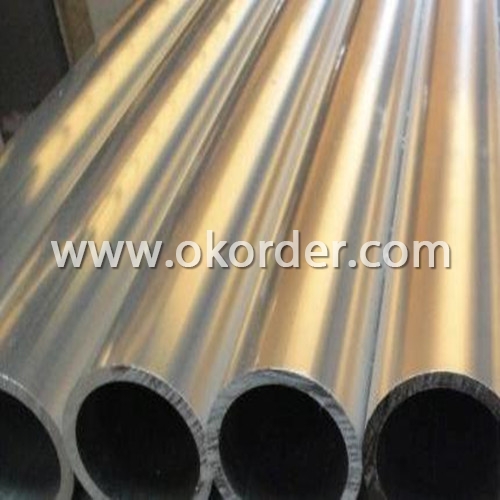

Aluminum Pipes 3xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of Aluminum Pipes 3XXX

Alloy Number | AA 3XXX |

Temper | O, F,H112,T4,T5,T6,T3,T8 |

Thickness | 0.5-50mm |

Length | <=13m |

Diameter | Outer: 9-500mm |

Standard | GB/5237.2-2004, ASTM, ISO, EU standard |

Special specification is available on customers' requirements.

2. Usage/Applications of Aluminum Pipes 3XXX

Aluminum pipes are widely used for building construction, housing decorations, industry & agriculture & architecture usage etc.

3. Packaging & Delivery of Aluminum Pipes 3XXX

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment: the goods will be delivered in 30 days after getting the buyer's payment.

4. Production Flow of Aluminum Pipes 3XXX

Casting--extruding--cutting--coating—further processing--packing

- Q: Are aluminum pipes suitable for outdoor lighting fixtures?

- Outdoor lighting fixtures can indeed be suitably made from aluminum pipes. This material, known for its high durability and resistance to corrosion, is ideal for use in outdoor environments where the fixtures will be subjected to different weather conditions. Due to its lightweight nature, aluminum pipes are easy to handle and install. Furthermore, aluminum exhibits excellent thermal conductivity, ensuring efficient heat dissipation, a crucial factor for outdoor lighting fixtures that may produce heat. In summary, aluminum pipes offer a dependable and enduring solution for outdoor lighting fixtures.

- Q: What's the difference between 6061 tubes and 6063?

- in order to improve the cutting performance, adding lead and bismuth. In Mg2Si, the Mg/Si ratio is 1.73,

- Q: How do aluminum pipes compare to HDPE pipes in terms of flexibility?

- Aluminum pipes and HDPE pipes differ in terms of flexibility. HDPE pipes are known for their high flexibility due to the nature of the material they are made from. High-density polyethylene (HDPE) is a thermoplastic polymer that possesses a high degree of elasticity and flexibility. This allows HDPE pipes to be easily bent, twisted, and maneuvered around obstacles during installation. On the other hand, aluminum pipes are generally less flexible compared to HDPE pipes. Aluminum is a metal that has a higher rigidity and stiffness compared to HDPE. This means that aluminum pipes are less able to bend or flex without sustaining damage or deformation. They are better suited for applications that require more structural integrity and rigidity, such as in industrial or heavy-duty environments. While aluminum pipes may not be as flexible as HDPE pipes, they offer other advantages such as higher strength, corrosion resistance, and the ability to handle higher pressure and temperature conditions. The choice between aluminum and HDPE pipes should be based on the specific requirements of the project, considering factors such as flexibility, strength, durability, and the environment in which they will be used.

- Q: Can aluminum pipes be used for high-pressure applications?

- Yes, aluminum pipes can be used for high-pressure applications. Aluminum is a lightweight, durable, and corrosion-resistant material, making it suitable for various industries and applications, including high-pressure systems. However, the specific pressure rating of an aluminum pipe depends on its size, wall thickness, and alloy composition. It is important to consult industry standards and guidelines, as well as engineering professionals, to ensure that the chosen aluminum pipe is suitable for the intended high-pressure application.

- Q: How to repair the surface defects of aluminum pipe

- Method: to hand percussion pits with oxyacetylene flame annealing, after cooling, use hand hammer into the aluminum oblate tube, estimated knocking position try to knock, knock point and observe from the outside, adjusted and confirmed the knock point after the afterburner struck, until the elimination of pits. If it is difficult to strike in the middle, it is expected to be hardened by metal hammering. It must be reheated and annealed again, and then continue after cooling. The method is generally applicable to the repair of the larger diameter aluminum tube and the hand length of the pit. Not suitable for trimming of flattening defects

- Q: Now a part of the connecting pipe of the air conditioner from the past to pure copper aluminum copper combined pipe, aluminum copper pipe is better seller says. Is it better in the end? Please help me professional fans.

- Air conditioning connecting tube using copper and aluminum composite pipe is certainly not good, but cheaper.The connecting pipe of the copper aluminum composite pipe is an aluminum tube in the middle, and the copper pipe is welded at both ends, and there are several reasons for the bad:1, welding position is easy leaking and physical reaction.2, aluminum tube easy flat, fold.

- Q: What are the different insulation options for aluminum pipes?

- There are several insulation options available for aluminum pipes. One of the most common options is fiberglass insulation. This type of insulation is made of small fibers of glass that are woven together to create a blanket-like material. Fiberglass insulation is effective at reducing heat loss or gain in aluminum pipes and is relatively inexpensive. Another option is foam insulation, which is typically made of closed-cell or open-cell foam. Closed-cell foam insulation is denser and provides better thermal insulation, while open-cell foam is more lightweight and flexible. Foam insulation is easy to install and provides good protection against condensation and heat transfer. Another alternative is elastomeric insulation. Elastomeric insulation is made of synthetic rubber and is commonly used for pipes that carry chilled or hot water. It is flexible, easy to install, and has excellent thermal insulation properties. Elastomeric insulation is also resistant to UV radiation and moisture, making it suitable for outdoor applications. Additionally, reflective insulation can be used for aluminum pipes. Reflective insulation consists of a layer of aluminum foil that is attached to a backing material. This type of insulation reflects radiant heat away from the pipe, reducing heat gain or loss. Reflective insulation is lightweight, easy to install, and can be used in both indoor and outdoor applications. Finally, there are also mineral wool and ceramic fiber insulation options available for aluminum pipes. Mineral wool insulation is made of natural or synthetic fibers and provides good thermal and acoustic insulation. Ceramic fiber insulation is made of high-temperature materials and is suitable for pipes that carry extremely hot substances. Ultimately, the choice of insulation for aluminum pipes depends on factors such as the desired level of thermal protection, the environment in which the pipes are located, and the specific requirements of the application. It is important to consider these factors and consult with professionals to determine the most suitable insulation option for aluminum pipes.

- Q: Brass or aluminium tube for internal and external air conditioner?

- Some manufacturers for the cost on the tubes, each also has been used before, Rui tubes, not how many years

- Q: Can aluminum pipes be anodized for improved corrosion resistance?

- Yes, aluminum pipes can be anodized for improved corrosion resistance. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the aluminum. This oxide layer is highly resistant to corrosion and can greatly enhance the durability and lifespan of the aluminum pipes. Anodizing also provides additional benefits such as increased hardness, improved adhesion for paints and coatings, and enhanced aesthetic appearance. The anodized layer can be dyed in various colors to achieve a desired look. The process involves immersing the aluminum pipes in an electrolyte solution and passing an electric current through it, which causes the formation of the oxide layer. Overall, anodizing is an effective and widely used method to enhance the corrosion resistance of aluminum pipes.

- Q: Can aluminum pipes be used for irrigation pumps?

- Certainly! Irrigation pumps can indeed utilize aluminum pipes. Renowned for their lightweight nature, durability, and resistance to corrosion, aluminum pipes prove to be a fitting option for irrigation systems. Their exceptional flexibility permits effortless installation and maintenance procedures. Moreover, their commendable heat conductivity aids in effectively dissipating heat from the pump. In summary, aluminum pipes furnish a practical and efficient resolution for irrigation pumps, offering both cost-effectiveness and efficacy.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 2004 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Pipes 3xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords