Aluminum Profiles Dubai Aluminum Sections

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

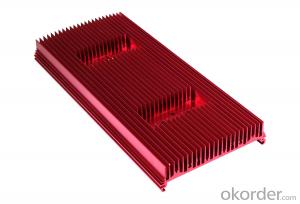

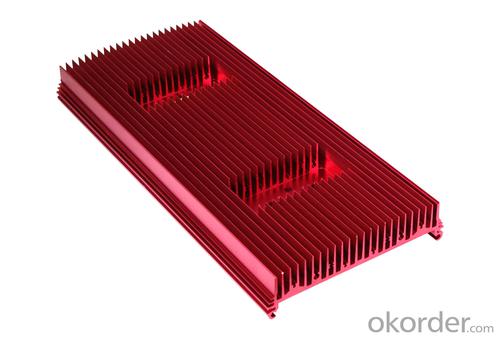

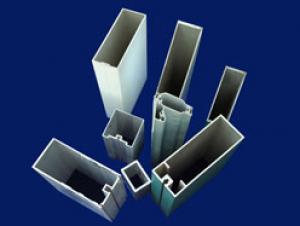

Industrial aluminium profile

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

- Q: What are the different finishing options available for aluminum profiles?

- There are various finishing options available for aluminum profiles to enhance their appearance and provide additional protection. These options can be broadly categorized into surface treatments and coatings. Surface treatments include anodizing, powder coating, and polishing. Anodizing is a popular technique that involves creating a durable and corrosion-resistant layer on the aluminum surface through an electrochemical process. It provides a wide range of colors and finishes while maintaining the metallic look. Powder coating involves applying a dry powder to the aluminum surface and then curing it using heat, resulting in a smooth and durable finish. Polishing is another option that involves mechanically smoothing the surface of the aluminum, giving it a reflective and glossy appearance. Coatings, on the other hand, involve the application of a protective layer on the aluminum. These coatings can be organic or inorganic. Organic coatings, such as paint or lacquer, provide a decorative finish and protect the surface from scratches and oxidation. Inorganic coatings, such as ceramic or enamel, are more durable and resistant to abrasion, heat, and chemicals. Additionally, aluminum profiles can also undergo mechanical finishing processes like brushing or sandblasting. Brushing gives the aluminum a textured finish by using abrasive brushes to create a pattern on the surface. Sandblasting involves forcibly propelling fine particles at high speed to roughen the surface, giving it a matte appearance. The choice of finishing option depends on the intended application, aesthetic preference, and the desired level of protection. Each option has its advantages and disadvantages, so it is essential to consider factors like durability, maintenance, and cost before selecting the appropriate finishing option for aluminum profiles.

- Q: This question asks for an overview of the typical materials used in the production of aluminum profiles.

- <p>Aluminum profiles are commonly made from various aluminum alloys, each with specific properties suited for different applications. The most common materials include 6063 aluminum alloy, known for its good mechanical properties and corrosion resistance, making it ideal for construction and industrial applications. 6061 aluminum alloy is also widely used due to its high strength-to-weight ratio and is often found in aerospace and automotive industries. Other alloys such as 6082 and 7075 are used for their superior strength and are common in heavy-duty applications. Each alloy is chosen based on the required strength, weight, and resistance to environmental factors for the intended use of the aluminum profile.</p>

- Q: Are aluminum profiles suitable for cleanroom applications?

- Yes, aluminum profiles are suitable for cleanroom applications. Aluminum is a lightweight and durable material that is resistant to corrosion, making it ideal for use in cleanroom environments where cleanliness and hygiene are paramount. Aluminum profiles can be easily cleaned and sterilized, and their smooth surface prevents the accumulation of dirt, dust, or particles that can contaminate the cleanroom atmosphere. Additionally, aluminum profiles can be customized and easily integrated with other cleanroom components, such as panels and doors, to create a seamless and hygienic environment. Overall, aluminum profiles offer the required strength, cleanliness, and versatility needed for cleanroom applications.

- Q: This question asks about the various finishing options that can be applied to aluminum profiles.

- <p>Aluminum profiles can be finished in several ways to enhance their appearance and durability. Common types of finishes include: 1. Anodizing, which provides a protective oxide layer and can be colored. 2. Powder coating, a durable and customizable finish that offers a wide range of colors and textures. 3. Electrophoretic coating, which results in a smooth, even finish and is often used for automotive parts. 4. Polishing, which can produce a mirror-like finish. 5. Brushing, which creates a鍝戝厜 texture with a satin-like appearance. 6. Painting, which can be done with solvent-based or water-based paints for a variety of color options. 7. Wood grain transfer, which gives aluminum profiles the appearance of wood. Each finish has its own advantages and is chosen based on the specific application and aesthetic requirements.</p>

- Q: Can aluminum profiles be used for exhibition stands or booths?

- Exhibition stands or booths can indeed utilize aluminum profiles. The lightweight and robust characteristics of aluminum make it a favored option for constructing such structures. Its ability to provide structural stability, along with the convenience of transportation and assembly, further adds to its appeal. Aluminum profiles are easily customizable, allowing for their seamless integration into diverse designs and configurations, thereby catering to various exhibition needs. Moreover, aluminum's recyclability aligns with the sustainable practices frequently sought after in the exhibition and event industries. In summary, aluminum profiles present a cost-effective and pragmatic choice for the creation of exhibition stands or booths.

- Q: What is the difference between the two, or how to distinguish it from the outdoor curtain wall?

- Aluminum material refers to the blank material, which is used directly without artificial aging

- Q: Are aluminum profiles suitable for use in aerospace structural components?

- Yes, aluminum profiles are suitable for use in aerospace structural components. Aluminum is a lightweight and corrosion-resistant material that offers a high strength-to-weight ratio, making it ideal for applications in the aerospace industry. It is widely used in the construction of aircraft frames, wings, and other structural components due to its durability and ability to withstand high stress and forces during flight.

- Q: This question asks about the various materials used for insulation purposes when working with aluminum profiles.

- <p>Different types of insulation materials used with aluminum profiles include thermal insulation materials such as polyurethane foam, mineral wool, and polystyrene. These materials help in reducing heat transfer and maintaining temperature control. Additionally, electrical insulation materials like PVC, polyethylene, and silicone rubber are used to prevent electrical conductivity and protect against electrical hazards. Acoustic insulation materials like fiberglass and soundproofing foam are also used to reduce noise transmission through aluminum structures. Each type of insulation serves a specific purpose and is chosen based on the application's requirements.</p>

- Q: Are aluminum profiles suitable for use in industrial settings like shelving and storage systems?

- <p>Yes, aluminum profiles are indeed suitable for industrial applications such as shelving and storage systems. They offer several advantages including high strength-to-weight ratio, corrosion resistance, and ease of assembly. Aluminum profiles are lightweight, which makes them ideal for constructing sturdy yet lightweight shelving and storage solutions. Their resistance to corrosion means they can withstand harsh industrial environments without rusting. Additionally, the modular nature of aluminum profiles allows for customizable designs that can be easily adjusted or reconfigured to meet changing storage needs.</p>

- Q: Can aluminum profiles be used for stage and truss structures?

- Yes, aluminum profiles can be used for stage and truss structures. Aluminum is a lightweight, durable, and versatile material that is commonly used in construction and engineering applications, including stage and truss structures. It offers excellent strength-to-weight ratio, corrosion resistance, and ease of fabrication, making it an ideal choice for such purposes.

Send your message to us

Aluminum Profiles Dubai Aluminum Sections

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords