Aluminum Foil Sheets Kroger AA3003 Aluminium Trailers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminium Sheets AA3003 for Making Aluminium Trailers

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Aluminium Sheets AA3003 for Making Aluminium Trailers

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminium Sheets AA3003 for Making Aluminium Trailers

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

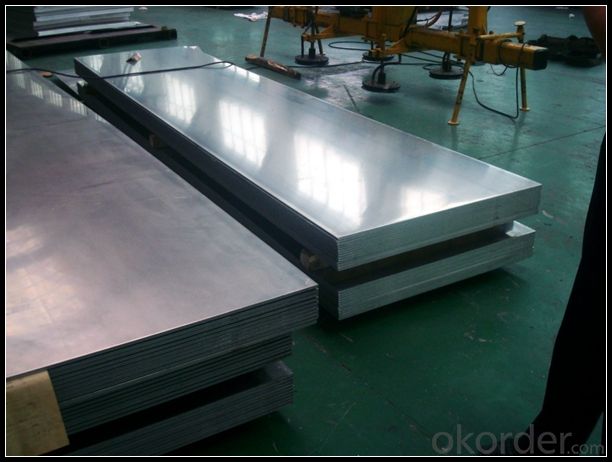

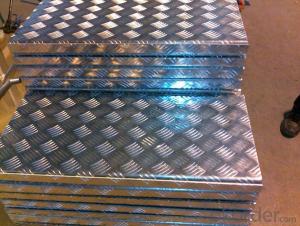

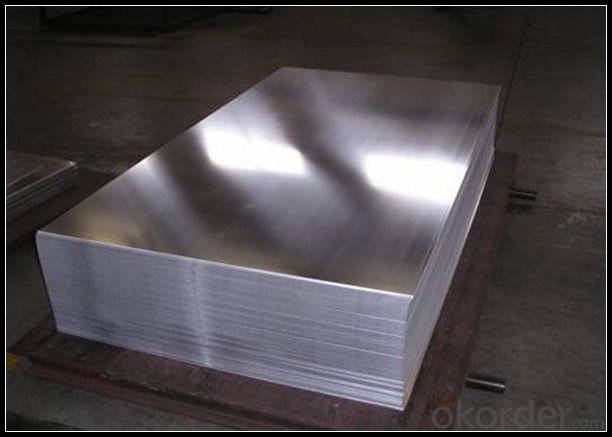

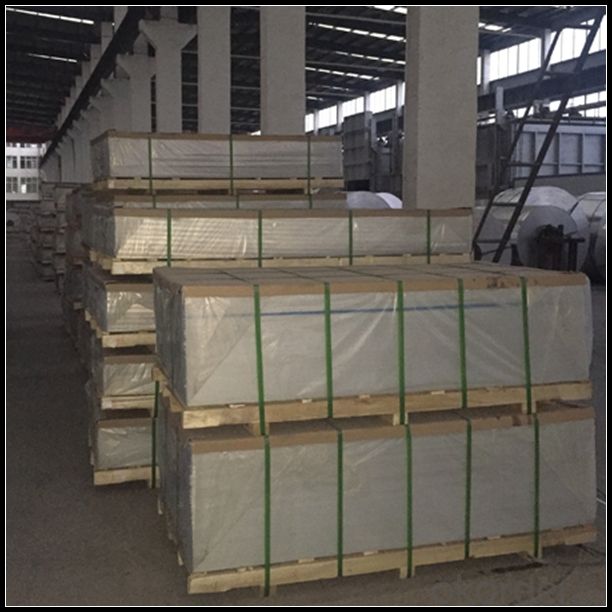

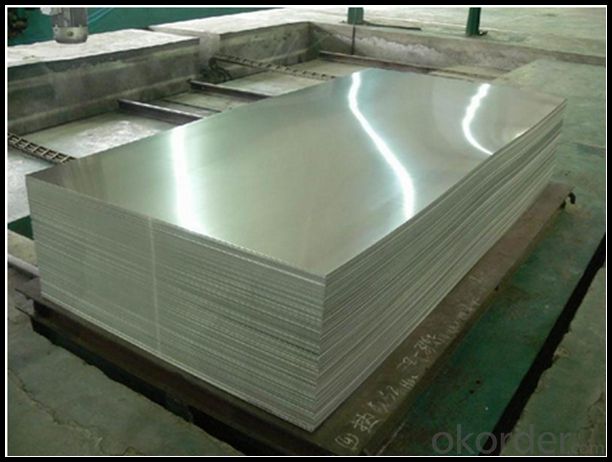

5. Image of Aluminium Sheets AA3003 for Making Aluminium Trailers

6. Package and shipping of Aluminium Sheets AA3003 for Making Aluminium Trailers

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: ive been working with parts for a robot without gloves and ive manged to 3 cuts in my fingers, also my hands get covered with powdered aluminum from sanding the peices, can this be dangerous to my health?

- Aluminum it's self is not dangerous. But as for as cuts, Any cut can become infected from germs from any source.

- Q: Are aluminum sheets resistant to chemicals?

- Yes, aluminum sheets are generally resistant to a wide range of chemicals.

- Q: What are the common thicknesses available for aluminum sheets?

- The common thicknesses available for aluminum sheets range from 0.006 inches to 0.25 inches, with standard options including 0.016, 0.020, 0.025, 0.032, 0.040, 0.050, and 0.063 inches.

- Q: Which are better? I currently have steel (kinda ugly) rims on my Chevy Blazer right now, and my roommate has some aluminum alloy rims that will fit that he wants to sell me. He hates my steel rims so much that he's willing to sell me the alloy ones for $100.Should I take it? Or just stick with my steel ones?

- Steel Vs Alloy Wheels

- Q: Are aluminum sheets suitable for food processing conveyor systems?

- Aluminum sheets are a great choice for food processing conveyor systems as they offer several advantages. Firstly, they are lightweight yet strong, making them perfect for conveyor systems that require frequent movement and transportation of food products. Their lightweight nature allows for easy installation, maintenance, and modification of conveyor systems, while their strength ensures the equipment's durability and longevity. Secondly, aluminum is corrosion-resistant, which is crucial in food processing environments where exposure to moisture, chemicals, and food acids is common. This resistance to corrosion ensures that the conveyor system remains hygienic and free from contamination, meeting the industry's strict food safety standards. Furthermore, aluminum is non-toxic, making it a safe material for food handling and contact. It does not react with food or release any harmful substances, ensuring the integrity and safety of the food being processed on the conveyor system. Moreover, aluminum is easy to clean and maintain, which is essential in food processing environments where hygiene is of utmost importance. The smooth and non-porous surface of aluminum sheets allows for easy removal of food particles, grease, and other contaminants, reducing the risk of bacterial growth and cross-contamination. In conclusion, aluminum sheets are highly suitable for food processing conveyor systems due to their lightweight, corrosion-resistant, non-toxic, and easy-to-clean properties. They provide a reliable and efficient means of transporting food products while ensuring the highest standards of hygiene and food safety.

- Q: Can aluminum sheets be perforated for decorative or functional purposes?

- Yes, aluminum sheets can be perforated for both decorative and functional purposes. Perforating aluminum sheets allows for the creation of intricate patterns or designs and also enhances the sheet's functionality by improving ventilation, reducing weight, or enhancing acoustic properties.

- Q: Im wondering what type of clutch would be better for my fox body mustang. A aluminum or steal. And why

- aluminum if you are drag racing ( have to learn to feather the clutch a bit) STEEL on the street( easier to keep the fire lit for mere mortals ) course you can use aluminum on the street--most people cant, because you have to be easy with the clutch-but it gives you an excuse why people cant borrow your car

- Q: What is the electrical resistivity of 101 aluminum sheets?

- The electrical resistivity of 101 aluminum sheets can vary depending on the specific grade and condition of the aluminum. However, on average, aluminum has an electrical resistivity of about 2.65 x 10^-8 ohm-meters. It is important to note that this value may slightly vary due to impurities or other factors.

- Q: Are aluminum sheets suitable for use in marine or saltwater environments?

- Yes, aluminum sheets are suitable for use in marine or saltwater environments. Aluminum has excellent corrosion resistance properties and is known for its ability to withstand the harsh conditions found in marine environments. Unlike many other metals, aluminum forms a protective oxide layer on its surface when exposed to oxygen, which helps prevent further corrosion. This oxide layer acts as a barrier, protecting the underlying metal from saltwater and other corrosive elements. Additionally, aluminum is lightweight yet strong, making it an ideal choice for marine applications where weight reduction is important. It is commonly used in the construction of boats, ships, offshore structures, and other marine equipment.

- Q: My new home has a mix of copper and aluminum wiring. My mother used a shop vac in one of the recepticles last week and blew two of them in my bedroom. Then this weekend my brother was replacing my exhaust fan in the bathroom and that proceeded to blow the entire bedroom and bathroom including ceiling fans, lights and all recepticles. Does anyone have any ideas?

- You said new home. Aluminum hasn't been used in house wiring for many years. It is now only used for the main service wires coming in to the panel. Shop vacs can trip 15 amp bedroom circuits. I think you need to call in an electrician if your dad reset all the breakers. Have him do the exhaust fan too. Let your brother help mom with the cleaning. Forget about doing your own wiring or replacing things yourself. Hire an electrician. The firefighters will thank you.

Send your message to us

Aluminum Foil Sheets Kroger AA3003 Aluminium Trailers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords