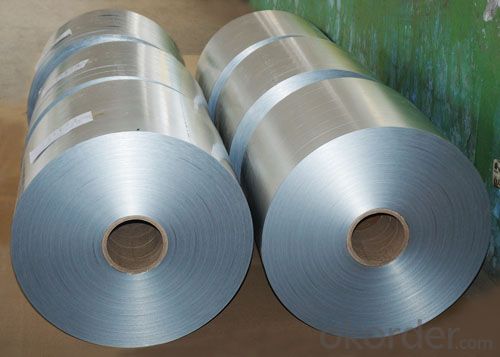

2024 Aluminum Coil Strip 5052 Temper H32 0.8mm to 1.5mm Thick 900mm to 1000mm Width

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminum Coils 5052 Temper H32 0.8mm 1.5mm Thick 1000mm Width

1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above

3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment.

6xxx series represents 6061 mainly contain magnesium and silicon of two elements, so focused on the 4000 series and the advantages of the 5000 series 6061 is a cold treatment aluminum forging products, apply to fight against corrosion, oxidizing demanding applications.

Description

item | 1050 1060 1100 3003 Aluminum coil | |

Standard | GB/T3190-2008,GB/T3880-2006,ASTM B209,JIS H4000-2006,etc | |

Material | 1060,1050,1100 3003,3103,3004,3005,3105 5052, 5454,5754 | |

Size | Thickness | 0.5mm-3.5mm |

Width | 800-1500mm | |

Weight/Roll | About 1.5MT/3MT | |

Quality control | Mill Test Certificate is supplied with shipment, Third Part Inspection is acceptable. | |

Surface | Bright, polished, hair line, brush, checkered, embossed, etc | |

Trade terms | Price term | ,FOB, CNF, CIF, etc |

Payment Term | TT,L/C | |

MOQ | 2MT | |

20 GP Capacity | About 20-25MT | |

Delivery time | 1.The products will delivery immediately after receiving the payment. 2.According to the order quantity, prompt delivery. | |

Export to | Ireland,Singapore,Indonesia,Ukraine,Spain,Canada,USA,Brazil,Thailand,Korea,Iran,India,Egypt,Kuwait, Oman,Viet Nam, South Africa, Dubai, Russia, etc | |

Package | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | |

Application | 1)Further making utensil.2)Solar reflective film3)The appearance of the building4)Interior decorating:ceilings,walls,etc.5)Furniture cabinets6)Elevator decoraction7)Signs,nameplate,bags making.8)Decoration inside and outside the car9)Household appliances:refrigerators,microwave ovens,audio equipment,etc.10)The consumer electronics:mobile phones,digital cameras,MP3,etc. | |

- Q: What are the common alloys used in aluminum coil production?

- The common alloys used in aluminum coil production are 3003, 3105, 5052, and 6061.

- Q: Are aluminum coils resistant to fire?

- Aluminum coils are widely recognized as being fire-resistant. They possess a high melting point of 660 degrees Celsius, which is considerably higher than the typical temperature of most household fires. Consequently, aluminum coils are a favored choice for diverse applications requiring fire resistance, including the construction of buildings, electrical systems, and automotive components. Moreover, aluminum exhibits low flammability and does not emit toxic fumes when exposed to fire, further heightening its fire-resistant characteristics. Nonetheless, it is vital to acknowledge that the fire resistance of aluminum coils may vary depending on the specific alloy employed and the thickness of the coil. Hence, it is always advisable to seek advice from experts or adhere to industry standards to guarantee the implementation of appropriate fire safety precautions.

- Q: I take an extracurricular aircraft class, and I got the okay to take some old painted sheet aluminum for another project I'm working on. The problem is, what I'm using it for I need bare aluminum. I heard around that air crafts are painted with something that regular (store-bought) paint stripper can't remove. Is this true? I am aware of the fact that stripping something like that will result in a toxic paint sludge, so I've taken precautions for that. I just need to know if heavy-duty paint stripper from Home Depot will do the job. Thanks :)

- As above, an automotive shop might be able to help you with the correct stripper. If you can find someone who does aircraft finishing, he might help you. A lot of aviation type finishes (Imron, for example) are used in upper end automotive shops for exclusive finishing. You might get some help there. I would be careful about using ordinary strippers on aircraft aluminium. If your project is not going to fly, you would be safe. You might scratch the finish on your sheet though, getting the old paint off. If your project is going to fly, you need to use the correct process. It seems to me that (some time ago), I have heard of a sandblast process, using crushed walnut shells rather than sand, to remove paint from aircraft. Failing all that, you can try a commercial stripper on a small corner of your aluminium sheet to see what it does. Whatever you do, good luck, and have fun. It sounds to me like you could turn this into a research project all by itself.

- Q: What are the potential applications of brushed aluminum coils?

- Brushed aluminum coils have a wide range of potential applications across various industries. The distinct brushed finish of these coils makes them an attractive choice for both aesthetic and functional purposes. Here are some potential applications: 1. Architectural applications: Brushed aluminum coils can be used in architectural projects such as building facades, interior wall cladding, and decorative elements. The brushed finish adds a sleek and modern look, enhancing the overall design of the structure. 2. Automotive industry: Brushed aluminum coils can be used in the automotive industry for various purposes. They can be used for interior trim, such as dashboard panels, door handles, and decorative accents. The brushed finish adds a luxurious touch to the interior of vehicles. 3. Electronics and appliances: These coils can be used in the manufacturing of electronic devices and appliances. They are commonly used for the production of laptop casings, smartphone covers, and household appliances like refrigerators, ovens, and microwave panels. The brushed finish provides a stylish and durable surface. 4. Signage and displays: Brushed aluminum coils are often used in signage and display applications. They can be used for creating outdoor and indoor signs, channel letters, and exhibition displays. The brushed finish gives these signs a professional and eye-catching appearance. 5. Furniture and interior design: Brushed aluminum coils can be utilized in the furniture industry for various purposes. They are commonly used for creating furniture pieces like tables, chairs, and cabinets. The brushed finish adds a contemporary and sophisticated touch to the furniture design. 6. Packaging industry: Brushed aluminum coils can also find applications in the packaging industry. They can be used for packaging of high-end products like perfumes, cosmetics, and premium food items. The brushed finish gives the packaging a premium and luxurious appearance. 7. Industrial applications: These coils can be used in various industrial applications, such as manufacturing equipment, machinery, and industrial tools. The brushed finish provides durability, corrosion resistance, and a professional appearance. Overall, the potential applications of brushed aluminum coils are vast and diverse. From architecture to automotive, electronics to furniture, and packaging to industrial sectors, their versatility, durability, and aesthetic appeal make them a popular choice in multiple industries.

- Q: Yep a slogan...the element Aluminum

- Aluminum, unlucky # 13. or...Aluminum, fun to say-hard to chew. Aluminum says, stop staring at my cans. I 3 recycling.

- Q: How do aluminum coils contribute to increased structural stability?

- Aluminum coils contribute to increased structural stability in several ways. Firstly, aluminum as a material is highly durable and has excellent strength-to-weight ratio. This means that even though aluminum coils are lightweight, they offer superior strength and stability, making them an ideal choice for structural applications. Additionally, aluminum coils are corrosion-resistant, which is crucial for maintaining structural integrity over time. Unlike other metals, aluminum does not rust or deteriorate easily, even in harsh environmental conditions. This corrosion resistance ensures that the coils will remain structurally sound and reliable for extended periods. Moreover, aluminum coils have high thermal conductivity, which allows for efficient heat transfer. This characteristic is essential for structures exposed to temperature variations, as it helps to distribute and dissipate heat evenly, preventing any potential damage due to thermal expansion or contraction. Another significant advantage of aluminum coils is their flexibility. Aluminum is a malleable material that can be easily bent, shaped, and formed into various configurations. This flexibility allows for more intricate designs and enables the coils to adapt to different structural requirements, enhancing overall stability. Furthermore, aluminum is a non-combustible material, making it a safe choice for structural applications. In the event of a fire, aluminum coils will not contribute to the spread of flames, thus maintaining the integrity of the structure and ensuring the safety of occupants. In conclusion, aluminum coils contribute to increased structural stability through their durability, corrosion resistance, thermal conductivity, flexibility, and fire-resistant properties. These characteristics make them a reliable and efficient choice for a wide range of structural applications, providing long-lasting stability and safety.

- Q: I heard that one pound of aluminum pop tabs are worth more then a pound of aluminum pop cans. Is this true? Thank you.

- I Think So Because clean aluminum is easier to handle because they don't have to wash it like unclean aluminum.

- Q: Are aluminum coils suitable for low-maintenance applications?

- Indeed, low-maintenance applications are well-suited for the use of aluminum coils. Renowned for its strength and ability to resist corrosion, aluminum proves to be an exceptional selection for applications that demand minimal upkeep. Unlike alternative materials like steel, aluminum coils remain free from rust and do not necessitate regular painting to preserve their aesthetic appeal. Furthermore, the lightweight nature of aluminum facilitates effortless installation and handling, particularly in low-maintenance scenarios where frequent maintenance may prove impractical or undesirable. Ultimately, aluminum coils serve as a dependable and low-maintenance solution for a range of applications.

- Q: How are aluminum coils used in the production of heat sinks?

- The excellent thermal conductivity and malleability of aluminum coils make them indispensable in the production of heat sinks. Heat sinks are designed to dissipate excess heat from electronic components like processors, integrated circuits, and power transistors. By using aluminum coils in the manufacturing of heat sinks, several key advantages can be gained. First and foremost, aluminum coils possess high thermal conductivity, enabling efficient heat transfer from electronic components to heat sinks. This is crucial for maintaining optimal operating temperatures and preventing performance degradation or permanent damage caused by excess heat. The high thermal conductivity of aluminum ensures quick dissipation of heat away from electronic components, preventing overheating. Secondly, aluminum coils are highly malleable, making them easy to shape and mold into various heat sink designs. Heat sinks come in different sizes and shapes, with the most common being finned heat sinks. Fins on the heat sink increase surface area, facilitating greater heat dissipation. Aluminum coils can be easily formed into these fin shapes, enabling effective heat release into the surrounding environment. Furthermore, aluminum coils are lightweight and corrosion-resistant, making them ideal for use in heat sinks. The lightweight nature of aluminum ensures that heat sinks do not add significant weight to electronic devices, which is especially important in applications with weight restrictions, such as aerospace or portable electronics. Moreover, the corrosion-resistant properties of aluminum guarantee the durability and longevity of heat sinks, even in harsh environments. In conclusion, aluminum coils are vital components in the production of heat sinks due to their high thermal conductivity, malleability, lightweight, and corrosion resistance. By incorporating aluminum coils into the manufacturing process of heat sinks, efficient heat dissipation and improved performance of electronic components can be achieved, ultimately extending the lifespan of electronic devices.

- Q: Can aluminum coils be used in the production of solar panels?

- Yes, aluminum coils can be used in the production of solar panels. Aluminum is a lightweight and durable material that offers various benefits for solar panel manufacturing. It is highly conductive and has excellent thermal properties, allowing for efficient heat dissipation. Additionally, aluminum is resistant to corrosion, which is crucial for solar panels as they are exposed to various weather conditions. Moreover, aluminum is a cost-effective material, making it a popular choice in the solar industry. Overall, using aluminum coils in the production of solar panels helps to enhance their performance, longevity, and cost-effectiveness.

Send your message to us

2024 Aluminum Coil Strip 5052 Temper H32 0.8mm to 1.5mm Thick 900mm to 1000mm Width

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords