Aluminum Insulation Sheets - PVC Aluminium Foil Laminating Extruder PE Coated

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of PVC aluminium Foil Laminating Extruder PE Coated Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the PVC aluminium Foil Laminating Extruder PE Coated:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

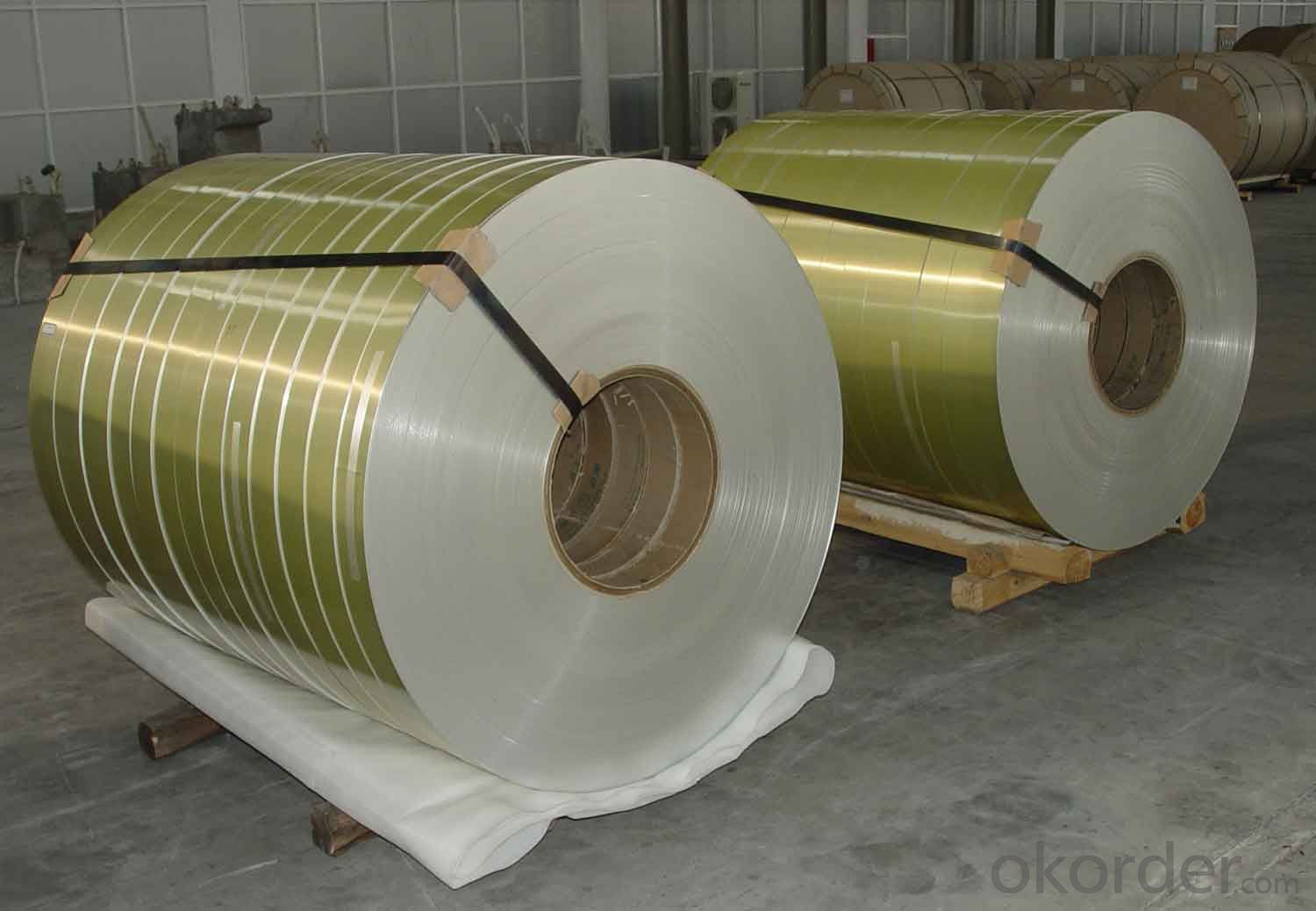

Images of PVC aluminium Foil Laminating Extruder PE Coated:

Aluminium Pre-painted Coil Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: How do aluminum sheets perform in terms of heat reflectivity?

- Aluminum sheets have excellent heat reflectivity properties. They efficiently reflect heat and radiation, making them suitable for various applications that require heat insulation or management.

- Q: could aluminum sheet be attracted by magnet?

- no, it couldn't.

- Q: Can aluminum sheets be used for water tanks?

- Yes, aluminum sheets can be used for water tanks. Aluminum is a corrosion-resistant material and is commonly used in the construction of water tanks due to its durability and ability to withstand harsh weather conditions.

- Q: Are 101 aluminum sheets suitable for marine environments?

- Indeed, marine environments are indeed suitable for 101 aluminum sheets. Recognized for its exceptional corrosion resistance, 101 aluminum is a high-strength alloy that proves to be perfect for marine applications. It can endure the harsh circumstances of saltwater, including exposure to salt spray and water immersion, without undergoing corrosion or deterioration. Furthermore, 101 aluminum possesses commendable weldability and formability, enabling it to be effortlessly shaped into a multitude of marine components like boat hulls, decks, and equipment. The strength, durability, and corrosion resistance of 101 aluminum sheets establish them as a dependable option for marine environments.

- Q: Can aluminum sheets be used for solar panel frames?

- Yes, aluminum sheets can be used for solar panel frames. Aluminum is a popular choice for solar panel frames due to its lightweight, corrosion-resistant, and durable properties. It allows for easy installation, reduces overall weight, and provides structural support for the solar panels. Additionally, aluminum frames can withstand various weather conditions and ensure the longevity of the solar panel system.

- Q: Are 101 aluminum sheets suitable for automotive applications?

- Yes, 101 aluminum sheets are suitable for automotive applications. 101 aluminum is a high-strength alloy that offers good formability, corrosion resistance, and excellent weldability. These properties make it a popular choice for various automotive components such as body panels, heat shields, and structural parts. Additionally, 101 aluminum sheets are lightweight, which helps improve fuel efficiency and overall vehicle performance. Overall, 101 aluminum sheets are well-suited for automotive applications due to their strength, formability, corrosion resistance, weldability, and lightweight characteristics.

- Q: What are the different methods for bending aluminum sheets?

- There are several methods for bending aluminum sheets. The most common methods include using a brake press, roll bending, and stretch forming.

- Q: Can aluminum sheets be used for elevator interiors?

- Indeed, elevator interiors can certainly be constructed using aluminum sheets. Aluminum has gained significant popularity as a material of choice for elevator interiors due to its multitude of advantageous qualities. Its lightweight nature, durability, and resistance to corrosion render it highly suitable for long-term utilization in elevator applications. With ease, aluminum sheets can be skillfully fabricated and shaped to perfectly fit the dimensions and design specifications of elevator interiors. Furthermore, aluminum can be enhanced with various types of coatings or finishes, such as anodizing or powder coating, to not only augment its aesthetic appeal but also provide additional protection. Overall, aluminum sheets represent a practical and widely utilized option for elevator interiors within the industry.

- Q: Are aluminum sheets suitable for aircraft panels?

- Yes, aluminum sheets are suitable for aircraft panels. Aluminum is a widely used material in the aerospace industry due to its excellent strength-to-weight ratio, corrosion resistance, and formability. It offers durability and structural integrity while keeping the weight of the aircraft relatively low. Aluminum sheets are commonly used for constructing aircraft panels, providing a reliable and efficient solution for aerospace applications.

- Q: How do aluminum sheets perform in terms of thermal expansion and contraction?

- Aluminum sheets possess a relatively high coefficient of thermal expansion, causing them to expand and contract more than most other materials when subjected to heat or cold. The coefficient of thermal expansion for aluminum is approximately 23 x 10^-6 per degree Celsius. Consequently, for each degree Celsius rise in temperature, aluminum expands by 23 millionths of its original size. This thermal expansion and contraction characteristic of aluminum renders it suitable for various applications where temperature fluctuations are anticipated. For example, in the construction industry, aluminum sheets are commonly utilized for roofing and cladding purposes. These sheets can endure the thermal stresses resulting from changing temperatures without experiencing significant warping or distortion. Additionally, this particular attribute of aluminum makes it an ideal choice for the production of items such as cookware and heat sinks. Aluminum cookware heats up rapidly and evenly due to its high thermal conductivity, while expanding uniformly to prevent warping or deformation when exposed to heat. Similarly, aluminum heat sinks effectively dissipate heat generated by electronic components as they can accommodate thermal expansion without compromising their structural integrity. However, it is important to acknowledge that although aluminum sheets possess favorable thermal expansion and contraction properties, extreme temperature changes can still result in some dimensional alterations. Therefore, careful consideration of the expected temperature variations is essential when designing and utilizing aluminum sheets to ensure their optimal performance and durability.

Send your message to us

Aluminum Insulation Sheets - PVC Aluminium Foil Laminating Extruder PE Coated

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords