Aluminum Led Extrusion Profiles - Sandblasted Anodized Aluminium Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

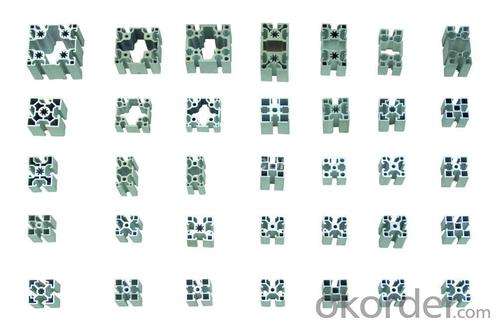

Aluminum Profile

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: Are there any regulations or standards that aluminum profiles must meet?

- Yes, there are several regulations and standards that aluminum profiles must meet in order to ensure their quality and safety. These regulations and standards vary depending on the specific application and industry, but some common ones include: 1. ISO Standards: The International Organization for Standardization (ISO) has developed various standards for aluminum profiles, such as ISO 9001 for quality management systems, ISO 14001 for environmental management systems, and ISO 9001 for occupational health and safety management systems. 2. ASTM International Standards: ASTM International provides standards for aluminum profiles used in construction, transportation, and other industries. These standards outline the chemical composition, mechanical properties, and dimensional tolerances that aluminum profiles must meet. 3. American National Standards Institute (ANSI) Standards: ANSI develops standards for aluminum profiles used in various applications. These standards cover aspects such as design, performance, and safety requirements. 4. European Standards (EN): In Europe, aluminum profiles must meet the requirements of the European Committee for Standardization (CEN). These standards define the characteristics, dimensions, and tolerances of aluminum profiles used in construction, aerospace, automotive, and other industries. 5. National Regulations: Many countries have their own regulations governing the use of aluminum profiles. These regulations may cover aspects such as fire safety, structural integrity, and environmental impact. It is important for manufacturers, suppliers, and users of aluminum profiles to adhere to these regulations and standards to ensure the quality, reliability, and safety of their products and applications. Compliance with these standards helps to maintain consistency, interoperability, and customer confidence in the use of aluminum profiles across various industries.

- Q: This question asks for guidance on selecting a dependable supplier for aluminum profiles, which are essential for various industries.

- <p>To choose a reliable supplier of aluminum profiles, consider the following: Check their industry experience and reputation. Look for certifications and quality management systems like ISO standards. Evaluate their product quality by requesting samples and conducting tests. Assess their delivery times and reliability. Ensure they have a wide range of profiles to meet diverse needs. Investigate customer reviews and testimonials for insights into their service. Finally, consider the cost-effectiveness of their products without compromising on quality.</p>

- Q: How do you cut and shape aluminum profiles?

- To cut and shape aluminum profiles, there are several methods you can use depending on the desired outcome and the tools you have available. Here are three common techniques: 1. Cutting with a hacksaw or miter saw: This is the most basic and accessible method. Using a hacksaw or a miter saw with an aluminum cutting blade, mark the desired length on the profile and carefully cut through it. Ensure you have a secure grip on the profile and make slow, steady cuts to avoid excessive vibration or the blade getting stuck. 2. Using a power saw or circular saw: For larger or thicker aluminum profiles, a power saw or circular saw with a specialized aluminum cutting blade will make the job faster and easier. Measure and mark the desired length on the profile, then secure it firmly in place. Using the power saw, slowly and steadily cut through the profile, ensuring you have a firm grip and maintaining control throughout the process. 3. Shaping with a file or grinder: Once the profile is cut to the desired length, you may need to shape or smooth the edges. This can be done using a file or grinder with an aluminum grinding wheel or sanding disc. Carefully work the file or grinder along the edges, shaping or smoothing them as needed. Take care not to apply too much pressure, as aluminum can heat up quickly and may distort or become damaged. Remember to wear appropriate safety gear, such as gloves and eye protection, when working with aluminum profiles. Additionally, it's always a good idea to practice on scrap pieces first to familiarize yourself with the techniques and tools before working on the final product.

- Q: Aluminum blackening formula

- Anodic oxidation of aluminum is aluminum or Aluminum Alloy anode to lead as cathode in sulfuric acid, oxalic acid, chromic acid and aqueous solution electrolysis, so that the surface oxide film. The anodic oxidation process is most widely used. Aluminum and Aluminum Alloy sulfuric acid anodizing oxidation film has high adsorption capacity, easy sealing alone or with colored more to improve the corrosion resistance of anodic oxide film thickness and appearance. The process is generally Aluminum Alloy sulfuric acid anodizing electrolyte has the advantages of simple operation, stable, cost is not high, the process is mature, but in sulfuric acid anodized process often unavoidable failure occurred, influence of oxide film quality. The following detailed analysis about the failure reasons, then give some preventive measures for your reference:Common faults and analysisAluminum Alloy products by sulfuric acid anodic oxidation, partial oxidation without touch, showing visible black spots or stripes, film drums or holes. The failure phenomenon of tumor is rare but has occurred.Dr. al website has detailed knowledge

- Q: Are aluminum profiles suitable for sports equipment?

- Sports equipment can be made using aluminum profiles, as they are lightweight and durable. Aluminum has a high strength-to-weight ratio, making it perfect for applications that require strength without excessive weight. Various sports equipment, including bicycles, golf clubs, baseball bats, tennis rackets, and even sports stadiums and arenas, commonly use aluminum profiles. The lightweight nature of aluminum allows athletes to handle the equipment easily, leading to better performance and less fatigue during sports activities. Moreover, aluminum's durability ensures that the equipment can endure intense use and last longer. The versatility of aluminum profiles also makes them suitable for sports equipment. They can be easily shaped, molded, and manipulated into different designs to meet specific performance requirements. This flexibility enables manufacturers to create equipment with desired characteristics, such as improved aerodynamics, better balance, or enhanced shock absorption. Furthermore, aluminum profiles have excellent corrosion resistance, which is especially crucial for sports equipment that may be exposed to moisture, sweat, or harsh environmental conditions. This property guarantees that the equipment remains functional and maintains its performance over time. In conclusion, aluminum profiles are a suitable choice for sports equipment because of their lightweight, durable, and versatile nature. With their high strength-to-weight ratio, they contribute to improved performance, reduced fatigue, and extended equipment lifespan.

- Q: How about the weight calculation of 180 series semi concealed curtain wall aluminum profile

- 180 series of semi curtain wall aluminum profile weight calculation, usually 15 kg per square meter.Aluminum plating process, which belongs to the coating technology it is pre plating and electroplating process steps to increase on the basis of conventional Ti process, aluminum is the process of the aqueous solution of salt and hydrochloric acid in the plating after activation of chemical treatment; electroplating bath composition including nickel sulfate, nickel chloride, boric acid, twelve alkyl sodium sulfate, saccharin, brightener, this process has the advantages of simple, practical and good effect, the titanium aluminum prepared by the hardness of the film is HV 1500, under the same conditions than the 22 carat gold plating wear 150 times, can be processed into various forms of gold color, color, black light series aluminum products.

- Q: This question asks if aluminum profiles can be utilized for constructing exterior walls or facades.

- <p>Yes, aluminum profiles can be used for exterior walls or facades. They are known for their durability, low maintenance, and resistance to weather conditions. Aluminum is lightweight, strong, and can be easily shaped into various designs, making it an ideal material for modern architecture. It also offers excellent thermal performance and can be combined with insulation to enhance energy efficiency. Additionally, aluminum profiles can be powder-coated or anodized to provide a protective finish and a wide range of color options, enhancing the aesthetic appeal of the building facade.</p>

- Q: How do aluminum profiles perform in blast-resistant structures?

- Due to their exceptional performance characteristics, aluminum profiles find wide application in blast-resistant structures. These profiles possess several advantages that render them suitable for such purposes. To begin with, aluminum profiles offer an excellent strength-to-weight ratio, enabling them to provide high structural integrity while maintaining a relatively low overall weight. This plays a crucial role in blast-resistant structures by minimizing explosion impact and potential damage. Additionally, aluminum profiles exhibit remarkable corrosion resistance, ensuring their durability in harsh environments. This becomes particularly significant in blast-resistant structures, where exposure to intense pressure waves, debris, and extreme temperatures may occur during an explosion. Moreover, aluminum profiles possess excellent energy absorption capabilities, effectively dissipating and absorbing blast-generated energy. Consequently, this reduces the impact on the structure and enhances its overall blast resistance. Such a feature plays a vital role in safeguarding occupants and preventing structural failure. Furthermore, aluminum profiles offer exceptional design flexibility, allowing architects and engineers to construct complex and innovative structures. This versatility empowers the creation of blast-resistant structures tailored to specific requirements and design constraints. In conclusion, aluminum profiles excel in blast-resistant structures due to their high strength-to-weight ratio, corrosion resistance, energy absorption capabilities, and design flexibility. These qualities establish them as the preferred choice for architects and engineers when designing structures capable of withstanding the forces generated by an explosion.

- Q: I have a disinfection cabinet to cut off a piece of aluminum to install the control board, how to cut? What tool to cut?

- The use of wire saw can be sawed, if you cannot use a wire saw, it can only be used to drill holes along the need the position of the drill hole, finally use a tool to trim it to the edge.

- Q: Can aluminum profiles be used for signage?

- Signage can indeed utilize aluminum profiles. Aluminum, a material known for its versatility and durability, is commonly utilized in various signage applications. It boasts numerous advantages, including its lightweight nature, resistance to corrosion, and ease of manipulation. Aluminum profiles can be effortlessly shaped into diverse forms and sizes, rendering them suitable for a vast array of signage needs. Furthermore, these profiles can be powder coated or painted to attain the desired color and finish, thereby enhancing the signage's overall appearance. Notably, aluminum is an environmentally friendly option for signage projects as it is highly recyclable, contributing to its sustainability. All in all, due to their durability, versatility, and aesthetic appeal, aluminum profiles remain a favored choice for signage projects.

Send your message to us

Aluminum Led Extrusion Profiles - Sandblasted Anodized Aluminium Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords