Aluminum Foil Facing Uninsulated Insulated Flexible Duct Factory

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Aluminium Flexible Duct

Flexible Duct is widely used in Heating, Ventilation and Air Conditioning (HVAC) systems for air ventilation applications.

Features and Characters of Aluminium Flexible Duct:

-Applied in Heating, Ventilation and Air Conditioning

-Non-insulated and insulated Flexible Duct offered

-Up to 150℃ and 250℃ high temperature

-Fire Retardant

Specification of Aluminium Flexible Duct:

Non-insulated Flexible Duct

Insulated Flexible Duct

Combined Flexible Duct

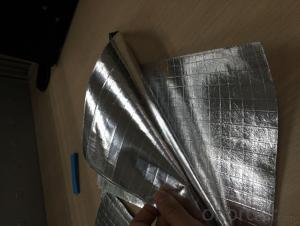

Pictures of Aluminium Flexible Duct:

FAQ of Aluminium Flexible Duct:

1. What temperature maximum? Our products: 150℃ and 250℃

2. What MOQ? Our MOQ: 500 pcs

3. What payment terms? We accept T/T and L/C

4. Lead time: 10 days

- Q: What are the potential health advantages of utilizing recycled aluminum items for cooking or baking purposes?

- <p>Using recycled aluminum products for cooking or baking can have some health benefits. Recycled aluminum is generally considered safe as it undergoes a thorough purification process to remove any contaminants. It is also more environmentally friendly, reducing the need for mining new aluminum, which can have negative health impacts due to the chemicals used in the extraction process. Additionally, recycled aluminum products can be more cost-effective, making them accessible to a wider range of consumers. However, it's important to ensure that the recycled aluminum products are from reputable sources and meet safety standards to avoid any potential health risks.</p>

- Q: Can aluminum foil be utilized as a substitute for a frying pan to cook fried rice or stir fry dishes?

- <p>Using aluminum foil to make fried rice or stir fry dishes is not recommended. Aluminum foil is not designed for direct contact with high heat and can melt, leading to uneven cooking and potentially releasing harmful substances into the food. Instead, use a proper non-stick pan or wok designed for high-heat cooking to ensure even heating and prevent food from sticking, which is essential for quick and easy stir frying.</p>

- Q: Is it possible to use aluminum foil facing as a material for creating a potpourri sachet?

- <p>Yes, you can use aluminum foil facing to make a potpourri sachet. Aluminum foil is a versatile material that can be cut into small squares or shapes and filled with dried flowers, herbs, and spices to create a fragrant sachet. Ensure the foil is clean and free from any oils or residues before use. Seal the edges of the foil to prevent the contents from spilling out. While it's not as breathable as fabric, it can still hold the scent and keep the potpourri fresh.</p>

- Q: What are the methods to prevent food from sticking to the aluminum foil surface during cooking?

- <p>To prevent food from sticking to the surface of aluminum foil when cooking, you can use a few techniques. First, lightly coat the foil with a thin layer of oil or non-stick cooking spray. This creates a barrier that food won't stick to. Second, ensure that the foil is smooth and wrinkle-free; any rough spots can cause food to stick. Additionally, avoid overfilling the foil as this can lead to uneven cooking and sticking. Finally, consider using parchment paper or a silicone baking mat instead of foil for some foods, as they can provide a non-stick surface without the risk of aluminum foil tearing or food sticking.</p>

- Q: Is it safe and effective to use aluminum foil with a reflective side to wrap vegetables when grilling?

- <p>Yes, you can use aluminum foil facing to wrap vegetables for grilling. Aluminum foil helps to retain moisture and heat, ensuring that the vegetables cook evenly and remain tender. The reflective side of the foil can also help to distribute heat more evenly. However, be cautious not to let the foil touch the flame directly, as it can cause flare-ups. Make sure to poke some holes in the foil to allow steam to escape and prevent the vegetables from becoming too soggy.</p>

- Q: This question asks about the various types of aluminum foil facing that can be found in the market.

- <p>Aluminum foil facing is commonly used in construction for insulation and moisture protection. The different types available on the market include: 1) Plain Foil Facing, which is a simple, smooth aluminum surface; 2) Embossed Foil Facing, featuring a textured pattern for added strength; 3) Reinforced Foil Facing, which incorporates additional materials for enhanced durability; 4) Coated Foil Facing, where the aluminum is coated with other substances to improve performance; and 5) Laminated Foil Facing, which combines aluminum with other materials for specific applications. Each type serves different purposes and has unique properties that cater to various construction and industrial needs.</p>

- Q: Is it safe and effective to use aluminum foil with a reflective side to wrap vegetables for grilling or roasting?

- <p>Yes, you can use aluminum foil facing to wrap vegetables before grilling or roasting. Aluminum foil is a common and versatile tool in cooking, especially for grilling and roasting. The reflective side of the foil can help in evenly distributing heat and retaining moisture, which is beneficial for cooking vegetables. It prevents them from drying out and allows them to cook evenly. However, ensure the foil does not come into direct contact with the heat source as it may cause the foil to tear or the vegetables to burn. Always monitor the cooking process to prevent any potential issues.</p>

- Q: How to properly handle aluminum foil when it is exposed to hot or cold temperatures.

- <p>When handling aluminum foil that is hot or cold, it's best to use tongs, a fork, or a pair of gloves to avoid direct skin contact. This prevents burns from hot foil or frostbite from cold foil. If the foil is being used in cooking, ensure it's not in direct contact with the heat source for prolonged periods to prevent melting. For cold applications, like insulation, make sure the foil is dry to maintain its effectiveness as a barrier. Always handle with care to prevent tearing or puncturing the foil, which could compromise its integrity.</p>

- Q: What are the potential hazards or dangers of using aluminum foil facing in construction or other applications?

- <p>Using aluminum foil facing can pose certain risks, particularly in construction. It may not provide adequate insulation, leading to energy inefficiency. Additionally, it can trap moisture, causing mold or mildew growth and potential structural damage. Aluminum foil facing can also be a fire hazard if it's not properly installed or if it comes into contact with electrical wiring. Moreover, it may not be as durable as other materials, leading to a shorter lifespan and the need for more frequent replacements. It's crucial to consider these factors and consult with professionals when deciding to use aluminum foil facing in any application.</p>

- Q: Explain the differences between thin and thick aluminum foil facing in terms of thickness, durability, and usage.

- <p>Thin aluminum foil facing is characterized by its low thickness, which makes it flexible and easy to handle but less durable. It's commonly used for wrapping food, baking, and protecting surfaces. Thick aluminum foil facing, on the other hand, is more robust and tear-resistant, suitable for heavy-duty applications such as construction, insulation, and packaging. The thicker material offers better protection and durability, but it's less pliable and can be more challenging to work with.</p>

Send your message to us

Aluminum Foil Facing Uninsulated Insulated Flexible Duct Factory

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords