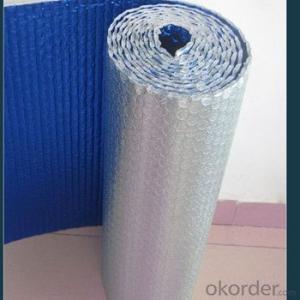

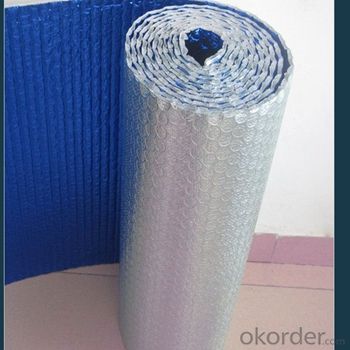

Aluminum Foil Facing PET + LDPE Bubble Foil Roofing Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 21 m.t

- Supply Capability:

- 566755 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

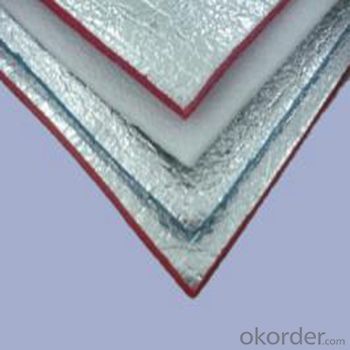

Aluminum foil facing insulation for Roofing Insulation

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

• Smooth and clear surface;

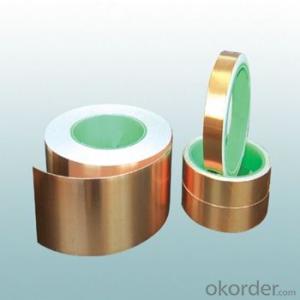

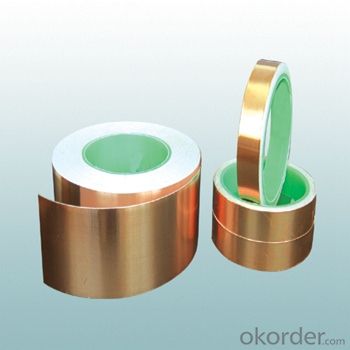

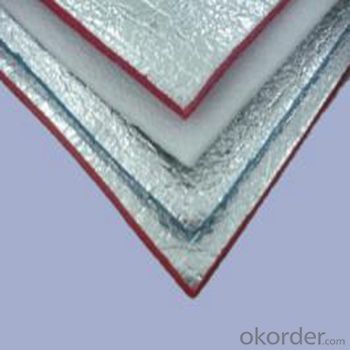

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

Basic weight | gsm | 120 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 140 75 | ASTM D828 |

Burst strength | N | 43 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C 66°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Basic weight | gsm | 120 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 140 75 | ASTM D828 |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

What is the storage condition?

1,The products should be stored at room temperature and kept from wet and heat source.

2, It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

3, The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: What is the preferred side of the lining material to face up in a baking tin: parchment paper or aluminum foil?

- <p>When lining a baking tin, it's generally better to use parchment paper with the non-shiny side facing up. Parchment paper is designed for direct contact with food and provides a non-stick surface, which is ideal for baking. Aluminum foil, on the other hand, should be dull side up to prevent food from sticking, but it's not recommended for direct contact with food as it can tear or create an uneven surface. If using foil, ensure it's food-safe and handle with care to avoid punctures.</p>

- Q: Is it possible to use aluminum foil with a reflective side for food freezing purposes?

- <p>Yes, aluminum foil facing can be used for freezing food. It helps to maintain the temperature and prevent freezer burn by acting as a barrier to air and moisture. However, it's important to ensure that the foil is food-grade and does not have any sharp edges that could puncture the food packaging. Additionally, it's recommended to wrap the food securely in the foil to minimize air exposure and maximize the preservation of the food's quality and taste.</p>

- Q: Is it possible to utilize a sheet of aluminum foil as a liner for a baking pan?

- <p>Yes, you can use a sheet of aluminum foil as a baking pan liner. It helps prevent food from sticking to the pan and makes cleanup easier. Ensure the foil covers the bottom and sides of the pan, and use enough to fold over the edges for easy removal of baked goods. However, avoid using foil for very high-temperature baking or broiling as it can melt or burn.</p>

- Q: What are the eco-friendly alternatives to traditional plastic food wraps?

- <p>Yes, there are several environmentally friendly alternatives to traditional plastic food wraps. These include beeswax wraps, which are reusable and made from natural materials like cotton, beeswax, and jojoba oil. Another option is silicone food wraps, which are durable, reusable, and can withstand high temperatures. Additionally, there are compostable wraps made from plant-based materials like cornstarch and cellulose, which break down naturally in compost. Using reusable containers or aluminum foil can also reduce the need for single-use wraps. These alternatives help reduce plastic waste and are more sustainable for the environment.</p>

- Q: What are the methods to stop the aluminum foil from curling at the edges while cooking?

- <p>To prevent the edges of aluminum foil from curling up during cooking, you can dampen the edges with a little water or cooking oil. This helps to weigh down the foil and keep it flat. Additionally, you can fold the edges inward to create a small rim, which can help contain the food and prevent the foil from lifting. Another method is to use a heavier object, such as a ceramic dish or a small pan, to press down on the foil, keeping it in place. Ensure that the object is heat-resistant and won't react with the foil. These techniques can help maintain the integrity of your foil and keep it from curling up during the cooking process.</p>

- Q: This question asks for the most effective method to smooth out wrinkles in aluminum foil facing material.

- <p>The best way to remove wrinkles from aluminum foil facing is to use a combination of heat and gentle stretching. First, preheat your iron on a low setting without steam. Place a thin cloth or parchment paper over the wrinkled aluminum foil facing to protect it from direct heat. Then, gently press the iron over the cloth, moving in a smooth, continuous motion. As the foil warms, it will become more pliable, allowing you to gently stretch and smooth out the wrinkles. Be cautious not to apply too much pressure or heat, as this can damage the foil.</p>

- Q: Is it possible to recycle aluminum foil facing multiple times? If yes, what is the process involved?

- <p>Yes, aluminum foil facing can be recycled multiple times. The recycling process involves collecting and sorting aluminum waste, which is then shredded or crushed. The material is melted in a furnace at high temperatures, and the molten aluminum is poured into molds to form new products. This process can be repeated indefinitely without losing the quality of the aluminum, making it one of the most recycled materials globally. The recycling of aluminum saves energy and reduces the environmental impact compared to producing aluminum from raw materials.</p>

- Q: Describe the most effective methods for utilizing aluminum foil in baking processes.

- <p>The best way to use aluminum foil in baking involves lining the baking sheet to prevent food from sticking and to simplify cleanup. Preheat the foil by placing it on the sheet and heating the oven before putting in the food. For even cooking, ensure the foil doesn't touch the heating elements. Use foil to wrap foods like potatoes or fish for steaming, or create packets for en papillote cooking. When using foil to cover food, tent it loosely to allow for air circulation. For browning, remove the foil during the last part of baking. Always handle with care to avoid tearing and ensure椋熷搧瀹夊叏.</p>

- Q: Is it safe to use old aluminum foil for food packaging, considering potential health risks and material degradation?

- <p>Using old aluminum foil for food packaging is not recommended. Over time, aluminum foil can become discolored, thin, or develop pinholes, which can compromise its integrity. These changes can lead to food contamination and the foil's ability to protect food from bacteria or other contaminants. Additionally, old aluminum foil may contain residues from previous uses that could mix with new food items, potentially causing off-flavors or health concerns. It's best to use fresh, clean aluminum foil for food packaging to ensure safety and hygiene.</p>

- Q: Explain the differences between aluminum foil facing and other types of food wrap.

- <p>Aluminum foil facing is a type of food wrap that is made from thin sheets of aluminum, which provides excellent barrier properties against air, moisture, and light. It is often used for cooking, baking, and preserving food. Unlike plastic wraps, it does not stick to food and can withstand high temperatures without melting. Other types of food wraps, such as plastic or cling wraps, are made from polymers and are not heat resistant. They are typically used for short-term food storage and are not suitable for cooking. Paper-based wraps, like parchment or wax paper, are used for baking and providing a non-stick surface but do not offer the same barrier properties as aluminum foil.</p>

Send your message to us

Aluminum Foil Facing PET + LDPE Bubble Foil Roofing Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 21 m.t

- Supply Capability:

- 566755 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords