Aluminum Profiles Dubai Aluminum Sections

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

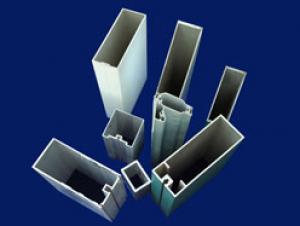

Industrial aluminium profile

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

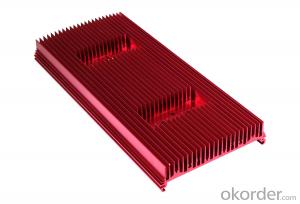

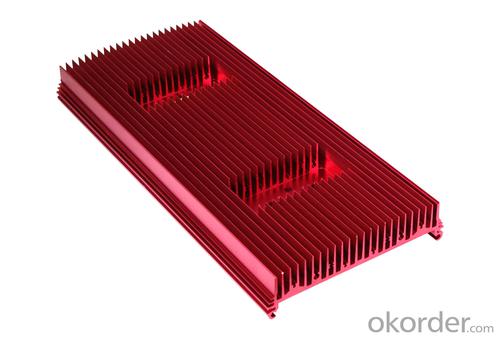

- Q: Who would like to know, aluminum radiator mainly used in which instruments or equipment, trouble to say more detailed points, thank you

- Application of aluminum radiator is quite extensive, you do not know where to, because he has the quality of light, and the price is reasonable, the general electronic instruments and equipment will be used, such as TV, audio amplifier, car circuit board, CPU computer graphics.

- Q: What are the different machining techniques used on aluminum profiles?

- There are several machining techniques commonly used on aluminum profiles to shape and modify them according to specific requirements. These techniques include: 1. Milling: Milling is a versatile technique that involves removing material from the aluminum profile using rotary cutters. It can be used to create various features such as slots, pockets, and contours on the profile's surface. 2. Drilling: Drilling is a machining technique that creates holes in the aluminum profile. It is commonly used for creating holes for fasteners or for other components to be attached to the profile. 3. Turning: Turning is a process where the aluminum profile is rotated while a cutting tool is used to remove material and shape the profile. This technique is often used to create cylindrical shapes or to remove excess material from the profile. 4. Grinding: Grinding involves using an abrasive wheel to remove material from the aluminum profile's surface. It is commonly used to achieve a smooth and polished finish or to remove any imperfections on the profile. 5. Bending: Bending is a technique used to reshape the aluminum profile by applying force to it. This technique is often used to create curved or angled profiles. 6. Tapping: Tapping is a process that creates internal threads in the aluminum profile. It is commonly used when fasteners need to be screwed into the profile. 7. Sawing: Sawing is a technique where a saw blade is used to cut through the aluminum profile. It is often used when the profile needs to be cut into specific lengths or shapes. 8. Welding: Welding is a joining technique where two or more aluminum profiles are fused together using heat and pressure. It is commonly used to create complex structures or to join different profiles together. These are just a few of the machining techniques used on aluminum profiles. The choice of technique depends on the specific requirements of the project and the desired outcome.

- Q: This question asks for a list of various types of coatings applied to aluminum profiles to prevent corrosion.

- <p>Aluminum profiles are protected from corrosion through several types of coatings. These include: Anodizing, which forms a protective oxide layer; Powder Coating, a durable and weather-resistant finish; Electrophoretic Deposition (E-coat), offering a smooth, corrosion-resistant surface; Fluoropolymer coatings, known for their exceptional chemical resistance and UV stability; and Thermal Spray Coatings, which provide a hard, wear-resistant surface. Each method serves to enhance the aluminum's resistance to environmental factors and extend its lifespan.</p>

- Q: Explain the various methods used to install aluminum profiles in construction projects.

- <p>There are several methods to install aluminum profiles in construction: 1. Bolting: Aluminum profiles can be secured with bolts and nuts, providing a strong and adjustable connection. 2. Welding: For permanent and rigid connections, aluminum profiles can be welded together. 3. Adhesive bonding: Using specialized adhesives, aluminum profiles can be bonded together for a secure fit. 4. Clipping: Some profiles come with clip-on connectors that allow for quick and easy assembly. 5. Screwing: Self-tapping screws can be used to join aluminum profiles, providing a strong hold without the need for pre-drilled holes. 6. Mortise and tenon: A traditional woodworking joint that can be adapted for aluminum profiles, creating a tight and secure fit. Each method has its advantages and is chosen based on the specific requirements of the construction project.</p>

- Q: Are aluminum profiles suitable for exhibition booths?

- Yes, aluminum profiles are suitable for exhibition booths. Aluminum is a versatile and lightweight material that offers various benefits for exhibition booth construction. Firstly, aluminum profiles are easy to work with and can be easily cut, drilled, and assembled to create custom booth designs. This flexibility allows for creativity and customization to meet specific booth requirements. Additionally, aluminum profiles are highly durable and long-lasting. They are resistant to corrosion, rust, and other environmental factors, which ensures that the exhibition booth can withstand the rigors of multiple events and maintain its appearance over time. This durability also makes aluminum profiles a cost-effective choice, as they require minimal maintenance and can be reused for future exhibitions. Furthermore, aluminum profiles offer a sleek and professional aesthetic that can enhance the overall presentation of the exhibition booth. The material can be finished with various coatings, such as paint or anodizing, to achieve the desired look and branding. Moreover, aluminum profiles can be easily integrated with other materials, such as glass, acrylic, or fabric, to create visually appealing displays within the booth. Lastly, aluminum profiles provide structural stability while remaining lightweight. This is crucial for exhibitors who need to transport and assemble their booths frequently. The lightweight nature of aluminum profiles makes them easy to handle, reducing logistical challenges and costs associated with booth setup and dismantling. Overall, aluminum profiles offer numerous advantages that make them suitable for exhibition booths. Their versatility, durability, aesthetic appeal, and ease of use make them an excellent choice for exhibitors looking to create eye-catching and functional booth designs.

- Q: This question asks for a list of various interior wall cladding systems that incorporate aluminum profiles.

- <p>Aluminum profiles are versatile and commonly used in interior wall cladding systems due to their durability and aesthetic appeal. Some of the different types include: 1. Aluminum Composite Panels (ACP), which combine two aluminum sheets with a non-aluminum core. 2. Aluminum Insulated Panels, offering thermal insulation properties. 3. Aluminum Curtain Wall Systems, providing a weather-resistant exterior wall. 4. Aluminum Lining Systems, used for decorative purposes and easy maintenance. 5. Aluminum Ceiling Systems, which can also serve as wall cladding in some designs. 6. Aluminum Drywall Systems, which are lightweight and easy to install. Each system has its specific applications and advantages, making aluminum profiles a popular choice in modern architecture and interior design.</p>

- Q: Are aluminum profiles compatible with other materials for construction purposes?

- <p>Yes, aluminum profiles can be used in combination with other materials in construction. They are often paired with steel, glass, and various plastics due to their lightweight, durability, and corrosion resistance. Aluminum's ability to be easily joined and its compatibility with different finishes make it a versatile choice for construction projects.</p>

- Q: Can aluminum profiles be used in outdoor applications?

- Yes, aluminum profiles can be used in outdoor applications. Aluminum is a versatile and durable material that is resistant to corrosion and weathering, making it suitable for outdoor use. It is commonly used in the construction industry for outdoor structures such as fences, railings, pergolas, and outdoor furniture. Additionally, aluminum profiles can be treated with various coatings or finishes to enhance their resistance to UV rays, moisture, and other environmental factors. Overall, aluminum profiles offer a reliable and long-lasting solution for outdoor applications.

- Q: Are aluminum profiles suitable for decorative applications?

- <p>Yes, aluminum profiles are commonly used for decorative purposes. They offer a sleek, modern look and are lightweight, durable, and resistant to corrosion. They can be anodized or powder coated in various colors to match different design aesthetics. Aluminum profiles are versatile and can be used in architectural features, furniture, and various other decorative elements.</p>

- Q: Can recycled aluminum be utilized in construction projects as an alternative to new, raw materials?

- <p>Yes, recycled aluminum can be used in building projects as an alternative to new raw materials. It is not only cost-effective but also environmentally friendly, reducing the energy required for production and the amount of waste sent to landfills. Recycled aluminum maintains the same strength and durability as new aluminum, making it suitable for various construction applications. However, it's important to ensure that the recycled aluminum meets the necessary quality standards and specifications for your project to avoid any structural or safety issues.</p>

Send your message to us

Aluminum Profiles Dubai Aluminum Sections

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords