Aluminum Foil Facing Insulation Foil Mylar for Cable Production and Bubble Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 lb/ft

- Supply Capability:

- 5000000 lb/ft/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

• Smooth and clear surface;

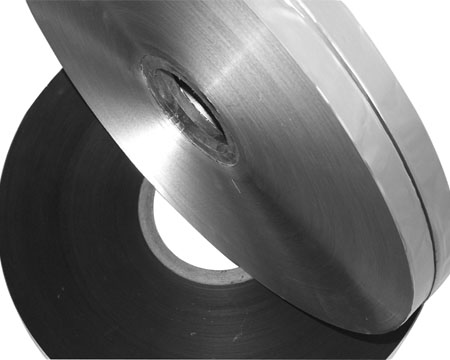

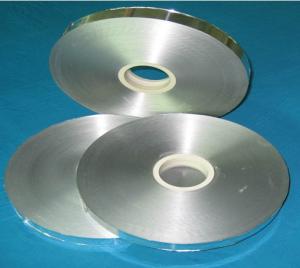

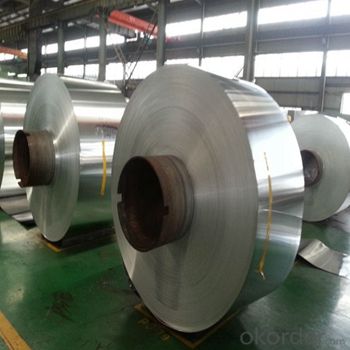

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

Name:AL+LDPE | |||

Structure | Thickness(mic) | Weight(g/m2) | Yield(m2/kg) |

AL7+ LDPE12 | 21mic | 36 | |

AL7+ LDPE15 | 24 mic | 39 | |

AL9+ LDPE12 | 23mic | 43 | 23 |

AL9 +LDPE15 | 26mic | 48 | 21 |

AL9 +LDPE19 | 30mic | 54 | 19 |

AL9 +LDPE23 | 34mic | 60 | 17 |

AL12 +LDPE12 | 26mic | 52 | 19 |

AL12 +LDPE15 | 29mic | 56 | 18 |

AL12 +LDPE19 | 33mic | 62 | 16 |

AL12 +LDPE23 | 37mic | 67 | 15 |

AL12 +LDPE36 | 50mic | 87 | 12 |

AL15 +LDPE19 | 36mic | 70 | 14 |

AL25 +LDPE12 | 39mic | 87 | 12 |

AL25 +LDPE23 | 50mic | 102 | 10 |

AL40 +LDPE12 | 54mic | 127 | 8 |

AL40 +LDPE15 | 57mic | 131 | 8 |

AL40 +LDPE23 | 65mic | 143 | 7 |

AL40 +LDPE36 | 78mic | 161 | 6 |

AL50 +LDPE12 | 64mic | 154 | 6 |

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 80 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 95 50 | ASTM C1136 |

Burst strength | N | 25 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Water Soak Test | 24hrs | No delamination | ---------- |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

(3) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(4) How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served

- Q: What are the methods to avoid aluminum leaching from aluminum foil into food during cooking or storage?

- <p>To prevent aluminum from leaching into food when using aluminum foil facing, avoid direct contact between the foil and acidic or salty foods, as these can cause the aluminum to leach. Do not use aluminum foil at high temperatures, as it can degrade and release aluminum particles. Opt for aluminum-free alternatives like parchment paper or silicone baking mats for lining pans or wrapping foods. When using aluminum foil, ensure it's the heavy-duty type, which is less likely to break down and release aluminum. Always wash hands and utensils that have come into contact with aluminum foil to minimize ingestion of any residual aluminum.</p>

- Q: Is it possible for metal shavings to contaminate food when using aluminum foil with a shiny side?

- <p>There is minimal risk of metal shavings getting into food when using aluminum foil facing. Aluminum foil is designed to be safe for food contact and is generally resistant to shedding particles. However, if the foil is damaged or handled roughly, small particles could potentially come off. To mitigate this risk, ensure the foil is in good condition, avoid tearing it, and handle it carefully to prevent any metal contamination.</p>

- Q: Is it safe to use aluminum foil facing to wrap food for transportation purposes?

- <p>Yes, you can use aluminum foil facing to wrap food for transporting. Aluminum foil is a common and safe material used for food packaging due to its ability to protect food from air, moisture, and bacteria. It also helps to maintain the temperature of the food, keeping it hot or cold as needed. However, ensure that the aluminum foil is food-grade and clean to prevent any contamination. Avoid using it in direct contact with acidic or salty foods as it may react and leach aluminum into the food, which is not recommended for consumption.</p>

- Q: Is it possible to enhance the flavor of food by using aluminum foil facing?

- <p>Yes, using aluminum foil facing can help make food more flavorful. It can seal in moisture and steam, which helps to keep the food juicy and tender. The foil also allows for even heat distribution, which can enhance the cooking process and the development of flavors. However, it's important to note that aluminum foil should not be used with acidic foods as it can react and potentially leach into the food. Additionally, for certain dishes, direct contact with the heat source can be necessary for achieving a desired texture or flavor, so the use of foil should be considered based on the specific recipe and cooking method.</p>

- Q: This question asks for a comparison of the pros and cons of using aluminum foil as a facing material in food packaging.

- <p>Aluminum foil facing in food packaging offers several advantages, such as excellent barrier properties against light, oxygen, and moisture, which helps in preserving the freshness and taste of food. It is also lightweight, cost-effective, and provides a shiny, visually appealing appearance. Additionally, aluminum foil is recyclable, contributing to sustainability efforts. However, there are disadvantages, including its limited heat resistance, which can lead to warping or melting when exposed to high temperatures. It can also cause environmental concerns due to improper disposal, as it is not biodegradable and can contribute to littering if not recycled properly.</p>

- Q: Is it safe to use aluminum foil with a shiny side to wrap food for grilling?

- <p>Yes, you can use aluminum foil facing to wrap food for grilling. The shiny side of aluminum foil is non-stick and is safe for use with food. It helps prevent food from sticking to the foil and allows for even cooking. However, ensure that the foil does not come into direct contact with the heat source as it may cause the foil to tear or burn, potentially releasing aluminum particles into the food. Always follow grilling guidelines and safety precautions to avoid any risks.</p>

- Q: This question asks about the various types of aluminum foil facing used in construction and insulation materials.

- <p>Aluminum foil facing is used in various applications, including insulation and construction materials. The different types include: 1) Plain Foil Facing, which is a smooth, uncoated aluminum foil; 2) Coated Foil Facing, which has a protective coating applied to one or both sides; 3) Laminated Foil Facing, where aluminum foil is bonded to other materials like polyester or polyethylene; 4) Embossed Foil Facing, featuring a pattern or texture on the surface for added strength or aesthetic purposes; and 5) Reinforced Foil Facing, which incorporates additional materials to enhance durability and tear resistance.</p>

- Q: What are the optimal practices for storing food using aluminum foil, considering the direction of the foil's facing?

- <p>The best way to store food in aluminum foil is to ensure that the dull side faces the food and the shiny side is on the outside. This is because the dull side is more heat resistant and less likely to contaminate the food with any potential chemicals from the foil. When wrapping food, seal the edges tightly to keep air and moisture out, which helps in preserving the freshness and quality of the food. Always use aluminum foil as a single-use item to avoid any potential transfer of bacteria or contaminants from previous uses.</p>

- Q: Is it safe and effective to use aluminum foil with a shiny side facing up to line a baking pan for baking purposes?

- <p>Yes, you can use aluminum foil facing to line a baking pan for baking. The shiny side of the foil, which is the aluminum side, is safe for direct contact with food and can be used to line pans for baking. It helps prevent food from sticking and makes cleanup easier. However, ensure the foil is heavy-duty to withstand high temperatures and does not tear easily. Always follow the manufacturer's guidelines for safe use and avoid overheating, as aluminum foil can melt at very high temperatures.</p>

- Q: This question asks for a comparison of various materials used for food wrapping, highlighting their unique properties and uses.

- <p>Different types of food wrap materials include plastic wrap, aluminum foil, parchment paper, and beeswax wraps. Plastic wrap is versatile, clingy, and great for sealing in freshness, but it's not microwave-safe and may not be eco-friendly. Aluminum foil is heat-resistant, ideal for cooking and sealing, but it's not reusable and can tear easily. Parchment paper is non-stick, reusable, and safe for baking, but it's not as airtight as plastic. Beeswax wraps are eco-friendly, reusable, and can be used in the oven, but they are more expensive and not as widely available. Each type has its advantages and disadvantages depending on the specific use case, such as food storage, cooking, or sustainability.</p>

Send your message to us

Aluminum Foil Facing Insulation Foil Mylar for Cable Production and Bubble Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 lb/ft

- Supply Capability:

- 5000000 lb/ft/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords