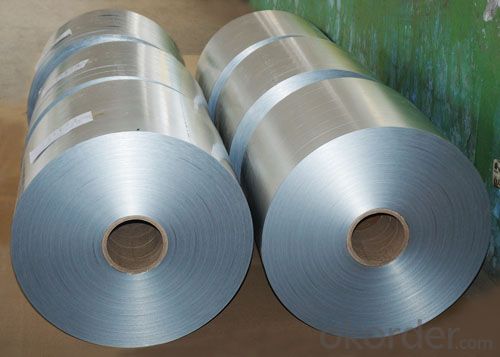

Aluminum in Coil Form - 5052 Temper H32 0.8mm to 1mm Thick 1000mm Width Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

5052 Temper H32 0.8mm 1mm Thick 1000mm Width Aluminum Coil

1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above

3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment.

6xxx series represents 6061 mainly contain magnesium and silicon of two elements, so focused on the 4000 series and the advantages of the 5000 series 6061 is a cold treatment aluminum forging products, apply to fight against corrosion, oxidizing demanding applications.

Description

item | 1050 1060 1100 3003 Aluminum coil | |

Standard | GB/T3190-2008,GB/T3880-2006,ASTM B209,JIS H4000-2006,etc | |

Material | 1060,1050,1100 3003,3103,3004,3005,3105 5052, 5454,5754 | |

Size | Thickness | 0.5mm-3.5mm |

Width | 800-1500mm | |

Weight/Roll | About 1.5MT/3MT | |

Quality control | Mill Test Certificate is supplied with shipment, Third Part Inspection is acceptable. | |

Surface | Bright, polished, hair line, brush, checkered, embossed, etc | |

Trade terms | Price term | ,FOB, CNF, CIF, etc |

Payment Term | TT,L/C | |

MOQ | 2MT | |

20 GP Capacity | About 20-25MT | |

Delivery time | 1.The products will delivery immediately after receiving the payment. 2.According to the order quantity, prompt delivery. | |

Export to | Ireland,Singapore,Indonesia,Ukraine,Spain,Canada,USA,Brazil,Thailand,Korea,Iran,India,Egypt,Kuwait, Oman,Viet Nam, South Africa, Dubai, Russia, etc | |

Package | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | |

Application | 1)Further making utensil.2)Solar reflective film3)The appearance of the building4)Interior decorating:ceilings,walls,etc.5)Furniture cabinets6)Elevator decoraction7)Signs,nameplate,bags making.8)Decoration inside and outside the car9)Household appliances:refrigerators,microwave ovens,audio equipment,etc.10)The consumer electronics:mobile phones,digital cameras,MP3,etc. | |

- Q: What are some common types of aluminum coils used in various industrial applications?

- <p>Yes, there are several types of aluminum coils commonly used in industry. These include: 1) Plain aluminum coils, which are used in packaging and construction. 2) Embossed aluminum coils, utilized for decorative purposes and in the automotive industry. 3) Painted aluminum coils, often used in building materials and appliances. 4) Galvanized aluminum coils, which are corrosion-resistant and used in exterior applications. 5) Heat-treated aluminum coils, known for their strength and used in aerospace and automotive parts. Each type serves specific purposes based on the properties of the aluminum and the coatings or treatments applied.</p>

- Q: What is the typical hardness of aluminum coils?

- The hardness of aluminum coils can vary depending on different factors, such as the composition of the alloy, the process of tempering, and the intended use. Manufacturers produce aluminum coils with different levels of hardness to meet various needs and requirements. Aluminum coils are available in different tempers, including soft, half-hard, and full-hard. Soft aluminum coils have low hardness and are highly malleable, making them suitable for applications that require easy shaping, such as packaging and wrapping materials. Half-hard aluminum coils are moderately hardened and offer a balance between formability and strength, making them suitable for applications like roofing and siding. Full-hard aluminum coils have the highest hardness and provide excellent strength, making them ideal for applications that require structural integrity, such as automotive parts and construction materials. To determine the specific hardness of aluminum coils, various testing methods can be used, such as Rockwell hardness, Vickers hardness, or Brinell hardness. These tests measure the resistance of the aluminum surface to indentation and provide a numerical value indicating the material's hardness. However, it is important to consult the manufacturer or supplier for the specific hardness values, as they can vary depending on the specific alloy and temper of the aluminum coil.

- Q: What are the different coil recoiling options available for aluminum coils?

- Depending on the specific requirements and desired outcomes, there are various options available for recoiling aluminum coils. One possibility is to use the oscillate recoiling method, which involves winding the aluminum coil in a zigzag pattern. This technique can help reduce coil set and improve flatness, making it ideal for applications where a flat, smooth surface is crucial. Another option is the traverse winding method, where the aluminum coil is wound back and forth in a controlled manner. This technique helps evenly distribute tension across the coil, minimizing the risk of coil breaks and ensuring consistent performance. Additionally, there are choices for coil slitting and rewinding. Slitting involves cutting the aluminum coil into narrower strips, which can be rewound into smaller coils. This option is commonly employed when smaller coil sizes are necessary for specific applications. Moreover, some recoiling options include coil rewinding with tension control systems. These systems ensure that the tension applied during rewinding is controlled and consistent, preventing overstretching or deformation of the aluminum coil. In conclusion, the selection of recoiling options for aluminum coils depends on factors such as desired surface finish, coil size requirements, and specific application needs. Manufacturers and processors of aluminum coils can offer guidance and expertise in selecting the most suitable recoiling option based on these considerations.

- Q: Are there any certifications or standards for aluminum coils?

- Yes, there are various certifications and standards for aluminum coils. Some notable ones include the ASTM International standards, such as ASTM B209 for aluminum and aluminum-alloy sheet and plate, and ASTM B221 for aluminum-alloy extruded bars, rods, wire, profiles, and tubes. Additionally, the Aluminum Association provides industry guidelines and certifications, such as the Aluminum Association Registration for Aluminum Coil Production Facilities. These certifications and standards ensure that aluminum coils meet specific quality, performance, and safety requirements.

- Q: What is the reason for the grooves that go around the circumference of a tin/aluminium can? It can't be for grip because they're covered with paper anyway and i don't think it would make much difference.

- Strength.

- Q: Are there any specific certifications or qualifications required for aluminum coil suppliers?

- Yes, there are specific certifications and qualifications that are important for aluminum coil suppliers. One of the key certifications for aluminum coil suppliers is the ISO 9001 certification, which ensures that the supplier has implemented a quality management system and meets the international standards for quality. This certification indicates that the supplier has effective quality control processes, consistent product performance, and customer satisfaction. Another important qualification for aluminum coil suppliers is the AS9100 certification, specifically for suppliers serving aerospace industries. This certification ensures that the supplier has met the quality management system requirements specific to the aerospace industry, including stringent quality control, traceability, and compliance with industry standards. Additionally, aluminum coil suppliers may also need to comply with specific industry standards such as the American Society for Testing and Materials (ASTM) standards or the European Union's REACH regulations for chemical substances. These standards ensure that the supplier's products meet the required specifications and are safe for use in various applications. Furthermore, some aluminum coil suppliers may possess specialized certifications or qualifications related to specific industries or applications. For example, suppliers serving the automotive industry may hold certifications such as the International Automotive Task Force (IATF) 16949 certification, which demonstrates their ability to meet the demanding requirements of automotive manufacturers. Overall, while specific certifications and qualifications may vary depending on the industry and application, aluminum coil suppliers should have certifications such as ISO 9001 and industry-specific certifications to ensure their products meet the required quality standards and comply with relevant regulations.

- Q: What are the different grades of aluminum used in coils?

- There are several different grades of aluminum commonly used in coils, including 1100, 3003, 5052, and 6061. Each grade has its own unique characteristics and properties, making them suitable for different applications. For example, 1100 aluminum is known for its excellent corrosion resistance and high thermal conductivity, making it ideal for heat exchangers and fins. On the other hand, 5052 aluminum offers good formability and moderate strength, making it commonly used in automotive and marine applications. Lastly, 6061 aluminum is a versatile grade with excellent strength-to-weight ratio, making it suitable for structural components and aerospace applications.

- Q: What is the flexural strength of aluminum coils?

- The flexural strength of aluminum coils varies depending on the specific grade and thickness of the aluminum used. Generally, aluminum coils have good flexural strength due to the inherent properties of aluminum, which is known for its high strength-to-weight ratio.

- Q: What is the typical lifespan of an aluminum coil?

- The typical lifespan of an aluminum coil can vary depending on factors such as usage, maintenance, and environmental conditions. However, with proper care and regular maintenance, an aluminum coil can last anywhere from 20 to 30 years or even longer. This lifespan can be extended by keeping the coil clean, ensuring proper ventilation to prevent moisture buildup, and addressing any damages or issues promptly. Additionally, factors such as exposure to harsh weather conditions, chemicals, or corrosive environments can impact the lifespan of an aluminum coil. It is important to consult with manufacturers or industry professionals for specific information regarding the expected lifespan of a particular aluminum coil in different applications.

- Q: What are the different coil packaging options for aluminum coils?

- The different coil packaging options for aluminum coils include wooden crates, steel frames, cardboard boxes, plastic wrapping, and pallets. These packaging options are chosen based on factors such as the size and weight of the coils, transportation requirements, and protection needed during storage or shipment.

Send your message to us

Aluminum in Coil Form - 5052 Temper H32 0.8mm to 1mm Thick 1000mm Width Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords