Nitrile Rubber Foam Insulation Sheet with Aluminum Foil Facing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Flexible Rubber Plastic Insulation Material Description

rubber plastic is a high quality heat-insulating and heat-preservation material which use butyronitrile rubber and polyvinychloride(NBR,PVC) as main raw materials.

The productionprocess includes mixing, tensing and continuous extruding , heating andfoaming, cooling and cutting.

2.Main Features of Rubber Plastic

-Lower heat-conductivity

-Higher fire-blockingperformance

-Damp-proof andWater-proof

-Softness

-Neat and

-Easy to installeasy handing and storage

-Good flexibilityand tenacity

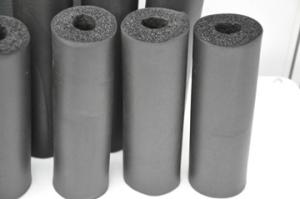

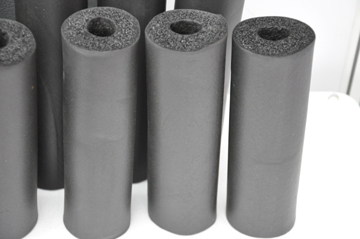

3.Rubber Plastic Images

4.Rubber Plastic Specification

--Rubber Plastic Sheet

Density(kg/m3) | 40-90 | ||||

Thickness(mm) | 10 mm | 15 mm | 20 mm | 25 mm | 30 mm |

Length (m) | 20 | 20 | 10 | 10 | 10 |

Width (m) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of HVAC materials,is one of the large-scale professional investment building materials production bases in China.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Is it possible to use aluminum foil facing material to create a bag for storing food items, specifically sandwiches?

- <p>While it is technically possible to use aluminum foil facing to create a makeshift sandwich bag, it is not recommended for long-term food storage. Aluminum foil is not airtight and does not provide a barrier to bacteria or moisture, which can lead to spoilage. For proper food storage, it's better to use food-safe plastic bags or containers designed for this purpose, which offer better protection against contamination and help maintain freshness.</p>

- Q: What safety measures should be considered when using aluminum foil in a kitchen setting?

- <p>When using aluminum foil in the kitchen, it's important to handle it carefully to avoid cuts from sharp edges. Always use a cutting board when cutting foil to prevent damage to countertops. Avoid using aluminum foil with non-stick cookware, as it can scratch the surface. Do not use aluminum foil in broilers or ovens above 450掳F (232掳C), as it can melt and release toxic fumes. Never use aluminum foil to wrap foods that will be cooked in a microwave, as it can cause sparks and fires. Always ensure that foil is properly secured when used to cover food to prevent it from coming into contact with the heating elements of the oven.</p>

- Q: Is it possible to use aluminum foil sheets as a substitute for traditional spring roll wrappers?

- <p>No, you cannot use aluminum foil sheets to make a spring roll. Spring rolls require a thin, flexible, and edible wrapper, typically made from rice flour or wheat flour. Aluminum foil is a non-edible, rigid material that would not only be inedible but also would not hold the filling properly. Instead, use proper spring roll wrappers or consider alternatives like lettuce leaves for a low-carb option.</p>

- Q: Is it possible to use aluminum foil with a facing layer to create a sandwich?

- <p>Using aluminum foil facing to make a sandwich is not recommended. Aluminum foil is not designed for direct food contact, especially when heated, as it can leach aluminum into the food, which is potentially harmful. Instead, use materials specifically designed for food contact, such as wax paper, parchment paper, or plastic wrap, which are safe for contact with food and can withstand the temperatures involved in making a sandwich.</p>

- Q: What are the advantages of using aluminum foil as a reflective surface in various applications, particularly in health contexts?

- <p>Using aluminum foil facing provides several health benefits, particularly in cooking and food preservation. It helps retain moisture in foods, reducing the need for added fats and oils, which can contribute to a healthier diet. Reflective aluminum foil can also help distribute heat evenly in ovens, ensuring food cooks more uniformly and reduces the risk of overcooking or burning. Additionally, it can help in food reheating, ensuring that food is heated evenly and thoroughly, which is important for food safety. In some cases, aluminum foil can also be used to create a barrier against harmful UV rays in tanning beds, although this is not recommended due to potential health risks associated with tanning. Overall, the use of aluminum foil facing can contribute to healthier cooking practices and food safety.</p>

- Q: Is it possible to use aluminum foil facing as a substitute for a roasting pan?

- <p>While aluminum foil facing can be used in some baking situations, it is not recommended to use it as a direct substitute for a roasting pan. Aluminum foil is not designed to withstand the high temperatures of a roasting process and can melt or warp, leading to uneven cooking and potential safety hazards. A proper roasting pan is made to handle high heat and distribute it evenly, ensuring that your food cooks properly. For best results and safety, use a designated roasting pan or a baking sheet with a higher heat tolerance.</p>

- Q: Explain the various applications of aluminum foil facing in different contexts.

- <p>Aluminum foil facing can be used in various ways depending on the application. In construction, it serves as a vapor barrier to prevent moisture from affecting the insulation. In packaging, it's used for food preservation, providing a barrier against air and light, which helps to keep food fresh. In the automotive industry, it's used for heat reflection and insulation in car engines. It's also used in the manufacturing of reflective materials and in art for creating unique textures and effects. Additionally, aluminum foil facing is utilized in the aerospace industry for heat shielding and in the medical field for sterilization purposes. Each application leverages the properties of aluminum foil, such as its light weight, durability, and heat resistance.</p>

- Q: This question asks for methods to clean stubborn food residue from the aluminum foil facing of a baking sheet or similar kitchen item.

- <p>To remove stuck-on food from aluminum foil facing, first let the surface cool down. Then, use a plastic scraper or an old credit card to gently lift the residue without scratching the foil. For stubborn stains, make a paste of baking soda and water, apply it to the area, and let it sit for a few minutes before scrubbing. Alternatively, use a mixture of vinegar and water to loosen the food particles. After cleaning, rinse thoroughly and dry to prevent further food adhesion.</p>

- Q: Is it possible to use aluminum foil with a reflective side facing up for cooking or frying food?

- <p>Using aluminum foil with a reflective side facing up for frying food is not recommended. Aluminum foil is not designed for direct contact with high heat sources like frying pans or oil. It can cause uneven heating, stick to the food, and potentially release harmful aluminum particles into the food. For safe and effective cooking, use appropriate cookware designed for high heat and direct contact with food.</p>

- Q: Can aluminum foil be shaped into a fish basket?

- <p>Yes, you can use aluminum foil facing to make a fish basket. Start by cutting a large piece of aluminum foil and folding it in half. Create a base by folding the edges up to form a shallow bowl shape. Then, fold the sides up and around, gradually narrowing the width to create the sides of the basket. Continue this process until you reach the desired height, ensuring the sides are sturdy enough to hold the fish. Seal the top with a final fold to complete the basket. This makeshift fish basket can be used for cooking or serving fish, but it's not recommended for heavy use or sharp objects due to the fragility of aluminum foil.</p>

Send your message to us

Nitrile Rubber Foam Insulation Sheet with Aluminum Foil Facing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords