Wide Aluminum Coil - Corrosion Inspection 5052 H32 Aluminium Gutter Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Corrosion Inspection 5052 H32 Aluminium Gutter Coil

l Product Introduction

Aluminium Coil is widely used in manufacturing aluminum thin sheet and aluminum foil. It is suitable for further machining with original standard quality. It is easy to be controlled and be manufactured to according to requirements.

l Product Specification

| Main Specification | ||||||||

| Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) | |||||||

| AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | ||||||||

| AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | ||||||||

| AA8xxx(AA8011, AA8006 etc.) | ||||||||

| Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 | |||||||

| Thickmess | 0.01mm-100mm | |||||||

| Width | 30mm-1700mm | |||||||

| Standard | GB/T 3880-2006/ASTM | |||||||

| Special specification is available on customer's requirement | ||||||||

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advanced payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium coil is one of the popular product in the market of CNBM. With advanced technology and equipment, CNBM has sold its hight quality color coated aluminium coil to the world.

l CNBM World Wide

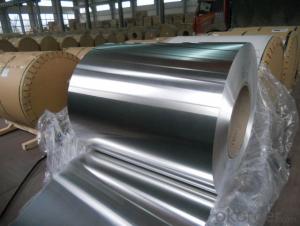

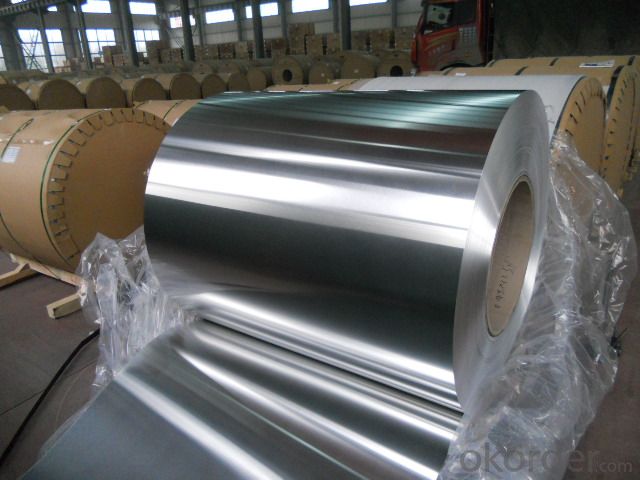

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: Are aluminum coils suitable for coil slitting applications?

- Yes, aluminum coils are suitable for coil slitting applications. Aluminum is a versatile and lightweight material that can be easily processed and slit into various widths, making it ideal for industries like automotive, construction, and packaging. Its high strength-to-weight ratio and corrosion resistance make aluminum coils a reliable choice for coil slitting applications.

- Q: Can aluminum coils be used for food processing conveyor systems?

- Yes, aluminum coils can be used for food processing conveyor systems. Aluminum is a durable and lightweight material that is resistant to corrosion, making it suitable for food processing environments. Additionally, aluminum is non-toxic and does not react with food, ensuring the safety and quality of the processed products.

- Q: Explain how aluminum coils impact the manufacturing process.

- <p>Aluminum coils significantly affect the production process by offering versatility and efficiency. They are easily formed, cut, and shaped, which streamlines manufacturing. Their lightweight nature reduces the energy consumption in transportation and handling. Additionally, aluminum coils' corrosion resistance and durability reduce waste and the need for frequent replacements, enhancing sustainability. They also contribute to the production of various products, such as automotive parts, construction materials, and packaging, by providing a consistent and high-quality material.</p>

- Q: The export aluminum volume is CIF. If there is no insurance policy, how will the customs premium be collected?

- The customs will not charge your premium the premium you can write but if you are a refund if there will be some impact because of the tax rebate minus the freight and insurance premium so you consider the premium but you can write less Never mind if you need shipping or shipping insurance declaration business can contact me oh

- Q: Can aluminum coils be used in the production of electronic components?

- Yes, aluminum coils can be used in the production of electronic components. Aluminum is a commonly used material due to its lightweight, conductivity, and corrosion resistance properties. It is often used in electronic devices such as capacitors, inductors, and transformers.

- Q: This question asks about the common applications of aluminum coil in everyday life.

- <p>Aluminum coil is widely used in daily life due to its lightweight, corrosion resistance, and thermal conductivity. It's commonly used in construction for roofing and siding, in the automotive industry for car parts, and in the packaging industry for food and beverage cans. It's also used in electrical applications like transformers and wiring due to its good conductivity. In the kitchen, aluminum foil is used for cooking and food storage, and in the HVAC industry for heat exchangers and ductwork. Its versatility makes aluminum coil an essential material in many industries and everyday applications.</p>

- Q: helicopters rotorblades are made of honeycombed aluminum to give them strength, so isn't it a good idea for automakers to use the same technology to strengthen the frames of autos to make them lesslikely to cave in during a side impact auto accident?

- Cost is everything - if they get enough design margin from a single sheet that is the choice. Especially in fabrication costs. Besides cars are designed to crumple and a honeycomb structure may be too strong to dissipate crash forces as the body deforms in an accident. Aerospace uses that structure for light-weigh performance and can literally eat the extra cost.

- Q: This question asks for a comparison of the pros and cons of utilizing steel coils in construction projects.

- <p>Advantages of using steel coils in construction include their high strength and durability, which allows for the creation of robust structures. They are also resistant to corrosion and can withstand harsh weather conditions. Steel coils are versatile and can be easily shaped and welded, making them suitable for a variety of construction applications. Additionally, they are recyclable, contributing to sustainability efforts. Disadvantages include the initial high cost of steel coils compared to some other materials, and the potential for rust if not properly maintained. Steel structures may also require more frequent inspections and maintenance due to the risk of corrosion over time, especially in coastal or humid environments.</p>

- Q: Inquiry about the feasibility of using a laser for cutting aluminum coils.

- <p>Yes, you can use a laser to cut aluminum coils. Laser cutting is a versatile process that can be used on a variety of materials, including aluminum. However, it's important to note that the type of laser and the specific settings should be appropriate for aluminum. Fiber lasers or CO2 lasers are commonly used for metal cutting, including aluminum. The process requires careful control of the laser's power, speed, and focus to achieve clean and precise cuts. Additionally, because aluminum is a reflective metal, special considerations such as the use of a protective cover gas and proper nozzle management are necessary to prevent damage to the laser equipment and to ensure the quality of the cut.</p>

- Q: Can aluminum coils be custom-made to specific requirements?

- Yes, aluminum coils can be custom-made to specific requirements. Aluminum coils are versatile and can be tailored to meet a wide range of specifications and applications. Manufacturers can customize the dimensions, thickness, width, and length of the coil to accommodate specific requirements. Additionally, various surface finishes, such as embossed patterns or coatings, can be applied to enhance the appearance or improve functionality. Customization of aluminum coils allows for precise matching of specific needs in industries such as construction, transportation, aerospace, and many others.

Send your message to us

Wide Aluminum Coil - Corrosion Inspection 5052 H32 Aluminium Gutter Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords