Reflective Roofing Insulation - Aluminum Foil with LDPE for Bubble Foil Facing Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 cm²

- Supply Capability:

- 33412 cm²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum foil facing insulation for Roofing Insulation

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• FSK aluminum foil facing is mainly used for duct wrap in HVAC system and other fields, such as vapor barrier etc., and suitable for off-line lamination of glass wool or rock wool. By special processing, the facing will have excellent flame retardant property.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

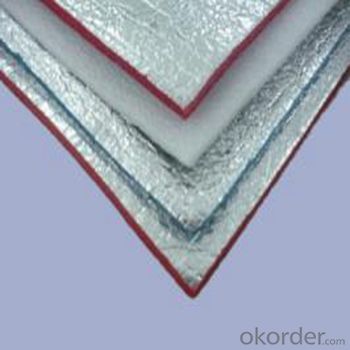

• The PSK aluminum foil facing, whose structure is white polypropylene/ fiberglass scrim/ kraft is mainly used for metal building insulation and suitable for the insulation of ware-house, factory, supermarket, office and so on.

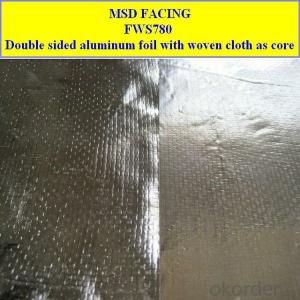

• Double sided aluminum foil facing vapor barrier, whose structure is aluminum foil/ high strength kraft /fiberglass scrim /aluminum foil and laminated together by special flame retardant adhesive, can be used for roofing, wall insulation of house, warehouse, cold storages, factory and others.

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

• Smooth and clear surface;

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

Basic weight | gsm | 120 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 140 75 | ASTM D828 |

Burst strength | N | 43 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C 66°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Basic weight | gsm | 120 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 140 75 | ASTM D828 |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

What is the storage condition?

1,The products should be stored at room temperature and kept from wet and heat source.

2, It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

3, The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Our roof tile is installed on top of galvanized iron sheets. We do not have any toher form of insulation. The roof tile or tegula is quite thick.

- . Insulation does a bunch of things; it hinders heat transfer and also Noise transfer. If the pitter-patter of rain doesn't bother you, you're ok. This tile is popular in California where the temperature is often mild. Of course people living in the Sierra Nevada Mts. wouldn't agree, but installation might NOT be necessary for you. Stick a 'remote thermometer' up there to monitor the temp. See the comfortHouse link below >>> .

- Q: How much insulation is required in a house roof in new York ?

- 323 square feet per cubic mile.

- Q: we replacing our torched down rubber roof and my contractor said we need to install a 1 inch rigid insulation..is the insulation needed?

- You would be foolish not to add the rigid foam under the new rubber roof. It gives you a new surface for an expensive roof. Definitely follow the contractors advice on this one.

- Q: I am really confused about this science stuff! Sustainability is terrible xP

- All versions of insulation are largely air that is kept from moving - air is a good insulator if convection - movement of heated or cooled air due to changes of density - is prevented. This assumes that a vapor barrier and caulking prevent actual air movement through the wall when a wind is blowing. Some insulators are also poor conductors of heat so the connection between inside and outside that might occur is broken. As it happens, glass used in fiberglass and minerals used in rock wool are actually pretty good conductors of heat in solid form but as fine particles and flakes they don't conduct well from one strand/piece to the next.

- Q: do i leave air gap in attic roof for insulation?

- The best way to set up an attic is to put a vapor barrier under the rafters (before nailing on the gyproc), then put the insulation (fibreglas batts) between the rafters to full depth (10 or 12 inches). Soffit vents are installed under the eaves at the sides of the roof, and gable vents are placed near the peak of the roof at the ends. This allows for airflow resulting from convection, particularly important in the summer months to remove heat buildup in the attic. If the insulation is adequate, it will not only isolate this heat buildup from the inside of the house in summer, but will prevent heat loss to the attic in winter. (The airflow in winter will be minimal, but will remove any moisture/condensation that might collect otherwise.)

- Q: The distance between knee wall and attic ceiling is about 6 foot. Could I push a perforated pipe between the rafters?

- That is an option. And there aren't many options.Not much is going to slide easily behind the insulation. I'm thinking --------------------. You are undoubtedly going to snag on roof nails coming through the decking. I don't know if they would hold up but the cardboard tubes wrapping paper comes on might work if you tape 2 together. and flatten and tape the end you will be pushing in first. cut slots with utility knife. I think your idea would work if you can afford the pipe. That's a tough one. When we convert attics we line those cavities with a styrofoam insulation chute end to end until we reach open ventilation-you probably know that by now. Give it a try.

- Q: Why would you not insulate between the rafters in an attic? I see a lot of houses with no insulation on the inside of the roof.

- Usually the floor of the attic is insulated unless you have cathedral ceilings. Then they have to insulate above the sloped ceiling and leave a little air space directly above the insulation that vents to perforated soffits and a ridge vent. You can also install foil faced plywood on the roof to improve energy performance.

- Q: hot because of all the added insulation. Is that what the insulation will do? Someone told me that it will save us on our cooling/heating bills, and that it will be warmer in the winter and cooler in the summer now. Is this true?

- Very humorous!!! you be attentive to final evening I had a dream that i became eating a significant marshmallow, as quickly as I awakened this morning my pillow became long previous! Ha Ha Ha the previous ones are the ultimate....

- Q: Best roofing insulation to keep warm in the winter?

- depending on where you live,if possible,r30 fiberglass or blown in either is the standard around here,and,for sure never block your ventilation,you need the air in your attic,freezing cold attics don't make you cold if you're properly insulated

- Q: Can I install rigid insulation between roof decking and shingles on a sloped roof?

- Lot of info missing to give you a good answer. Thickness of insulation. Slope of roof. But what it really comes down to is the building code in your area, contact local building inspector,

Send your message to us

Reflective Roofing Insulation - Aluminum Foil with LDPE for Bubble Foil Facing Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 cm²

- Supply Capability:

- 33412 cm²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords