Aluminum Sheets Connecticut - Aluminium Plain Sheets 1100 for Bus Body

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Plain Sheets 1100 for Bus Body Description:

We can produce aluminum sheet,color aluminum sheet and plastic composite panel base material. They are widely used in construction and decoration, hardware and electric appliances manufacture, automobile manufacture and other industrial and civil purposes, such as electronic capacitor, rice cooker, refrigerator, computer casting, lamp shade, air-conditioner, cosmetics cover and box, air-conditioner radiator, inner container of disinfecting cabinet, ceiling board, automobile motherboard, cover board and top board, etc.

2.Main Features of Aluminium Plain Sheets 1100 for Bus Body :

Good Corrosion Resistance

No scratches, white corrosion

High Quality

Competitive Price

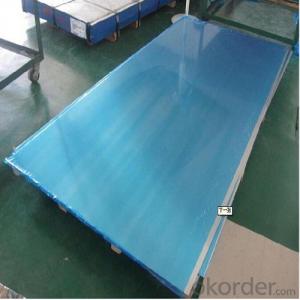

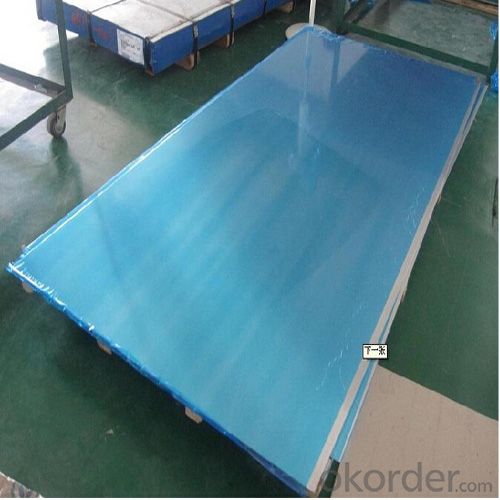

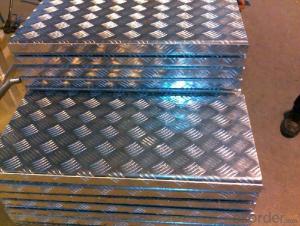

3. Aluminium Plain Sheets 1100 for Bus Body Images:

4. Aluminium Plain Sheets 1100 for Bus Body Specification:

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Is it possible to use aluminum sheets as a material for flooring?

- <p>Yes, aluminum sheets can be used for flooring applications. They are known for their durability, resistance to corrosion, and ease of maintenance, making them suitable for various environments. Aluminum flooring is often used in commercial, industrial, and residential settings due to its strength and lightweight nature. It can be found in applications such as walkways, ramps, and as a covering for platforms. However, it's important to note that aluminum may not be the best choice for all flooring needs, especially where thermal insulation or a softer, warmer feel is desired.</p>

- Q: AND WAT R THE THECNOLOGICAL ANDCOSTS AND BENEFITESOF USING ALUMINUM? what health -related and environment-related issues gave surface as aresult of its widespread use in society?

- airplanes are made from aluminum. certain beverages are also. aluminum is cheaper and lighter. the biggest problem is the amount of electricity that it takes to make aluminum

- Q: Are aluminum sheets easy to clean?

- Yes, aluminum sheets are generally easy to clean due to their smooth surface and non-porous nature, allowing for easy removal of dirt, grease, and stains with regular cleaning agents.

- Q: What is the typical shear strength of aluminum sheets?

- The typical shear strength of aluminum sheets can vary depending on various factors such as the alloy, temper, thickness, and manufacturing process. However, for most common aluminum alloys, the typical shear strength falls within the range of 207 to 310 megapascals (MPa) or 30,000 to 45,000 pounds per square inch (psi). It is important to note that these values are just general guidelines and there can be variations depending on the specific application and conditions. For critical applications, it is recommended to consult the material specifications or seek professional advice to determine the precise shear strength requirements for the specific aluminum sheet being used.

- Q: This question asks about the key factors to consider when buying aluminum sheets, including material properties, thickness, surface finish, and other relevant details.

- <p>When purchasing aluminum sheets, consider the following specifications: 1) Alloy type, which determines properties like strength and corrosion resistance; 2) Thickness, measured in millimeters, affecting the sheet's durability and application; 3) Width and length, which should match your project requirements; 4) Surface finish, such as mill finish, anodized, or painted, which impacts aesthetics and protection; 5) Temper, indicating the hardness and formability of the sheet; 6) Certifications, ensuring the sheet meets industry standards; 7) Supplier reputation and customer reviews for quality assurance. These factors will help you select the right aluminum sheet for your specific needs.</p>

- Q: Are aluminum sheets suitable for aerospace structural components?

- Yes, aluminum sheets are suitable for aerospace structural components. Aluminum is a lightweight and durable material that has been widely used in the aerospace industry for many years. It possesses excellent strength-to-weight ratio, making it highly desirable for various applications in aircraft manufacturing. Aluminum sheets offer several advantages for aerospace structural components. Firstly, they are lightweight, which helps reduce the overall weight of the aircraft. This is crucial for improving fuel efficiency, increasing payload capacity, and enhancing the performance of the aircraft. Additionally, the lightweight nature of aluminum sheets allows for easier handling and assembly during the manufacturing process. Secondly, aluminum has excellent corrosion resistance properties. This is crucial for aerospace applications as the components are exposed to various environmental conditions, such as high humidity, extreme temperatures, and exposure to chemicals. The corrosion resistance of aluminum ensures the longevity and durability of the structural components, reducing the need for frequent maintenance and replacement. Furthermore, aluminum is a highly malleable material, allowing for easy shaping and forming into complex structures. It can be easily bent, cut, and fabricated to meet specific design requirements, making it versatile for various aerospace applications. The ability to form complex shapes with aluminum sheets enables engineers to design efficient and streamlined structures, optimizing aerodynamics and minimizing drag. Another advantage of aluminum sheets is their excellent thermal conductivity. This property allows for efficient heat dissipation, which is crucial in aerospace applications where components may be exposed to high temperatures generated during flight or engine operation. The thermal conductivity of aluminum helps prevent overheating and ensures the structural integrity of the components. In conclusion, aluminum sheets are highly suitable for aerospace structural components due to their lightweight, corrosion resistance, malleability, and thermal conductivity properties. These characteristics make aluminum an ideal material for various applications in the aerospace industry, contributing to the overall performance, efficiency, and safety of aircraft.

- Q: Can aluminum sheets be used for cryogenic applications?

- Aluminum sheets are indeed applicable for cryogenic purposes. Their suitability arises from their commendable thermal conductivity and low density. These qualities enable them to endure exceedingly low temperatures without succumbing to brittleness or compromising their mechanical attributes. Furthermore, aluminum exhibits non-magnetic properties and exceptional resistance to corrosion, rendering it highly significant in cryogenic applications. Nevertheless, it is crucial to meticulously choose the appropriate alloy and thickness of the aluminum sheet, considering the precise cryogenic temperature and intended use, to guarantee optimal performance.

- Q: Can aluminum sheets be used for fencing?

- Yes, aluminum sheets can be used for fencing. Aluminum is a lightweight and durable material, making it suitable for fencing purposes. It is resistant to rust and corrosion, making it a long-lasting option. Additionally, aluminum sheets offer a sleek and modern look to any fence.

- Q: Can the aluminum sheets be used for architectural cladding?

- Yes, aluminum sheets can be used for architectural cladding.

- Q: This question asks about the various surface treatments or finishes that can be applied to custom-made aluminum sheets.

- <p>Custom-made aluminum sheets can be finished in a variety of ways to achieve different aesthetic and functional properties. Some of the common finishes include: Anodizing, which provides a protective oxide layer and can be colored; Powder coating, offering a durable and colorful finish; Mill finish, which is the natural surface of the aluminum after rolling; Brushed or Satin finish, giving a鍝戝厜 texture; Mirror finish, providing a reflective, polished surface; and Painted finish, where the aluminum is coated with a layer of paint for color and protection. Each finish serves different purposes, from enhancing corrosion resistance to improving the visual appeal of the aluminum sheet.</p>

Send your message to us

Aluminum Sheets Connecticut - Aluminium Plain Sheets 1100 for Bus Body

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords