6061 Aluminum Sheets 5-Pack 0.081 - Aluminum Sheet for Pattern Diamond in 5 Liners or 3 Liners

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.specification

material: | Alloy or not | ||

thickness: | 1,3 series | 0.3-9.5mm | |

5series | 0.5-150mm | ||

6 series | 5-150mm | ||

7series | More than 6mm | ||

width: | 1,3 series | 900-1500mm | |

5 series | 900-1500mm | ||

6 ,7series | As your request | ||

Circulation size: (width*length)

| 1220*2440mm 1250*2500mm 1500*3000mm 1000*2000mm | ||

Usage : | Boat, plane, building, packaging, machine…. | ||

MOQ | 3 tons | ||

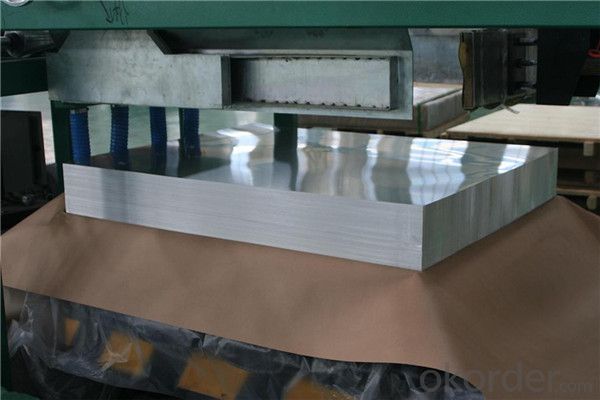

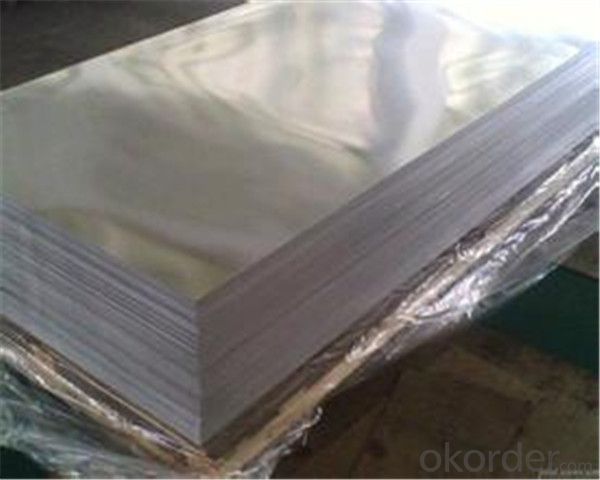

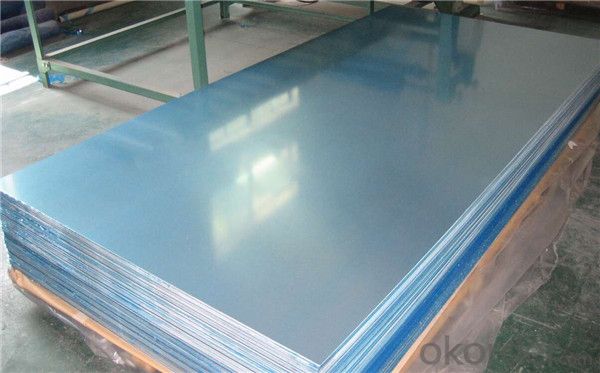

2.product show

Dear Customer, why do I have the confidence to let you buy our product ?

♥strict chemical composition , good hardness high safety performance

♥Oxide film thickness, corrosion resistance

♥Standard aluminum closed time, no rust

♥smooth surface, no burrs

Our VS others

3.shipping:

20~25 working days & send samples:2--3 days after received your advance payment

Mode of transport | advantage | disadvantage | advice |

Express delivery | Fast(3—6days ),door to door wide area coverage | Volume & weight restricted | Good for small cargo |

Sea transpoet | Cheapest volume unlimited | Long sailing time influenced by climate and port conditions | Bulk cargo loose time |

Air transport | Fast(4—5days) simple packaging | The most expensive volume restrict | For valuable cargo urgent need |

Railway | Big volume more expensive | Tracking difficult transit organization may cause delay | Preferred in central Asia |

4.Product photos

- Q: Can aluminum sheets be used for boat hulls?

- Yes, aluminum sheets can be used for boat hulls. Aluminum is a popular material choice for boat hulls due to its lightweight nature, high strength-to-weight ratio, and excellent corrosion resistance. Aluminum sheets are often used in boat construction to create hulls that are durable, sturdy, and capable of withstanding harsh marine environments. The versatility of aluminum allows for various fabrication techniques, making it suitable for different types of boats, including recreational boats, fishing boats, and even commercial vessels. Moreover, aluminum hulls require less maintenance compared to other materials, which makes them a cost-effective option for boat owners.

- Q: Can aluminum sheets be bent into complex shapes?

- Yes, aluminum sheets can be bent into complex shapes due to their malleability and ductility. With the appropriate tools and techniques, aluminum sheets can be formed into intricate and customized designs, making them versatile for various applications.

- Q: Can aluminum sheets be embossed or textured?

- Aluminum sheets are indeed capable of being embossed or textured. To achieve this, specialized machinery is employed to press or roll the sheet, thereby creating patterns or designs on its surface. The purpose of embossing or texturing aluminum sheets can be twofold: enhancing the sheet's aesthetic appeal or enhancing its functionality by providing grip or augmenting its strength. These embossed or textured aluminum sheets find widespread usage across different industries, including automotive, interior design, and packaging.

- Q: Curtain wall aluminum plate reinforcement spacing between the number of appropriate, the country has no standard?

- As to the stiffener of the aluminum veneer, what are the following points?:1, aluminum reinforcement spacing is generally around 600mm, in order to ensure the aluminum plate in the positive and negative pressure conditions within the scope of deformation. When aluminum plate is welded, there is internal stress due to welding deformation (this internal stress can not be completely eliminated for a long time), and the rigidity of reinforcing bar should also be increased.2. The sectional dimension and spacing of stiffeners shall be determined according to the calculated wind pressure of the aluminum plate. But it is worth noting that the reinforcement calculation of single aluminum plate strengthening is different from the glass curtain wall, first, its strength is certainly no problem (still not seen the wind blowing broken plate, there is no joke) deflection possibility, bend off and windy weather also very few people to pay attention to the single aluminum plate plate surface after deformation the scenery. Therefore, the calculation of deflection of stiffeners are considered under the condition of wind strength and deflection when the winds of aluminum can cause permanent plastic deformation.In fact, aluminum veneer manufacturers generally use the single aluminum plate edge folding groove made of aluminum and 20*40*20, installed in the distance about 600mm. Also useful for profile (grooved aluminum) stiffenersThe spacing between stiffeners is very important to the cost of production. Generally speaking, the spacing of stiffeners will be changed from 600 to 350, and the cost will be increased by 8~15 yuan / square meter

- Q: my grandpa gave me a family harloom, a 1971 Honda Trail 90, after it sat in a shed for a good 30 years. i have got most everything in tip top shape except for the polished aluminum has become lightly tarnished. and because i am a perfectionist

- You can use furniture stripper to dissolve the clear-coat. Then you can polish up the parts using Simichrome or other chrome polish. Then spray on a new clear-coat. I used a Harley-Davidson product in the past (on a Honda) with very good results. Note that you may get a finish which is actually glossier than the original Honda finish. You may prefer that, or you may be more interested in replicating the original finish. It all depends on what you want, and how far you go with the polishing. In my case, I ended up having the parts professionally triple chrome plated several years later for a really custom look (once I had the money to do it). BTW, your cases are made of an aluminum alloy. Apparently, pure aluminum does not tarnish, but is not considered strong enough.

- Q: i want to build a smelter to recycle aluminum auto parts

- It requires high temperature (933K), and is inefficient for small quantities. Why not just sell it to your local recycler?

- Q: This question asks about the structural integrity and suitability of aluminum sheets for use in the construction of high-rise buildings.

- <p>Aluminum sheets are not typically used as the primary structural material in high-rise buildings due to their lower strength compared to steel and concrete. However, aluminum is known for its high strength-to-weight ratio, making it suitable for non-structural applications such as facades, window frames, and roofing. In high-rise construction, aluminum can be used in combination with other materials to provide a lightweight and aesthetically pleasing exterior while maintaining structural integrity with stronger materials like steel and concrete.</p>

- Q: Can the aluminum sheets be used in the construction industry?

- Yes, aluminum sheets can be used in the construction industry. Aluminum is lightweight, corrosion-resistant, and has high strength-to-weight ratio, making it suitable for various construction applications such as roofing, cladding, windows, and doors.

- Q: I have seen some stainless steel rifles that you can basically dunk in water, require no cleaning, etc and perform time after time. If SS is so good why are most weapons made of aluminum parts which is then anodized coated black? If you dunk these weapons in water will they rust? Thanks

- Stainless steel will rust.. It does have small amounts of carbon in it It just takes longer... Than carbon steel to stain Aluminum works for low stress parts ... AR lowers, hand gun frames If the part is stressed or needs wear resistance it generally is made of tool or ordinance grade steel-carbon or stainless

- Q: What are the different methods of surface passivation for aluminum sheets?

- There are several different methods of surface passivation for aluminum sheets, each with its own advantages and applications. Some of the commonly used methods include anodizing, chromate conversion coating, and organic coating. 1. Anodizing: Anodizing is a widely used method that involves creating a thick protective oxide layer on the surface of the aluminum sheet. This is achieved by immersing the sheet in an electrolyte solution and passing a current through it. Anodizing provides excellent corrosion resistance, improves the surface hardness, and allows for various color options through dyeing. It is commonly used in architectural and decorative applications. 2. Chromate conversion coating: Chromate conversion coating, also known as chemical conversion coating or chromating, involves treating the aluminum surface with a solution containing chromate compounds. This method provides a thin, protective layer that improves corrosion resistance and enhances paint adhesion. It is widely used in aerospace, automotive, and electronics industries. 3. Organic coating: Organic coating refers to the application of a protective layer of organic material, such as paint or powder coating, onto the aluminum surface. This method provides exceptional corrosion resistance and can also offer aesthetic options. Organic coating is commonly used in industries where the aluminum sheets are exposed to harsh environments or require specific colors or finishes. 4. Plasma electrolytic oxidation (PEO): PEO is a relatively newer method that involves immersing the aluminum sheet in an electrolyte solution and passing high-voltage current through it. This process leads to the formation of a ceramic-like oxide layer on the surface, which enhances corrosion resistance, hardness, and wear resistance. PEO is commonly used in applications requiring high-performance coatings, such as aerospace and automotive industries. 5. Passivation with acids or chemicals: Passivation using acids or chemicals involves treating the aluminum surface with a solution that removes impurities and forms a protective layer. This method helps in reducing the reactivity of the surface and enhances corrosion resistance. It is commonly used in industrial applications where aluminum sheets are exposed to harsh chemicals or environments. Overall, the choice of surface passivation method for aluminum sheets depends on the specific requirements of the application, such as corrosion resistance, aesthetics, hardness, and environmental factors. It is important to consider factors such as cost, durability, and the desired performance characteristics when selecting the appropriate method.

Send your message to us

6061 Aluminum Sheets 5-Pack 0.081 - Aluminum Sheet for Pattern Diamond in 5 Liners or 3 Liners

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords