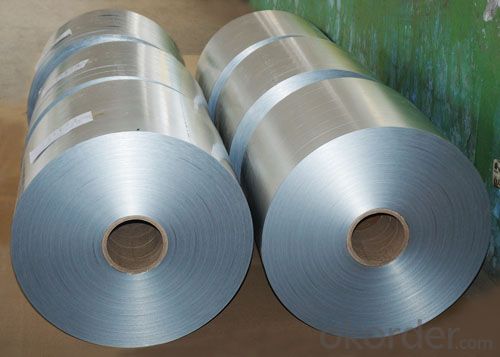

Painted Aluminum Coil - 5052 Temper H24 0.8mm to 1mm Thick 1000mm Width Aluminum Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

5052 Temper H24 0.8mm 1mm Thick 1000mm Width Aluminum Roll

1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above

3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment.

6xxx series represents 6061 mainly contain magnesium and silicon of two elements, so focused on the 4000 series and the advantages of the 5000 series 6061 is a cold treatment aluminum forging products, apply to fight against corrosion, oxidizing demanding applications.

Description

item | 1050 1060 1100 3003 Aluminum coil | |

Standard | GB/T3190-2008,GB/T3880-2006,ASTM B209,JIS H4000-2006,etc | |

Material | 1060,1050,1100 3003,3103,3004,3005,3105 5052, 5454,5754 | |

Size | Thickness | 0.5mm-3.5mm |

Width | 800-1500mm | |

Weight/Roll | About 1.5MT/3MT | |

Quality control | Mill Test Certificate is supplied with shipment, Third Part Inspection is acceptable. | |

Surface | Bright, polished, hair line, brush, checkered, embossed, etc | |

Trade terms | Price term | ,FOB, CNF, CIF, etc |

Payment Term | TT,L/C | |

MOQ | 2MT | |

20 GP Capacity | About 20-25MT | |

Delivery time | 1.The products will delivery immediately after receiving the payment. 2.According to the order quantity, prompt delivery. | |

Export to | Ireland,Singapore,Indonesia,Ukraine,Spain,Canada,USA,Brazil,Thailand,Korea,Iran,India,Egypt,Kuwait, Oman,Viet Nam, South Africa, Dubai, Russia, etc | |

Package | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | |

Application | 1)Further making utensil.2)Solar reflective film3)The appearance of the building4)Interior decorating:ceilings,walls,etc.5)Furniture cabinets6)Elevator decoraction7)Signs,nameplate,bags making.8)Decoration inside and outside the car9)Household appliances:refrigerators,microwave ovens,audio equipment,etc.10)The consumer electronics:mobile phones,digital cameras,MP3,etc. | |

- Q: What are the different grades of aluminum used in coil manufacturing?

- The different grades of aluminum commonly used in coil manufacturing include 1100, 3003, and 5052. These grades vary in their chemical composition, mechanical properties, and suitability for various applications.

- Q: How do I deal with too much aluminum powder when the aluminum strips are divided?

- For example, the wind speed control did not meet the requirements, or not in accordance with the explosion-proof ventilation system requirements set, including pipeline setting, setting, filter series parallel is the selection of explosion-proof, whether Mars and extinguishing measures.

- Q: My mom was being an idiot and used the steel spatula to scrape the cookies off an aluminum cookie sheet. Now there are small bits of aluminum on the bottom of the cookies. I just ate a few of them (5) before i noticed it, should I be worried?

- If it's only a little bit then it will just not be digested and pass through your body and come out your rear end. It's fine, as long as you don't swallow something like a ball-bearing.

- Q: How do aluminum coils contribute to the durability of roofs and facades?

- The durability of roofs and facades is greatly enhanced by aluminum coils, thanks to their inherent properties and design characteristics. Firstly, aluminum's resistance to corrosion makes it an ideal material for roofs and facades that are constantly exposed to harsh weather conditions. This corrosion resistance ensures that the coils remain unaffected by moisture, UV rays, and extreme temperatures, thus extending the lifespan of the entire roofing or facade system. Moreover, aluminum coils provide structural integrity to roofs and facades while being lightweight. This lightweight nature simplifies the installation process and reduces the load on the building's structure, which is particularly advantageous for larger structures. Despite their lightness, aluminum coils have high tensile strength, enabling them to withstand significant loads and pressure without warping or deforming. This strength enhances the overall stability and durability of the roof or facade, ensuring resistance against external forces like wind, snow, and hail. Furthermore, aluminum coils are highly malleable, allowing for easy customization during the manufacturing process. This flexibility enables the coils to be shaped and formed to fit various architectural designs, resulting in a seamless and aesthetically pleasing appearance. The ability to customize the coils also facilitates efficient installation, as they can be tailored to fit different dimensions, angles, and contours of roofs or facades. Additionally, aluminum is a non-combustible material, which makes it an excellent choice for roofs and facades in terms of fire safety. The non-combustible nature of aluminum coils greatly reduces the risk of fire spreading, providing an extra layer of protection to both the building and its occupants. In conclusion, aluminum coils significantly contribute to the durability of roofs and facades by offering corrosion resistance, lightweight yet high tensile strength, malleability for customization, and non-combustibility. These properties ensure that the roof or facade can withstand the test of time, harsh weather conditions, and external forces, making aluminum coils a reliable and long-lasting choice for any building structure.

- Q: I have a diamond back bike with an aluminum frame. will it rust if i ride or put it in the frame? is it bad for the bike?

- sophisticated task. search onto a search engine. this can help!

- Q: How are aluminum coils transported and delivered?

- Aluminum coils are typically transported and delivered through a combination of road, rail, and sea transportation methods. The specific mode of transportation will depend on various factors, including the distance between the manufacturing facility and the destination, the quantity of coils being transported, and the urgency of the delivery. For shorter distances, aluminum coils are commonly transported by road. Specialized trucks equipped with flatbed trailers or coil carriers are used to ensure safe and secure transportation. These trucks are designed with features like adjustable cradles or coil pads that prevent the coils from rolling or shifting during transit. When it comes to longer distances, rail transportation is often employed. Coils are loaded onto railcars, which can accommodate a significant number of coils depending on their size and weight. Rail transport offers the advantage of being more cost-effective and environmentally friendly compared to road transportation for long-haul journeys. In cases where aluminum coils need to be transported overseas or to another continent, sea transportation is the preferred option. Coils are carefully packed into shipping containers, ensuring they are adequately protected from potential damage during transit. These containers are then loaded onto cargo ships, which offer the necessary capacity and stability to transport large quantities of coils across long distances. Regardless of the mode of transportation, it is crucial to handle aluminum coils with care to prevent any damage or deformation. Special attention is given to protecting the coils from excessive vibration, impact, or exposure to adverse weather conditions. To ensure proper delivery, logistics companies often employ tracking systems that allow them to monitor the location and condition of the coils throughout the transportation process. Overall, the transportation and delivery of aluminum coils involve a well-coordinated logistics network to ensure the coils reach their destination in a timely and efficient manner while minimizing the risk of damage.

- Q: Can aluminum coils be used in the manufacturing of lighting fixtures?

- Yes, aluminum coils can be used in the manufacturing of lighting fixtures. Aluminum is a versatile and lightweight material that has excellent thermal conductivity properties, making it suitable for dissipating heat generated by the light source. Additionally, aluminum coils are easily moldable, allowing for the creation of intricate designs and shapes in lighting fixtures. The corrosion-resistant nature of aluminum also ensures the longevity and durability of the lighting fixture. Overall, aluminum coils are a popular choice in the manufacturing of lighting fixtures due to their numerous advantages.

- Q: This question asks for the method to determine the weight of a steel coil.

- <p>To calculate the weight of a steel coil, you need to know its length, width, and thickness, as well as the density of the steel material. The formula to calculate the weight is: Weight = (Length 脳 Width 脳 Thickness) 脳 Density. The density of steel is approximately 7850 kg/m鲁. Convert the dimensions to meters if they are not already in that unit. Multiply the volume (length 脳 width 脳 thickness) by the density to get the weight in kilograms. For example, if a coil is 2 meters long, 1 meter wide, and 0.005 meters thick, its weight would be (2 脳 1 脳 0.005) 脳 7850 = 78.5 kg.</p>

- Q: What are the different surface finishes for pre-painted aluminum coils?

- The different surface finishes for pre-painted aluminum coils include smooth, textured, embossed, brushed, and metallic finishes.

- Q: Is it possible to use an electric stove with an aluminum coil heater?

- <p>Yes, you can use an electric stove with an aluminum coil heater. However, it's important to ensure that the aluminum coil heater is designed for use with an electric stove. Aluminum is a good conductor of heat and can be used in heating elements. Make sure the heater is compatible with the stove's power requirements and that it's installed correctly to avoid any safety hazards. Always follow the manufacturer's instructions for installation and use.</p>

Send your message to us

Painted Aluminum Coil - 5052 Temper H24 0.8mm to 1mm Thick 1000mm Width Aluminum Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords