Polyisocyanurate Roofing Insulation Board with Aluminum Foil and LDPE Film for Bubble Foil Facing Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 90 cm²

- Supply Capability:

- 33412 cm²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum foil facing insulation for Roofing Insulation

1. Aluminum Foil Facing Description:

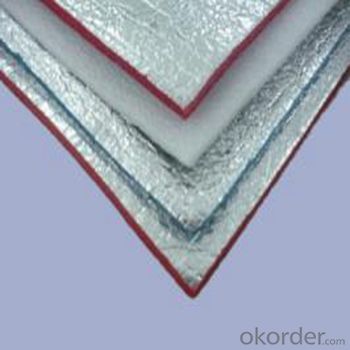

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

• The PSK aluminum foil facing, whose structure is white polypropylene/ fiberglass scrim/ kraft is mainly used for metal building insulation and suitable for the insulation of ware-house, factory, supermarket, office and so on.

• Double sided aluminum foil facing vapor barrier, whose structure is aluminum foil/ high strength kraft /fiberglass scrim /aluminum foil and laminated together by special flame retardant adhesive, can be used for roofing, wall insulation of house, warehouse, cold storages, factory and others.

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

• Smooth and clear surface;

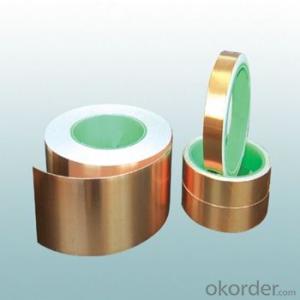

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

Basic weight | gsm | 120 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 140 75 | ASTM D828 |

Burst strength | N | 43 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C 66°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Basic weight | gsm | 120 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 140 75 | ASTM D828 |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

What is the storage condition?

1,The products should be stored at room temperature and kept from wet and heat source.

2, It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

3, The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: i mean, what do you use to make it stay put? glue? nails?

- Steel spreaders may be cheapest (as described in other answer) but many roofs have shingle nails sticking out,a couple dabs of caulking,glue,you're done! Be sure anything you use is compatible with your foam,some will just MELT it. Good Luck! DrJ

- Q: ... building code max. (R-50)???

- "R" I think stands for "Resistance" factor against heat loss. It resists the heat transfer but doesn't stop it. There is no such thing as perfect insulation. Snow itself is a rather good insulator. So even though you are only losing very little heat, the snow on top of the snow directly on the roof helps trap that heat at the bottom. So the first layer will melt.

- Q: I work with rubber roofing insulation. How , other than long sleeves, do I deal with the after effects of being exposed to this insulation.

- The talcum powder and clothing can only do so much. They can be effective, but can still lead to some itching once you are done working on the job. A cold (then warm) shower should be sufficient for clearing out the insulation and taking care of the itching.

- Q: what action should a plumber take?????

- struggling to understand your question! are you talking about a storage tank? what is the problem with the insulation? if it is in the way move it but insulation under a tank is not a problem the tank will need to be insulated any way!

- Q: roof was replaced eight years ago soon after there were leaks in the roof caused insulation toget wet then dry now the insulation is packed hard and has started to turn into power who would be responsible to replace the insulation.

- Sorry; I don't know of any roofer that would take responsabilty after eight years. Unless your insurance might be an option. Check with them and decide if your deductable is more than the repair if you would be better off doing it yourself. I would also be concerned about underlying materials, sheet rock, lumber, MOLD. You need someone to check thoroughly for mold being as it has been so long. GOod luck; Flip;

- Q: im thinking of putting rolled felt paper under my metal roofing would that work instead of the reflective insulation instead?

- rolled felt is not going to be as good as proper reflective insulation i dont think it would work

- Q: Can you put fiberglass insulation on the under side of roof tiles in the loft in the house?

- Not between tiles and roof sheathing, but YES on the inside of the sheathing, between the rafters. However, the recommended location is between the rafters on the FLOOR of the loft, unless you plan on using the loft as a living space.

- Q: What is the difference between roof and loft insulations?

- Potentially that the roof itself is insulated on the underside. A loft insulation could be that the base or floor of the loft/ attic is insulated. Otherwise, I'm not sure.

- Q: I would like to know which direction the one side with foil faces. The roof or the interior of the room?This is an attic room. Roof being "raw" i mean that it looks like cedar tongue in groove boards...then shingles on top of them. Which way do i face the foil side of the sheet..?thanx

- The foil side should go to the outside. I believe it's a moisture barrier.

- Q: Can I install rigid insulation between roof decking and shingles on a sloped roof?

- Lot of info missing to give you a good answer. Thickness of insulation. Slope of roof. But what it really comes down to is the building code in your area, contact local building inspector,

Send your message to us

Polyisocyanurate Roofing Insulation Board with Aluminum Foil and LDPE Film for Bubble Foil Facing Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 90 cm²

- Supply Capability:

- 33412 cm²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords