Gold Aluminum Foil Sheets for Decorative Aluminum Roof Panels Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

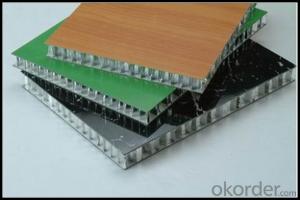

1.Structure of Aluminum Roof Panels for Decoration Supply

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Aluminum Roof Panels for Decoration Supply

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

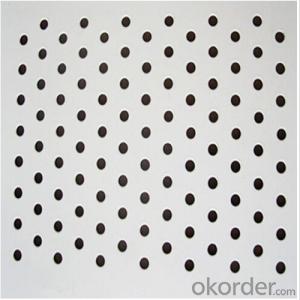

3. Aluminum Roof Panels for Decoration Supply Images

4.Specification of Aluminum Roof Panels for Decoration Supply

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Can aluminum sheets be used in electrical applications?

- Yes, aluminum sheets can be used in electrical applications. Aluminum is a good conductor of electricity and is commonly used in electrical wiring, power transmission lines, and electrical enclosures.

- Q: how to connect copper pipe and aluminum sheet?

- welding!

- Q: Can the aluminum sheets be used for manufacturing medical equipment?

- Medical equipment can be manufactured using aluminum sheets, as they possess several properties that make them appropriate for this purpose. Aluminum is widely utilized in various industries, including healthcare, due to its versatility. To begin with, aluminum is both lightweight and durable, which is advantageous for the production of portable medical devices. This characteristic facilitates the handling and transportation of equipment, particularly for healthcare professionals who may need to move them frequently. Additionally, aluminum exhibits exceptional resistance to corrosion, rendering it suitable for medical applications where cleanliness and hygiene are paramount. It can endure disinfection processes without suffering any deterioration, thus ensuring the longevity of the equipment. Moreover, aluminum can be easily sterilized, which is crucial for medical equipment. It can withstand high-temperature sterilization methods, such as autoclaving, without experiencing any detrimental effects on its structural integrity. Furthermore, aluminum possesses excellent heat and electricity conduction properties. These attributes are beneficial for medical equipment that requires efficient heat dissipation or electrical conductivity, such as surgical instruments or diagnostic tools. Furthermore, aluminum is non-toxic, making it safe for medical use. It does not release harmful substances, guaranteeing the absence of health risks to both patients and healthcare professionals. In conclusion, aluminum sheets are indeed suitable for the manufacturing of medical equipment due to their lightweight nature, durability, corrosion resistance, sterilization capabilities, thermal and electrical conductivity, as well as their non-toxicity. These properties make aluminum an appropriate choice for various medical applications, thereby contributing to the advancement of healthcare technology.

- Q: Are 101 aluminum sheets suitable for food packaging?

- Indeed, 101 aluminum sheets prove to be apt for food packaging purposes. The food packaging industry widely embraces aluminum owing to its remarkable attributes. Notably, it boasts a lightweight nature, durability, and resilience against corrosion, rendering it an ideal substance for maintaining the freshness and caliber of food products. Moreover, aluminum serves as a commendable shield against light, moisture, and oxygen, thereby prolonging the shelf life of packaged edibles. Thus, it is evident that opting for 101 aluminum sheets is a fitting decision for food packaging endeavors.

- Q: does anyone know how much aluminium is recycled per year worldwide compared to how much is produced? Even if you know the stats just for Australia or America it would helpthanksxx

- 45% The fact that they can be recycled to produce more cans means there is no excuse for many people to unaware of aluminum recycling. People should also be aware of the benefits that can occur from it. This has created a strong awareness of the recycling nature of cans and this has been a key factor in the growth of this area. In many canteens, dinner halls and corridors across schools and places of work there is a recycling bin. Wherever people can be found drinking from a soft drink can, a specific aluminum recycling bin can be found for cans to be placed in. Compared to the recycling of many other products, it is easier to find a recycle bin. The provisions for recycling soft drink cans have been more progressively tackled and many people are aware of the need to recycle soft drink cans. This has created awareness and knowledge about recycling and this has moved from school to the outside world. One of the major tactics of marketing departments is to target children and get them to pass the message through to all the family. This is usually done in a bad manner but it can also be done promote recycling. You may see people who go around picking up cans that are thrown away without thought and send them to a recycling center. There are some recycling centers that will make payment for numbers of soft drinks that are recycled. This is a way for people to make some money. It would take a phenomenal amount of aluminum recycling to make a fortune. However, it can help the environment and make a small amount of money back so many people can find the motivation to recycle. There are many places that could be a great source of finding soft drink cans that are thrown away: - School playgrounds - The beach - The car park - Parking lots - Busy streets The amount of products that are available to be recycled continues to grow but it is unlikely that they will grow to be more popular than aluminium recycling.

- Q: What is the maximum width available for aluminum sheets?

- The maximum width of aluminum sheets can differ depending on the manufacturer and specific specifications. Typically, aluminum sheets can be found in widths up to 72 inches or 1.83 meters. It should be emphasized that certain manufacturers may provide wider choices for specialized purposes. Furthermore, personalized dimensions can be acquired by placing specific orders, providing more freedom in selecting the desired width.

- Q: What are the maximum dimensions of aluminum sheets?

- The maximum dimensions of aluminum sheets can vary depending on the specific manufacturing capabilities and requirements. However, commonly available aluminum sheets often have a maximum width of around 72 inches (6 feet) and a maximum length of approximately 240 inches (20 feet).

- Q: Are aluminum sheets suitable for lighting fixtures?

- Yes, aluminum sheets are suitable for lighting fixtures. Aluminum is a versatile and durable material that is commonly used in the manufacturing of lighting fixtures. It offers several advantages that make it a popular choice for this purpose. Firstly, aluminum is lightweight, which makes it easier to handle and install lighting fixtures. It is also highly corrosion-resistant, ensuring that the fixtures can withstand various environmental conditions without deteriorating or rusting over time. Additionally, aluminum has excellent thermal conductivity, allowing it to efficiently dissipate heat generated by the lighting fixtures, which helps in preventing overheating and prolonging their lifespan. Moreover, aluminum can be easily shaped and formed into various designs, making it ideal for creating aesthetically pleasing lighting fixtures. It can be extruded, rolled, or stamped to achieve different shapes and sizes, allowing for a wide range of creative possibilities. Furthermore, aluminum is a cost-effective material compared to other metals commonly used in lighting fixtures, such as brass or copper. It is readily available and has a lower price point, making it a more affordable option for both manufacturers and consumers. In summary, aluminum sheets are indeed suitable for lighting fixtures due to their lightweight nature, corrosion resistance, excellent thermal conductivity, versatility in design, and cost-effectiveness.

- Q: Are aluminum sheets suitable for automotive heat shields?

- Yes, aluminum sheets are suitable for automotive heat shields. They have excellent thermal conductivity and high melting point, making them effective in dissipating heat and protecting sensitive components from excessive temperature. Additionally, aluminum is lightweight and corrosion-resistant, which are desirable qualities for automotive applications.

- Q: Are aluminum sheets suitable for automotive suspension components?

- Automotive suspension components can indeed be made from aluminum sheets, which offer numerous advantages. Firstly, aluminum sheets are much lighter than traditional steel components. This reduction in weight can lead to improved fuel efficiency and overall vehicle performance. By reducing the weight of suspension components, the vehicle's handling, acceleration, and braking can be enhanced, resulting in a smoother and more responsive ride. Secondly, aluminum possesses an excellent strength-to-weight ratio. This means that it can provide the necessary structural integrity and support for suspension components while still being lightweight. It has high tensile strength and stiffness, enabling it to withstand the stresses and forces exerted on suspension components during normal driving conditions. Furthermore, aluminum is highly resistant to corrosion, which is especially beneficial for automotive suspension components that are exposed to various environmental conditions. This corrosion resistance ensures the longevity and durability of the suspension system, reducing the need for frequent repairs or replacements. Moreover, aluminum is easily machinable, allowing for the creation of complex and intricate designs that can optimize suspension performance. Its flexibility in shaping and forming enables manufacturers to create suspension components with specific geometries and characteristics to meet the desired performance requirements. In conclusion, aluminum sheets are an excellent choice for automotive suspension components due to their lightweight nature, high strength-to-weight ratio, corrosion resistance, and machinability. These properties make aluminum a preferred material for suspension components, resulting in improved vehicle performance, fuel efficiency, and overall durability.

Send your message to us

Gold Aluminum Foil Sheets for Decorative Aluminum Roof Panels Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords