Aluminum Foil Sheets - Direct Rolling Aluminium Coils for Hot Casting Ships

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

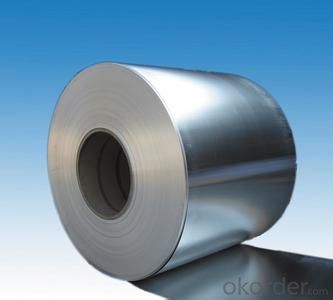

1.Structure of Direct Rolling Aluminium Coils for Hot Casting Ships

Direct Rolling Aluminium Coils for Hot Casting Ships is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Direct Rolling Aluminium Coils for Hot Casting Ships

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image of Direct Rolling Aluminium Coils for Hot Casting Ships

4. Product Specification of Direct Rolling Aluminum Coils for Second Casting

| Rolling | Temper | Thickness | Width | Weight |

| Direct Rolling | F | 3MM-8MM | 1200MM-1800MM | 3-6 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Can aluminum sheets be used for protective enclosures?

- Aluminum sheets have the ability to be utilized for protective enclosures. This material, known for its versatility and lightweight nature, offers exceptional durability and resistance to corrosion. It can easily be transformed into various shapes and sizes, making it suitable for constructing protective enclosures across a wide range of applications. Industries such as electronics, telecommunications, aerospace, and automotive commonly employ aluminum enclosures, which safeguard against environmental factors like moisture, dust, and electromagnetic interference. Moreover, these enclosures can be further improved with the addition of coatings or insulation materials to meet specific requirements for thermal insulation, fire resistance, or electrical conductivity. All in all, aluminum sheets are a dependable option for protective enclosures due to their strength, adaptability, and capacity to endure challenging conditions.

- Q: Can aluminum sheets be polished?

- Certainly, aluminum sheets are capable of being polished. Aluminum, being a relatively malleable metal, lends itself to easier polishing in comparison to harder metals like stainless steel. The act of polishing aluminum sheets entails the utilization of abrasive substances such as sandpaper or polishing compounds. This serves to eliminate any blemishes, scratches, or oxidation present on the surface. Typically, the process involves multiple stages of polishing, employing varying degrees of grit in sandpaper or polishing compounds. Step by step, a smoother and more reflective surface is attained. Polished aluminum sheets find common usage in various applications, including automotive components, architectural elements, and ornamental objects. The polishing process elevates the metal's aesthetic appeal, imparting a glossy and reflective finish.

- Q: Can aluminum sheets be embossed or engraved?

- Aluminum sheets have the capability to be embossed or engraved. The act of embossing entails the formation of a raised design or pattern on the aluminum sheet's surface, whereas engraving involves the cutting or etching of a design into the surface. These techniques are applicable for incorporating decorative or functional elements into aluminum sheets. In numerous industries, such as automotive, aerospace, signage, and architectural applications, embossed or engraved aluminum sheets are commonly employed. The process of embossing or engraving aluminum sheets typically necessitates the utilization of specialized machinery or tools to achieve the desired design.

- Q: Can aluminum sheet be used for automotive body panels?

- Yes, aluminum sheet can be used for automotive body panels. In fact, aluminum is becoming increasingly popular in the automotive industry for its numerous advantages. Firstly, aluminum is lighter than steel, which helps to improve fuel efficiency and overall vehicle performance. Additionally, aluminum is highly corrosion-resistant, making it a durable choice for automotive body panels that are exposed to the elements. Aluminum also has excellent formability and can be easily shaped into complex designs, allowing for greater design flexibility in vehicle manufacturing. Furthermore, aluminum offers superior crash absorption capabilities, enhancing the safety of vehicles. However, it's important to note that while aluminum is a viable option for automotive body panels, it may require specialized equipment and techniques for welding and repair.

- Q: I know that aluminum doesn't belong in the human body. As a canister to hold liquids which will be consumed later, is aluminum good or bad to use?

- In my opinion.... Typical plastic bottles with bpa are the worst for you. Aluminum bottles are a step up and great for the environment since aluminum does not require pollutive materials to make and the material itself is not hazardous to the environment like plastic is. Hard plastic bottles without bpa and other harmful materials/chemicals is better for your health as long as it is not exposed to the sun or heat. Stainless steal containers are great to use, but what can be even better?. Water containers that are made out of animals. Example: animal skin, goat bladder. Animal bladders do a great job holding in animal urine, why not use them to hold drinkable water?? You also do not have to worry about any harmful product getting inside your body since animals are 100% biodegradable and they are natural to the environment. When I deploy to Iraq, im going to find a goat and rip out its bladder! Then im going to convert it into a water container for my camelbak!

- Q: the aluminium pull tabs are in a jucy juice bottle

- 82% okorder /

- Q: What are the different methods of surface protection for outdoor aluminum sheet?

- There are several methods of surface protection for outdoor aluminum sheets. One common method is painting the surface with a protective coating, such as a weather-resistant paint or powder coating. Another method is anodizing, which involves creating a durable oxide layer on the surface of the aluminum. Additionally, applying a clear protective film or using a protective sealant can also help protect the aluminum sheet from outdoor elements.

- Q: How do aluminum sheets compare to steel sheets in terms of weight?

- Aluminum sheets, when compared to steel sheets, are significantly lighter in weight. This is because aluminum has a lower density than steel, making it a more lightweight and versatile material. The specific weight difference between aluminum and steel sheets will depend on the thickness and dimensions of the sheets. However, generally speaking, aluminum sheets can weigh about 1/3 less than steel sheets of the same size. This makes aluminum sheets an ideal choice in applications where weight is a critical factor, such as in the aerospace industry or for lightweight structures.

- Q: The furnace above is only hot enough to melt lead, but isn't hot enough to melt aluminum. I'm not looking for a blowtorch, or something too expensive or could melt gold, but just something that i can buy and is like the one above but isn't that expensive and can melt aluminum. Thanks!

- Aluminum melts below 1300F These gold and silver melters like the one in the link go to 2000F or more and should work for aluminum. I guess more small melters of metals want to melt gold and silver than aluminum.

- Q: Are aluminum sheets suitable for lightweight structures?

- Yes, aluminum sheets are suitable for lightweight structures due to their low density and high strength-to-weight ratio.

Send your message to us

Aluminum Foil Sheets - Direct Rolling Aluminium Coils for Hot Casting Ships

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords