Lightweight Aluminum Sheets for Construction Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

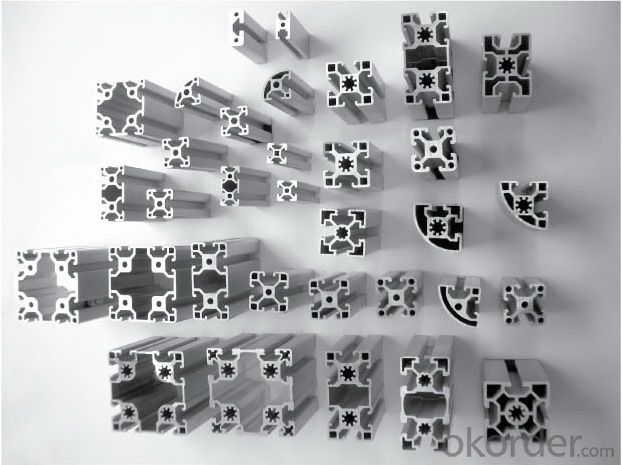

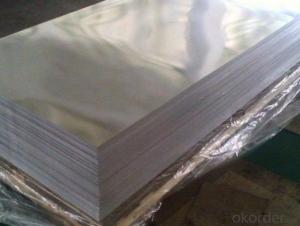

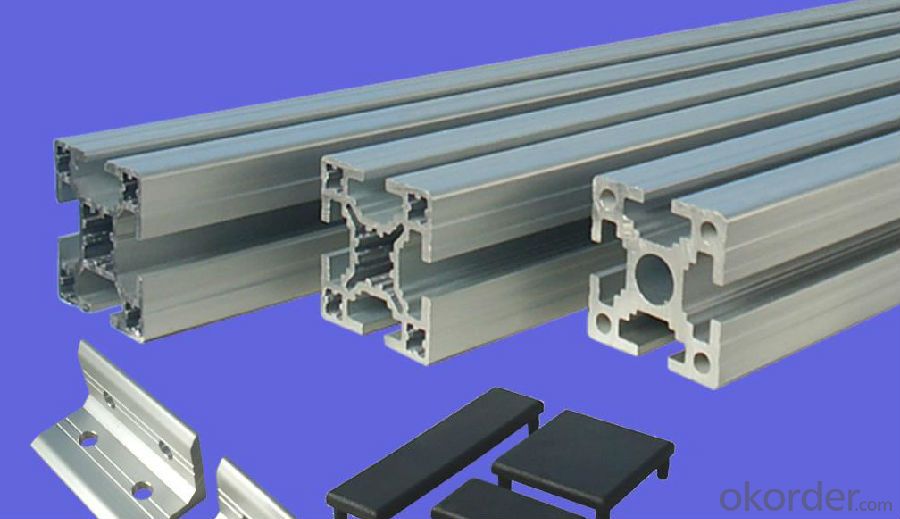

Structure of Aluminium Profile for Construction Application Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Profile for Construction Application:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of Aluminium Profile for Construction Application:

Aluminium Profile for Construction ApplicationSpecification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: How do you prevent distortion of aluminum sheets during welding?

- To prevent distortion during the welding of aluminum sheets, there are several important steps that can be taken: 1. It is crucial to properly prepare the joint by cleaning and beveling the edges of the aluminum sheets. This will ensure a better fit-up and reduce the likelihood of distortion. 2. The use of appropriate fixtures and clamps to hold the aluminum sheets in place during welding can help distribute the heat evenly and prevent movement or buckling. This will minimize the risk of distortion caused by thermal expansion. 3. Tack welding can be done at regular intervals along the joint before performing a full weld. This temporarily secures the sheets and allows for controlled cooling, reducing distortion. 4. Following a proper welding sequence is also beneficial. Starting from the center and gradually moving towards the edges, alternating between sides, helps balance the heat input and allows for cooling between welds, minimizing distortion. 5. Preheating the material before welding can help reduce the temperature gradient and minimize distortion for thicker aluminum sheets. Post-weld heat treatment can also be applied to relieve residual stresses and promote dimensional stability. 6. Employing appropriate welding techniques, such as lowering the heat input and using a slower travel speed, can help minimize distortion. Using a smaller weld bead size and avoiding excessive weaving also control the heat input and reduce distortion. 7. It is crucial to ensure that the welding parameters, such as voltage, current, and wire feed speed, are correctly set and maintained. Using the appropriate parameters for the specific aluminum alloy being welded will result in a more controlled heat input, reducing distortion. By implementing these preventive measures, the risk of distortion during aluminum sheet welding can be significantly reduced, leading to improved weld quality and dimensional stability.

- Q: I need to find 3 elements for my science hw tonight. I was wondering if aluminum foil is a pure element. And also I was wondering if anyone had any ideas of what is a pure element (not a compound or an alloy). Thanks!!!!

- Aluminum metal (symbol Al, atomic # 13) is an element and therefore a pure substance. That said, if something is made out of aluminum (like aluminum foil) it is rarely pure aluminum and is typically an alloy composed of mostly aluminum with other metals. Alloys are used to improve the properties of the pure substance in various ways depending on the desired use.

- Q: Can aluminum sheets be used in marine environments?

- Yes, aluminum sheets can be used in marine environments. Aluminum is a commonly used material in marine applications due to its excellent corrosion resistance properties and lightweight nature. It can withstand the harsh conditions of saltwater, making it suitable for boat building, marine structures, and other marine-related uses.

- Q: Can aluminum sheets be recycled?

- Indeed, it is possible to recycle aluminum sheets. Aluminum stands as one of the extensively recycled substances globally due to its ability to be recycled incessantly without compromising its quality. The recycling of aluminum sheets entails melting them back to their initial form and subsequently molding them into fresh sheets or alternative aluminum commodities. This procedure demands markedly less energy when contrasted with the production of aluminum from primary materials, thus rendering the recycling of aluminum sheets an environmentally viable choice.

- Q: How do aluminum plates drill?

- Can also be a self tapping screw drill, which can drill.

- Q: Are the aluminum sheets suitable for manufacturing aircraft wings?

- Yes, aluminum sheets are suitable for manufacturing aircraft wings. Aluminum is a lightweight and strong material that offers excellent structural integrity, making it a popular choice in the aerospace industry. It also possesses good corrosion resistance and can be easily formed into complex shapes, further contributing to its suitability for aircraft wing manufacturing.

- Q: Can aluminum sheets be used for missile components?

- Yes, aluminum sheets can be used for missile components. Aluminum is a versatile and lightweight material that possesses excellent strength-to-weight ratio properties. These characteristics make it a suitable choice for various aerospace applications, including missile components. Aluminum sheets offer advantages such as corrosion resistance, high thermal conductivity, and ease of fabrication. Additionally, aluminum can withstand extreme temperatures, making it suitable for use in missile components that may experience high heat during flight. However, it is important to consider the specific requirements of the missile system and consult with experts in the field to ensure that aluminum sheets are suitable for the intended application.

- Q: Can aluminum sheets be anodized for improved corrosion resistance?

- Yes, aluminum sheets can be anodized to enhance their corrosion resistance. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the aluminum, making it more resistant to corrosion and increasing its durability.

- Q: Are aluminum sheets suitable for architectural roofing?

- Indeed, architectural roofing can indeed be accomplished with aluminum sheets. Aluminum, being a lightweight substance, is resistant to corrosion, which renders it an optimal selection for roofing purposes. Moreover, it is highly durable and capable of withstanding severe weather conditions, such as extreme temperatures, UV radiation, and strong winds. To add to its appeal, aluminum sheets are accessible in various colors and finishes, granting flexibility in terms of design and aesthetics. Furthermore, aluminum proves to be an environmentally friendly and sustainable material as it can be recycled perpetually without compromising its properties. In summary, aluminum sheets exhibit outstanding performance and versatility, thus making them a favored option for architectural roofing.

- Q: Is aluminum sheet recyclable?

- Yes, aluminum sheet is highly recyclable.

Send your message to us

Lightweight Aluminum Sheets for Construction Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords