of peak performance and the prevention of overheating hinge on effective heat dissipation. Moreover, the lightweight nature and cost-effectiveness of aluminum sheets render them highly favored for heat sink purposes.

- Q: How do you ensure the surface quality of aluminum sheets?

- To guarantee the surface quality of aluminum sheets, manufacturers can take several steps: 1. Cleanliness is crucial. Prior to any surface treatment or inspection, it is vital to thoroughly clean the aluminum sheets and eliminate any dirt, grease, or contaminants. This can be accomplished using solvents, detergents, or specialized cleaning agents. 2. A visual inspection is necessary. Trained personnel should visually inspect the surface for visible flaws such as scratches, dents, or pitting. Proper lighting and magnification tools should be utilized. 3. Chemical treatments may be required. Depending on the desired surface finish and application, aluminum sheets may undergo chemical treatments such as anodizing, chromate conversion coating, or passivation. These processes can enhance the sheets' surface quality, corrosion resistance, and aesthetic appearance. 4. Mechanical polishing can be employed. To eliminate surface imperfections and achieve a smooth, glossy finish, mechanical polishing techniques like grinding, buffing, or sanding can be utilized. It is important to maintain consistency and avoid over-polishing, which can compromise the integrity of the sheets. 5. Coating and protection are essential. Applying protective coatings like lacquers, paints, or powder coatings can further improve the surface quality, appearance, and durability of aluminum sheets. These coatings act as a barrier against corrosion, abrasion, and environmental factors. 6. Quality control is crucial. Rigorous quality control procedures should be implemented throughout the manufacturing process. Regular inspections, testing, and documentation should be conducted to ensure that the surface quality of aluminum sheets meets the required standards and specifications. 7. Proper handling and packaging are necessary. To prevent surface damage during transportation and storage, it is important to handle and package the sheets correctly. Protective measures such as using protective films, paper interleaves, or cushioning materials should be employed to safeguard the surface quality until the sheets reach their final destination. By following these measures, manufacturers can ensure that the surface quality of aluminum sheets meets the desired specifications and exceeds customer expectations.

- Q: How much is one ton of aluminium plate?

- Look at the material of the aluminum sheet about 18 better T6, about 20 to almost 5052 in 25 some brands will be more expensive to buy and then also need to invoice invoice must the seller will give you points plus tax needed to contact

- Q: This question asks for methods to determine if a building is utilizing high-quality aluminum sheets.

- <p>To determine if a building is using high-quality aluminum sheets, look for the following characteristics: the sheets should have a uniform and smooth surface without visible defects or impurities. Check for a strong and consistent thickness throughout the material. High-quality aluminum is also resistant to corrosion and should not show signs of rust or pitting. Additionally, the sheets should be lightweight yet rigid, indicating a high strength-to-weight ratio. You can also inquire about the manufacturer's specifications and certifications, as reputable suppliers will provide detailed information about the quality and composition of their aluminum sheets.</p>

- Q: which has more volume? a kg of gold or a kg of aluminum? please explain in physics terms

- Aluminum The density of Aluminum is pretty low. Gold has a very high density, almost twice as dense as iron. Density = mass / volume

- Q: I'm about to fix the aluminum wiring in my house using Alumiconn connection, so I know that every outlet and switch plate need to be done, do the light fixtures need to be done as well? And also does anything need to be done with the main circuit breaker?

- Anywhere you have a tap the new method should be done. The kitchen outlets that draw more amps usually have the biggest problem but with vacuum cleaners that draw about 10 or 12 amps all outlets are a problem. The wires should be taken off all outlets and tapped to a short copper wire with approved method and the the copper wire is put to the outlets and also switches. All taps have to use the right type of paste and right crimps and or wire nuts. The main breaker if alum wire should be taken off wire brushed and have the right type of Penetrox paste put on wires and put back. If the breaker can fit one of those crimp ends you put on alum wire and insert in breaker better yet. I did one house years ago and it is a job. I was able to fish new copper wire to all the kitchen outlets all the way back to panel.

- Q: What are the different methods of surface cleaning for aluminum sheets?

- Aluminum sheets can be cleaned using various methods, each with its own advantages and suitability for different cleaning needs. One method is mechanical cleaning, which involves using techniques like brushes, abrasive pads, sandpaper, or a wire brush to remove dirt, stains, and oxidation from the surface. However, caution must be taken to avoid scratching the surface. Chemical cleaning, on the other hand, utilizes specific cleaning agents or solutions designed to dissolve or remove dirt, grease, oil, or other contaminants from aluminum surfaces. The choice of cleaning agent depends on the type of dirt or stain to be removed. High-pressure water cleaning is a method that employs a strong water jet to dislodge dirt or grime from the aluminum surface. It works well for removing loose debris or light dirt from larger areas, but may not be effective for heavily soiled surfaces. Steam cleaning involves using high-temperature steam to loosen dirt, grime, or other contaminants, making them easier to wipe or rinse away. It is versatile and suitable for both small and large surfaces. Another specialized method is electrolytic cleaning, which uses an electric current to remove contaminants. The aluminum sheet is immersed in a cleaning solution, and the electric current attracts the contaminants to a sacrificial electrode, leaving the sheet clean. However, this method requires specialized equipment and expertise. When choosing the appropriate cleaning method, it is important to consider the specific requirements, condition of the sheet, and desired level of cleanliness. Testing the chosen method on a small, inconspicuous area is also advisable to avoid potential damage.

- Q: How do aluminum sheets perform in high-temperature environments?

- Aluminum sheets perform well in high-temperature environments due to their excellent thermal conductivity and low melting point. Aluminum has a melting point of 660.3°C (1220.5°F), which is relatively low compared to other metals, allowing it to withstand high temperatures without melting. Additionally, aluminum has a high thermal conductivity, meaning it can effectively transfer heat away from the surface, preventing overheating and maintaining structural integrity. This characteristic makes aluminum sheets suitable for applications in industries such as aerospace, automotive, and construction, where high temperatures are encountered. However, it is important to note that prolonged exposure to extremely high temperatures can cause aluminum to weaken and lose some of its mechanical properties. Therefore, in extremely high-temperature environments, it may be necessary to consider alternative materials or use additional protective measures to ensure optimal performance.

- Q: I am ultimately looking to have a bike that is good for both everday commuting and touring with panniers/racks long distance with camping. From what I've read on the internet steel frames are more forgiving and ride smoother. The guy at my local bike shop tells me aluminum frames have more flex and ride better. I don't know if he's just trying to make a sale (Giant dealer) or to trust him, unfortunately the staff there are all just racers not tourers. If you can recommend any brands/models to check out that'd be good. From my research thus far I am in love with Co Motion bikes, just not the price! I'm looking at $1000 max for a good touring bike. Thanks!

- looks like the Americano series are equipped with tandem wheelset. That's heavy duty touring. I believe he is trying to make a sale. If aluminum flexes, then the result will be a crack. If steel decide to fail, it bends from fatigue, aluminum just snaps when it fails. Steel gives you a much noticeable warning. So...steel bends. It flexes when you put a lot of stress, but when you are touring, it's not likely your going to go all out like racers do when they pursue. Steel will absorb more of the road vibrations and shock. You might want to try a different shop if all they do is pitch Giant brand. BTW Giant is THE world largest bicycle manufacturer. They build bikes for different companies besides their own. So you never know where or what brand your really riding. There are many touring bikes out, but if you go by manufacturers then it is only limited to a few by brands. There is more options when you want a racer. Remember when choosing a touring bike to choose one with a good wheelset. I like wheels with 36 spokes or more, they take the brunt of the weight (rack, pannier, other accessories).

Send your message to us

Sign Aluminum Sheets for Aluminium Composite Panel Facade Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords