Aluminum F Molding Extrusion Profiles - Well Structured and High Quality Aluminium Profiles

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

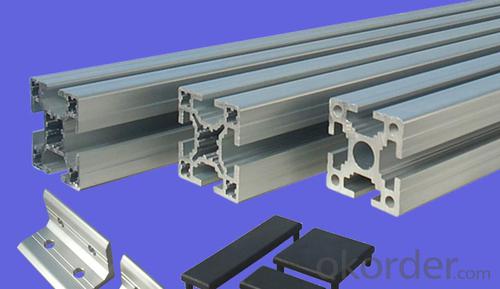

1.Structure of Aluminium Profile of Well Sturctured and Good Quality Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profile of Well Sturctured and Good Quality:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

3.Aluminium Profile of Well Sturctured and Good Quality Images:

4.Aluminium Profile of Well Sturctured and Good Quality Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the manufacturers of aluminum profiles in Jiangsu and Jiangyin?

- Hello, I do not know if you have any requirements to the region, if not, you can consider the manufacturers here in Foshan?Industrial aluminum extrusion machine operation rules and precautions (looking for aluminum profiles manufacturers search: "Foshan bright silver custom")First from the process analysis:1. open aluminum extrusion machine, must ensure that equipment around and on the machine no debris, oil2. prepare the material according to the production request, and then pour into the tank according to the proportion3. check the power status and acknowledge the normal operation of the control cabinet

- Q: Surface treatment method of aluminium profile

- Five most common surface treatment methods for aluminum profilesFabric: Aluminum matte matte surface aluminum profile Aluminum Alloy to avoid the presence of light interference will form light environment, under the condition of building decoration in the shortcomings of its surface such as brocade as soft and delicate, very popular with the favor of the market, but the existing grinding material must overcome the uneven surface of the sand, and can see the lack of pattern.Multi color surface treatment of aluminum: the monotonous white and tinted silver has been unable to meet the good cooperation of architects and the exterior decorative tile, exterior wall latex, new stainless steel color, champagne, gold, gold, titanium series (red wine, red jujube red, black, purple etc.) plus color glass the decorative effect of the icing on the cake. These shapes must be chemically or mechanically polished and then oxidized to better effect.Electrocoating aluminium profiles: electrophoretic coating profiles of surface soft luster, can resist the erosion of acid rain, cement mortar, Japan 90% aluminum after electrophoretic coating.Powder electrostatic spraying aluminum profile: powder electrostatic spraying profile is characterized by excellent corrosion resistance, acid, alkali, salt fog is much better than oxidation coloring section.Plasma enhanced electrochemical surface ceramic aluminum profile: this type of material is the most advanced processing technology in the world today. The profile products are of good quality, but the cost is higher. It has more than 20 kinds of colors, the biggest feature is that it can be printed as needed according to the printing cloth, the surface of the section is colourful and the decoration effect is excellent.

- Q: How are aluminum profiles cut and shaped?

- Aluminum profiles are cut and shaped using various methods such as sawing, milling, drilling, and bending. Sawing is the most common method, where a circular saw or bandsaw is used to cut the aluminum profiles to the desired length. Milling involves removing excess material using a rotating cutting tool to create specific shapes and designs. Drilling is used to create holes in the profiles using a drill bit. Lastly, bending is employed to shape the profiles by applying force to bend them into the desired angles or curves.

- Q: Can aluminum profiles be used for skylights?

- Yes, aluminum profiles can be used for skylights. Aluminum is a popular material choice for skylight frames due to its durability, strength, and resistance to corrosion. It is lightweight yet sturdy, making it suitable for supporting the weight of skylight glass while ensuring long-lasting performance. Additionally, aluminum profiles can be easily customized and shaped to meet specific design requirements, allowing for various skylight styles and sizes. The use of aluminum profiles in skylights also provides excellent thermal insulation properties, contributing to energy efficiency by reducing heat transfer and preventing condensation. Overall, aluminum profiles are a reliable and practical option for constructing skylights.

- Q: Are there any limitations or drawbacks to using aluminum profiles?

- Yes, there are some limitations and drawbacks to using aluminum profiles. Firstly, aluminum is a relatively soft metal compared to steel, which means it may not be as strong or durable in certain applications. Additionally, aluminum profiles can be more expensive than other materials such as wood or plastic. They also have lower resistance to high temperatures, which can lead to warping or deformation. Finally, aluminum profiles may require additional surface treatments or coatings to protect against corrosion in certain environments.

- Q: Can aluminum profiles be used in solar panel installations?

- Yes, aluminum profiles can be used in solar panel installations. Aluminum is a lightweight and durable material that is commonly used in the construction of solar panel frames. It offers excellent corrosion resistance and can withstand outdoor environmental conditions, making it suitable for long-term use in solar installations. Additionally, aluminum profiles can be easily fabricated and customized to fit specific panel sizes and mounting requirements.

- Q: What are the water-resistant properties of aluminum profiles?

- Aluminum profiles possess excellent water-resistant properties due to their natural oxide layer that forms on the surface. This oxide layer acts as a protective barrier, preventing the penetration of water molecules and inhibiting corrosion. Additionally, aluminum profiles can be further enhanced with various surface treatments such as anodizing, powder coating, or painting, which provide an additional layer of protection against water damage. These treatments not only enhance the aesthetic appeal of the profiles but also increase their resistance to water, making them suitable for outdoor applications or areas exposed to high humidity. Moreover, aluminum profiles have inherent structural integrity and dimensional stability, even in wet environments, making them a reliable choice for water-resistant applications such as windows, doors, and façade systems.

- Q: This question asks for a description of the various dimensions and forms of aluminum profiles that are utilized in siding systems.

- <p>Aluminum profiles for siding systems come in a variety of sizes and shapes to accommodate different architectural styles and structural requirements. Common profiles include flat bars, channels, angles, and Z-profiles. Sizes can range from narrow trims of 10mm to wide panels of over 200mm in width, with thicknesses typically from 0.5mm to 3mm. Shapes are designed for specific functions, such as interlocking for a seamless appearance, or with grooves for attaching insulation. Custom profiles are also available for unique applications. These profiles are chosen based on the building's design, load-bearing needs, and aesthetic preferences.</p>

- Q: How do you attach accessories or components to aluminum profiles?

- Accessories or components can be attached to aluminum profiles using various methods such as screws, bolts, brackets, clamps, connectors, or adhesive tapes. These attachment methods ensure a secure and sturdy connection between the accessories and the aluminum profiles, allowing for easy assembly and disassembly when needed.

- Q: Where is the aluminum profile market in Nanjing? Specific address, bus route

- Aluminum does not have the corresponding market basically, basically in Nanjing to do a relatively large Nanjing Meida aluminum, Nanjing Heng aluminium, yum Nanjing aluminum, Nanjing to build up the aluminum industry, basically is the nature of the company, you can go directly to their website to search their own needs aluminum.

Send your message to us

Aluminum F Molding Extrusion Profiles - Well Structured and High Quality Aluminium Profiles

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords