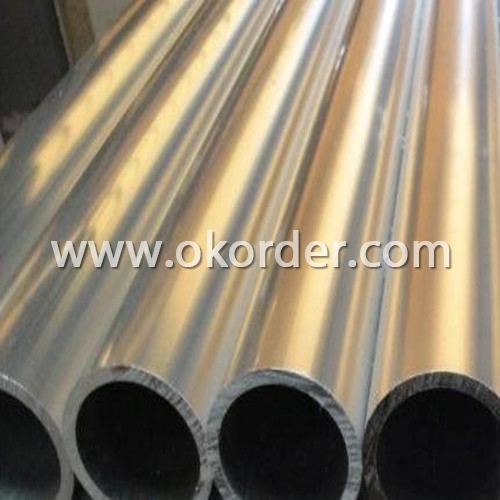

Aluminum Pipes 8xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of Aluminum Pipes 8XXX

Alloy Number | AA 8XXX |

Temper | O, F,H112,T4,T5,T6,T3,T8 |

Thickness | 0.5-50mm |

Length | <=13m |

Diameter | Outer: 9-500mm |

Standard | GB/5237.2-2004, ASTM, ISO, EU standard |

Special specification is available on customers' requirements.

2. Usage/Applications of Aluminum Pipes 8XXX

Aluminum pipes are widely used for building construction, housing decorations, industry & agriculture & architecture usage etc.

3. Packaging & Delivery of Aluminum Pipes 8XXX

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment: the goods will be delivered in 30 days after getting the buyer's payment.

4. Production Flow of Aluminum Pipes 8XXX

Casting--extruding--cutting--coating—further processing--packing

- Q: Need to know the answer urgently. If anyone knows, please answer, thank you.........Supplement: aluminum without primer spraying, spray and spray paint, paint is 22 dilute acid. After spraying up, adhesion is good, not easy to fall, what formula, or in paint which need to add what?

- Only the use of acrylic polyurethane finish, acrylic polyurethane has good weatherability and chemical resistance, but because the paint itself has tiny pores in spraying primer and paint case, after long-term exposure to the sun and rain and other environment, moisture will penetrate the film, and the aluminum contact formation of aluminide, resulting in paint peeling off.The above suggestions for your reference, thank you!

- Q: Why is the copper tube of AUX air conditioning aluminum tube?

- The air conditioning aluminum tube is made of pure aluminium or aluminum alloy and is extruded into a hollow metal tube with longitudinal length. The air conditioning aluminum tube has "anneal"

- Q: What is the cost of aluminum pipes compared to other materials?

- The cost of aluminum pipes can vary depending on various factors such as the size, thickness, and grade of the pipe, as well as the current market conditions. However, generally speaking, aluminum pipes tend to be more affordable compared to other materials such as stainless steel or copper. Aluminum is a lightweight material that is easily accessible and abundant, which helps to keep its production costs relatively lower. Additionally, aluminum pipes do not require as much energy or resources to manufacture compared to other metals, contributing to their lower cost. On the other hand, materials like stainless steel or copper are generally more expensive due to their higher production costs and limited availability. Stainless steel pipes, for example, require additional alloying elements and complex manufacturing processes, which increase their price. Copper pipes, known for their excellent heat conductivity, are also more expensive due to the higher cost of copper as a raw material. It is important to note that the specific cost comparison between aluminum pipes and other materials may vary depending on the market conditions and specific project requirements. Therefore, it is advisable to consult with suppliers or conduct thorough research to get accurate pricing information for the desired materials.

- Q: What is the difference between aluminium pipe and aluminium alloy pipe?

- According to the precision points: ordinary aluminum tube and precision aluminum tube, in which the precision aluminum tube generally needs to be processed after extrusion, such as cold drawn, fine pumping, rolling...

- Q: Are aluminum pipes suitable for stadium lighting structures?

- Indeed, stadium lighting structures can be suitably constructed using aluminum pipes. Due to its lightweight and durable properties, aluminum is an ideal material choice for such structures that necessitate robustness and long-lasting quality. Moreover, aluminum exhibits exceptional resistance to corrosion, a crucial feature for outdoor installations exposed to harsh weather conditions. The lightweight nature of aluminum pipes also facilitates easier handling and installation, thereby reducing construction time and expenses. Additionally, as aluminum is highly conductive, it enables efficient electricity transmission to power the stadium lighting fixtures. In conclusion, aluminum pipes offer a dependable and economically viable solution for stadium lighting structures.

- Q: Are aluminum pipes suitable for outdoor applications?

- Yes, aluminum pipes are suitable for outdoor applications. Aluminum is highly resistant to corrosion, making it a durable option for outdoor use. It also has a high strength-to-weight ratio, making it easy to handle and transport for various outdoor projects. Additionally, aluminum pipes can withstand extreme weather conditions and temperature changes, further enhancing their suitability for outdoor applications.

- Q: Freezer aluminium tube can be used for several years

- Now the refrigerator tube is using aluminum tube or Bondi tube (Bondi tube, that is galvanized steel pipe, in fact, the iron pipe, iron pipe above the paint once lost, it is easy to rust..)

- Q: What are the different sizes of aluminum pipes available?

- There are various sizes of aluminum pipes available, ranging from small diameters like ¼ inch to larger ones like 12 inches or more. The specific sizes will depend on the manufacturer and the intended application of the pipe.

- Q: Which is better, titanium alloy or high pressure aluminium tube?

- we must consider the actual use, can use aluminum alloy place, aluminum alloy than titanium alloy is good, otherwise, titanium alloy is best.

- Q: I have used ab repair several times, each time with only three months and leakage of fluorine, hope you master generous with your criticism,

- The best is aluminum, brass or change.Can also use high temperature electric iron, plus solder wire can also be welded to live

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 2006 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Nanhai Port |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Pipes 8xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords