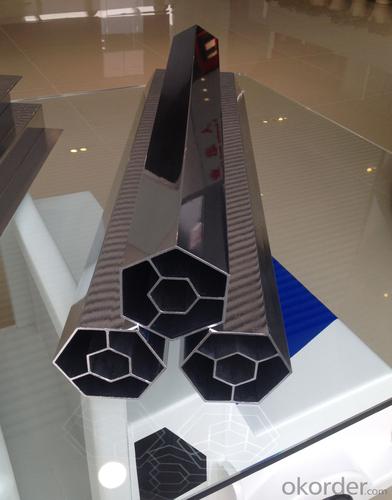

Aluminum Pipes for Vehicle Structure Aluminum Profile

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are the largest aluminum profilemanufacture in

Material | Alloy Aluminum 6063,6061,6005,6082 or customer nominated |

Temper | T3, T4, T5, T6 and other |

Surface | Anodize, electrophoresis, Mill,etc |

Colour | -- |

Length | Not more than 16 meters |

Good Package | Inner plastic film /outside carton/wooden pallets |

Payment Method | T/T, L/C, etc |

Delivery Time | Normally 2-4 weeks, Delivery time can be consulted. |

Press Machine | 500-12500 tons all together 93 press lines. |

Fabrication | 1. Car body; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO/TS 16949,DNV,IRIS,CCS,AFA,etc. |

Dies | 1. Using our dies, no fee; |

2. Using customer drawing, opening dies, usually about 5~50 tons then the dies cost can be refunded. | |

3. Die cost is negotiable base on the order quantity | |

Capability | Annual output 800,000 tons |

- Q: The company has an aluminum product with high precision (less than 0.1mm). Aluminum profiles manufacturers can do so to achieve this accuracy. However, when the oxidation of the problem, the oxidation process, due to various reasons, there will be repeated rework, repeated oxidation phenomenon.. There is an aluminum oxide 3 times, even after the small 0.06mm. More exaggeration is that there is a small number of aluminum parts, the number of oxidation is five or six times, directly leading to size coordination, delivery, affecting the use of products. The other side also said it is difficult to control the number of oxidation, can not avoid repeated oxidation phenomenon.. Is it really oxidation that leads to smaller size? What's the solution?

- Will aluminum tubes become smaller after oxidation? Or after the oxidation section factory again suppressed shaping? Arguably, aluminum oxidation texture should become loose, profile factory should also be a set of professional solutions to deal with the possible problems in the deformation of metal products processing, but also should have their own set of data and tolerance of quality control and evaluation... If he can not control the oxidation number of products lead to invalid they can only say, technology has not yet reached the precision products...

- Q: I have a meter square radiator (copper tubes, aluminum tubes are), I would like to know how to remove the scale inside, looking forward to your master answer 5Do you need any chemical reagents?heyHow do you handle the copper tube and the aluminum tube separately?

- Comrade hydrochloric acid can be, but do not have a long time, or else the aluminum pipe is gone, ha ha!

- Q: Who has good refrigerator, aluminum tube butt joint method, welding technology?. Thank you

- I can weld the copper tube and the aluminum tube, but I'm not sure I can make it clear. Pipe butt welding to argon arc welding, in the middle two aluminum tubes with a brass copper aluminum welding, because just a little bit more simple.

- Q: Can aluminum pipes be used for scaffolding?

- Aluminum pipes are indeed suitable for scaffolding purposes. Due to their lightweight characteristic, high strength-to-weight ratio, and resistance to corrosion, aluminum is widely favored for scaffolding applications. These qualities render aluminum pipes perfect for the construction of scaffolding systems that are simple to handle, transport, and assemble. Moreover, aluminum scaffolding is renowned for its durability and long-lasting nature, making it an economically viable choice in the long term. Nevertheless, it is crucial to ensure that the aluminum pipes employed for scaffolding adhere to the required safety standards and regulations to safeguard the well-being of workers.

- Q: How can the refrigerator be welded with copper aluminum tube?

- Welding powder, copper electrode can be used welding!AskExcuse me, is God welding powder? Can you give me more details? Thank you.Chasing the answerI used borax, and now I'm not sure what it is. Now are selling refrigeration parts, where to buy welding powder and welding rod, welding powder 5 pieces, 2 pieces of welding rod!

- Q: Are aluminum pipes suitable for food packaging systems?

- Yes, aluminum pipes are suitable for food packaging systems. Aluminum is a safe and reliable material for packaging food due to its non-toxic nature, excellent barrier properties against light, oxygen, and moisture, and its ability to maintain the quality and freshness of food products. Additionally, aluminum pipes are lightweight, resistant to corrosion, and can be easily recycled, making them an environmentally friendly choice for food packaging systems.

- Q: What are the different pressure testing methods for aluminum pipes?

- To ensure the integrity and reliability of aluminum pipes, there are multiple methods available for pressure testing. These methods can vary depending on factors like the pipe's application, size, material thickness, and industry standards. It is essential to consult experts or refer to industry codes and regulations to determine the most suitable testing method for a specific situation. One commonly used technique is hydrostatic testing. This method involves filling the aluminum pipe with water or another liquid and pressurizing it to a predetermined level. The pipe is then inspected for leaks or any abnormal behavior under pressure. Hydrostatic testing is a straightforward, cost-effective method that yields accurate results. Alternatively, pneumatic testing can be employed. Instead of using liquid, air or inert gas is used to pressurize the aluminum pipe. The pipe is sealed, and the pressure is gradually increased until the desired test pressure is reached. Any leaks or deformations are then examined. Pneumatic testing is particularly useful when water or other liquids could be harmful to the pipe material. Ultrasonic testing is a non-destructive method that utilizes ultrasonic waves to detect flaws or defects in the aluminum pipe. Transducers are employed to transmit and receive these waves, and changes in their characteristics indicate the presence of defects. This type of testing can be conducted without applying pressure to the pipe. Magnetic particle testing, on the other hand, is specifically designed to identify surface cracks or defects in aluminum pipes. By creating a magnetic field around the pipe and applying finely divided magnetic particles to the surface, any surface defects will attract the particles, making them visible for inspection. Radiographic testing involves using X-rays or gamma rays to examine the internal structure of aluminum pipes. The pipe is exposed to these rays, and the resulting image is analyzed for any defects or abnormalities. While radiographic testing is highly accurate, it requires specialized equipment and trained personnel. In summary, there are several pressure testing methods available for aluminum pipes, including hydrostatic testing, pneumatic testing, ultrasonic testing, magnetic particle testing, and radiographic testing. The selection of the appropriate method depends on various factors, and seeking guidance from experts or referring to industry codes and regulations is crucial for determining the most suitable testing method for a specific situation.

- Q: Are aluminum pipes suitable for stadium lighting structures?

- Yes, aluminum pipes are suitable for stadium lighting structures. Aluminum is a lightweight yet durable material that can withstand harsh weather conditions, making it ideal for outdoor applications like stadium lighting. It is corrosion-resistant, has excellent electrical conductivity, and is easy to install and maintain, making it a popular choice for such structures.

- Q: What are the different diameters available for aluminum pipes?

- The different diameters available for aluminum pipes can vary widely, ranging from small sizes like ¼ inch or 6.35mm to larger diameters such as 12 inches or 304.8mm. The specific diameters available will depend on the manufacturer and the intended application of the aluminum pipes.

- Q: resulting in the pipe can not be used after folding, how to deal with? Fifteen08 years to buy three AUX air-conditioning, moving this year, the pipe was folded, and then installed, AUX said after the sale of the pipe can not be used, to replace all new, because the aluminum pipe can not be welded. We all know that the tube is very expensive, then bought 5 meters or so, I think it will not have to spend money again, I did not expect, because of this reason, even for old pipes, the installation of new tubes, but also spend nearly 1000 yuan. When I bought it, I didn't think they would use the aluminum tube. I thought it was copper. It was entirely cost saving by the factory, which made the consumer pay the bill. I was so angry that I didn't buy anything from AUX any more. Would you like to ask if you have ever touched this situation? What can you do to reuse the old pipes?

- At that time, bought 5 meters or so, I think it will not have to spend money again, I did not expect, for this reason, even for the old pipe, the installation of new tubes, but also spend nearly 1000 yuan. They didn't think they could use aluminum tubes, but they thought they were copper...5 meters, 1000? How do you count it? 3 is the three AUX air conditioning are what count?Copper can buy it yourself, one meter 25--35 3P 1.5P meters, 60---70 to buy their own.Aluminum tube is folded, dead, or no folding, and that is the sense of aluminum tube can pass, if it can pass, you can use the tube folder.Thanks for taking it

Send your message to us

Aluminum Pipes for Vehicle Structure Aluminum Profile

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords