Aluminum Sheet 2024 for Aircraft rids Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminum Sheet 2024 for Aircraft rids Use

l Production Introduction

CHEMICAL COMPOSITION LIMITS (WT.%)

Si . . . 0.50 Zn . . . . . . . . . 0.25

Fe. . . 0.50 Ti . . . . . . . . . . 0.15

Cu . . 3.8-4.9 Others, each . . 0.05

Mn . . 0.30-0.9 Others, total . . 0.15

Mg . . 1.2-1.8 Balance, Aluminum

Cr. . . 0.10

Note: Value maximum if range not shown.

Temper: T3,T4,T351,T851

Thickness: 1.0-100mm

Width: 30mm-1500mm

Lenght: under 10000mm

Material: CC or DC (continue casting or hot rolled)

Packing: In standard seaworthy export wooden cases.

Application: It is widely use for aircraft structure, rivets, missile components, truck hub, screw components and a variety of other structures.

Certificate: FDA,SGS,Military product certificate, ISO9001:2000. ISO14001:2004

Standard: ASTM B 209-1996 .GB/T 3880-2006

l Packaging & Delivery

Packaging detail: Standard export packing, wooden cases with plastic protection for sheets or as customers' requirement.

Delivery detail: Within 25days

l Company Profile

CNBM, China National Building Material Group Corporation is the largest state owned company under central government of China that deals with building materials and industrial equipment.

Since 1984, we are professional manufacturer of construction machinery and equipment with the brand CMAX. Here I recommend our Aluminium Treadplate to you.

We have our own factory, logistics system, e-business platform, and oversea warehouse. Our products meet international quality standard, with CE certificate.

l CNBM World Wide

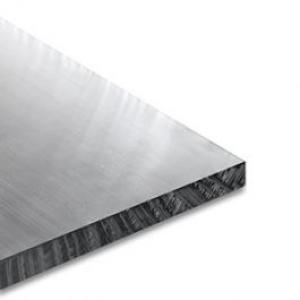

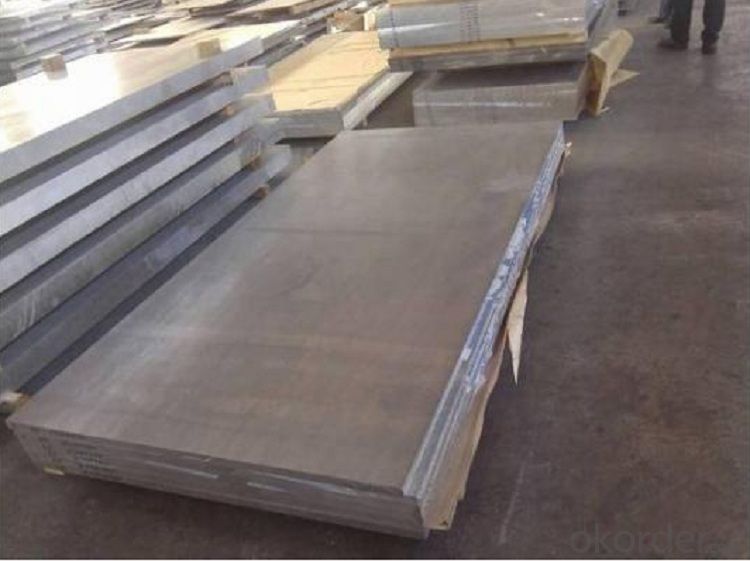

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons per size

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: What specific criteria or standards must be met when utilizing recycled aluminum in construction?

- <p>Recycled aluminum products used in construction projects must meet specific requirements to ensure safety, durability, and compliance with building codes. These include adherence to ASTM standards for recycled aluminum alloys, such as ASTM B601 for ingots and ASTM B209 for rolled or cold finished products. The recycled aluminum must also have consistent mechanical properties and corrosion resistance comparable to virgin aluminum. Additionally, the products should be free from contaminants that could compromise structural integrity. It's crucial to verify the source and processing methods of recycled aluminum to ensure it meets these standards before use in construction.</p>

- Q: The minimum thickness of aluminum curtain wall is 2, 5mm or 3mm?

- The conventional design of single aluminum plate is up to 2.5 mm, the other I still haven't met,

- Q: Can aluminum sheets be used for packaging?

- Yes, aluminum sheets can be used for packaging. Aluminum is a versatile and widely used material in the packaging industry due to its numerous advantageous properties. It is lightweight, strong, durable, and resistant to corrosion, making it an ideal choice for packaging applications. Aluminum sheets can be easily formed into various shapes and sizes, providing flexibility in design and customization. Additionally, aluminum is impermeable to light, moisture, gases, and microorganisms, ensuring the preservation and protection of the packaged goods. It is also a good conductor of heat, which allows for efficient heat transfer during processes like sterilization or pasteurization. Furthermore, aluminum is recyclable, making it an environmentally friendly packaging option. Overall, aluminum sheets are an excellent choice for packaging due to their excellent properties and versatility.

- Q: 5052 can aluminum plate be machined with laser cutting machine?

- Can cut, but the incision does have cut marks, if processing 3 mm below the thickness, incision quality will be better.

- Q: What are the safety concerns to be aware of when handling aluminum sheets?

- <p>When working with aluminum sheets, there are a few safety concerns to consider. First, aluminum dust can be a respiratory hazard, so it's important to use proper ventilation and personal protective equipment like masks. Second, sharp edges can cause cuts; always handle aluminum sheets with gloves and proper tools. Additionally, aluminum is a good conductor of electricity, so avoid contact with live electrical wires. Lastly, when cutting or shaping aluminum, eye protection is crucial due to the risk of flying debris. Always follow safety guidelines specific to your workplace and the tools you are using.</p>

- Q: Are aluminum sheets prone to warping?

- Yes, aluminum sheets are prone to warping, especially when exposed to high temperatures or subjected to excessive pressure. However, the extent of warping depends on various factors such as the thickness of the sheet, the specific alloy used, and the conditions it is exposed to.

- Q: What are the different types of surface treatments available for powder-coated aluminum sheets?

- There are several different types of surface treatments available for powder-coated aluminum sheets. Some of the most common options include anodizing, chemical etching, and mechanical finishing. Anodizing is a process that involves immersing the aluminum sheets in an electrolytic solution and applying an electric current to create a protective oxide layer on the surface. This treatment can enhance the durability and corrosion resistance of the aluminum, as well as provide a decorative finish with a wide range of colors. Chemical etching is another surface treatment method that involves applying a chemical solution to the aluminum sheets to create a textured or patterned surface. This process can be used to create unique designs and improve the aesthetics of the material. Mechanical finishing techniques, such as brushing or polishing, can also be used to enhance the appearance and texture of powder-coated aluminum sheets. Brushing creates a brushed or linear pattern on the surface, while polishing creates a smooth and glossy finish. Additionally, there are specialized surface treatments available for specific applications, such as chromate conversion coating for improved adhesion of adhesives or paints, or clear coatings for added protection against UV radiation. Overall, the choice of surface treatment for powder-coated aluminum sheets depends on the desired aesthetic, functionality, and durability requirements of the application.

- Q: How do aluminum sheets perform in terms of creep resistance?

- Aluminum sheets are known for their excellent creep resistance. Creep is the tendency of a material to slowly deform under a constant load over time. Compared to other metals, such as steel, aluminum has a relatively low creep rate, meaning it deforms at a slower rate under the same load and temperature conditions. This makes aluminum sheets suitable for applications requiring dimensional stability and resistance to long-term deformation. Additionally, aluminum's low creep resistance allows it to withstand high temperatures without significant deformation, making it suitable for use in various industries, including aerospace, automotive, and construction. However, it is important to note that the creep resistance of aluminum sheets can vary depending on the alloy used, heat treatment, and other factors, so it is essential to choose the appropriate aluminum alloy and design for specific applications to optimize creep resistance.

- Q: I think I remember that this is true of aluminum foil. When it's charged, it'll push away from itself, I know. Why do magnets have seemingly no effect?

- Aluminum is a non-ferrous metal. Ferrous metals contain Iron which is magnetic. When aluminum has a charge applied to it, it acts like any conductor would, the charge has magnetic properties. the aluminum is still not magnetic, but it acts like a magnet due to the charge.

- Q: What is the shear strength of 101 aluminum sheets?

- The shear strength of 101 aluminum sheets depends on various factors such as thickness, temper, and manufacturing process. Without specific information, it is challenging to provide an accurate answer.

Send your message to us

Aluminum Sheet 2024 for Aircraft rids Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords