Extruded Aluminum Tubing Profiles - Aluminium D-Profile According to European Standards

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium D-profile According to European Standards Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium D-profile According to European Standards:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

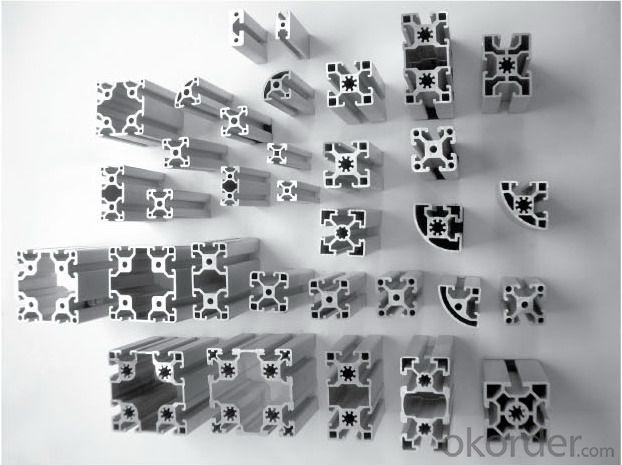

Images of the Aluminium D-profile According to European Standards:

Aluminium D-profile According to European Standards Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium D-profile According to European Standards:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Are aluminum profiles suitable for modular construction?

- Yes, aluminum profiles are highly suitable for modular construction. They are lightweight, yet strong and durable, making them ideal for creating modular structures. Aluminum profiles are easy to fabricate and can be easily assembled or disassembled, allowing for flexibility in design and construction. Additionally, aluminum is resistant to corrosion, which ensures the longevity of the modular construction.

- Q: Is the aluminum profile insulated and broken hot?

- Yes, the name is not the same, the professional name is "broken hot aluminum alloy", most people used to call "broken bridge aluminum"

- Q: Everybody good: please look at this section of the aluminum can not buy ready-made standard parts. If the mold needs to be opened, is it the extrusion process? About how much is the die charge?. Thank you.

- You mold two boxes connected at a relatively small, may die requirements will be much higher, I do not know whether the price will be more expensive.

- Q: What are the different tolerance levels for aluminum profiles?

- The specific requirements and applications can cause the tolerance levels for aluminum profiles to differ. Various industries, including automotive, aerospace, and construction, typically demand aluminum profiles with tight tolerance levels. Aluminum profiles commonly have dimensional tolerances, straightness tolerances, and surface finish tolerances. The dimensional tolerances ensure that the profile meets the required measurements and fits properly in its intended application. Typically, these tolerances are specified in millimeters or inches. Straightness tolerances guarantee that the aluminum profile does not deviate from a perfectly straight line. This is vital for maintaining structural integrity and accurate assembly. Surface finish tolerances determine the acceptable level of imperfections on the profile's surface, such as scratches, indentations, or roughness. These tolerances are often specified in terms of roughness average (Ra) or surface quality codes, like anodized or powder-coated finishes. It is crucial to consider that the tolerance levels for aluminum profiles can vary depending on factors such as the manufacturing process, intended application, and industry standards. Therefore, it is essential to consult relevant specifications, industry standards, or the supplier's guidelines to determine the precise tolerance levels for a specific aluminum profile.

- Q: What are the aluminum profile manufacturers in Jiangsu?

- For the choice of aluminum profiles, here are a few suggestions for you to refer to:First: very cheap, do not chooseAs follows: the cost of industrial aluminum material = the spot price of aluminum ingot, the processing cost of extrusion aluminum material, the freight of packing material. These are transparent, the cost of aluminum profiles are similar, significantly lower than the market price, the first possibility: the weight per meter less; second: aluminum is the use of recycled materials; third: material loss amplification (not according to the actual sales amount of meters).Second: only understand the sale material supplier does not chooseExplain as follows: preparing goods, recruit a few operator, big online promotion can be opened. Those who are often hurt are our buyers. Miss wiring mostly do not know how to use, only know the unit price. How to use to meet customer needs; how to make the most cost-effective; in different venues that kind of connection is the best; these are they can not answer accurately. Only know the cheapest and recommended profile connection the cheapest; this connection is the lowest cost, but the cost of artificial, a connection is the weakest, aluminum convenience wouldn't be reflected, and will bring much trouble for the future reconstruction. But the wiring girl will push it one way.Third: in production of aluminium supplierExplain as follows: in the production of aluminum suppliers, are generally engaged in this industry for more than 10 years, and their users have very rich experience, have a good understanding and knowledge of the quality and performance of products, suitable for the requirement of the customers will recommend price is a good product, choose a convenient and practical accessories.

- Q: What does T6 mean in aluminum alloy sections?

- The aluminum alloy heat treatment process of the broken bridge aluminum profile: the specific content is as follows:T6 is the deformation of Aluminum Alloy (distinguished from casting Aluminum Alloy) a heat treatment process, is "solid solution treatment (for steel in this process is called" quenching ", everyone should be very familiar with) + artificial aging process", of which the main factor is the solid solution temperature, quenching rate (determined by the quenching medium) and the aging temperature, holding time, time series (an aging or ageing).For different alloys, the same heat treatment code, such as T6, contains values that vary from one factor to another.This process is distinguished from what is commonly known as an annealing process.This process is the key to solving the problems of strength, plasticity, reasonable collocation (high strength and sufficient plasticity) and corrosion resistance.Without deformation of alloy Txxx processing, is absolutely can not be used as a structural material, will be mine, so please rest assured that your car frame (if not from the black hearted miners workshop) must have been processed.2014 aluminum alloy commonly used heat treatment state code has T6, T62, T651 (E), different product shape processing process is slightly different.My MOSSO car shelf is 7005 alloy, the usual process is T53 (V), do not write above also know.Handlebar and handlebar immediately 6061 aluminum alloy T6The above aluminum alloys are all foreign brands

- Q: What are the potential hazards or risks associated with the use of aluminum profiles in construction projects?

- <p>Safety concerns related to using aluminum profiles in construction include potential corrosion due to exposure to harsh weather conditions, risk of electrical conductivity which may lead to electrocution hazards, and the possibility of thermal expansion and contraction causing structural instability. Additionally, improper installation can lead to structural failure, and the lightweight nature of aluminum may not provide sufficient strength in load-bearing applications. It's crucial to ensure proper design, quality materials, and adherence to safety standards to mitigate these risks.</p>

- Q: How many tons of aluminum can be produced by a ton of aluminium ingots?

- Firstly, according to the requirements of a ton of aluminum ingot made of different aluminum alloy rods, concrete can output many aluminum rods must be based on the company's standard, but personally think that a ton of aluminum rod is absolutely not up to a ton of waste in the section product, because in the process of consumption, waste can not be calculated in the product section in.

- Q: What are the advantages of using aluminum profiles in the railway industry?

- There are several advantages of using aluminum profiles in the railway industry. Firstly, aluminum profiles are lightweight yet strong. This makes them ideal for use in various railway applications such as train carriages, windows frames, and structural components. The lighter weight of aluminum profiles helps to reduce the overall weight of the train, resulting in lower energy consumption and improved fuel efficiency. It also allows for increased payload capacity, enabling trains to carry more passengers or cargo. Secondly, aluminum profiles have excellent corrosion resistance. Trains are exposed to different weather conditions and environments, including rain, snow, and high humidity. The corrosion resistance of aluminum profiles ensures that they can withstand these conditions without deteriorating or losing their structural integrity. This translates to longer lifespan and reduced maintenance costs for railway operators. Another advantage of using aluminum profiles in the railway industry is their flexibility and versatility. Aluminum can be easily extruded into various shapes and sizes, allowing for customization and design flexibility. This enables manufacturers to create complex and intricate profiles that meet the specific requirements of railway applications. Additionally, aluminum profiles can be easily joined or assembled using various techniques, making them suitable for quick and efficient assembly during train manufacturing or maintenance. Furthermore, aluminum profiles are highly recyclable. With sustainability becoming increasingly important in the railway industry, aluminum's recyclability makes it an environmentally friendly choice. Aluminum can be recycled multiple times without losing its properties, reducing the demand for primary aluminum production and minimizing the environmental impact. Lastly, aluminum profiles offer aesthetic advantages. They can be finished with different coatings or anodized to enhance their appearance and provide additional protection against wear and tear. This allows for the creation of visually appealing train interiors and exteriors, contributing to a positive passenger experience. In conclusion, the advantages of using aluminum profiles in the railway industry include their lightweight yet strong nature, corrosion resistance, flexibility, recyclability, and aesthetic appeal. These benefits make aluminum profiles a preferred choice for various railway applications, contributing to improved performance, reduced costs, and enhanced sustainability in the industry.

- Q: Measuring 3 meters long aluminum profiles of the straightness, you have what good method? What is the maximum deviation value allowed by our industry? In addition to the platform measurement, and what are the economic and practical methods, our factory stalls are small. Consider input costs.

- For bending, twist test should be adopted according to the requirements of the platform, but in actual use, the platform used as a simple test tube can also be used to forming good Aluminum Alloy square or rectangular, note the tube before use, the first to confirm the test, can be used as a test platform.

Send your message to us

Extruded Aluminum Tubing Profiles - Aluminium D-Profile According to European Standards

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords